Unit coolers, Condensate drain lines, Field wiring – Heatcraft Refrigeration Products Unit Coolers H-IM-UC User Manual

Page 5: Check out and start up

5

Unit Coolers

Condensate Drain Lines

Either copper or steel drain lines should be used and properly protected

from freezing. In running drain lines, provide a minimum 1/4 inch per

foot pitch for proper drainage. Drain lines should be at least as large

as the evaporator drain connection. All plumbing connections should

be made in accordance with local plumbing codes. All condensate

drain lines must be trapped, and run to an open drain. They must

never be connected directly to the sewer system. Traps in the drain

line must be located in a warm ambient. We recommend a trap on

each evaporator drain line prior to any tee connections. Traps located

outside, or extensive outside runs of drain line must be wrapped with

a drain line heater. The heater should be connected so that it operates

continuously. It is recommended that the drain line be insulated to

prevent heat loss. A heat input of 20 watts per linear foot of drain line

for 0˚F (-18˚C) room applications and 30 watts per linear foot for -20˚F

(-29˚C) rooms is satisfactory. In freezers, the evaporator drain pan fitting

should be included when heating and insulating the drain line.

Inspect drain pan periodically to insure free drainage of condensate.

If drain pan contains standing water, check for proper installation. The

drain pan should be cleaned regularly with warm soapy water.

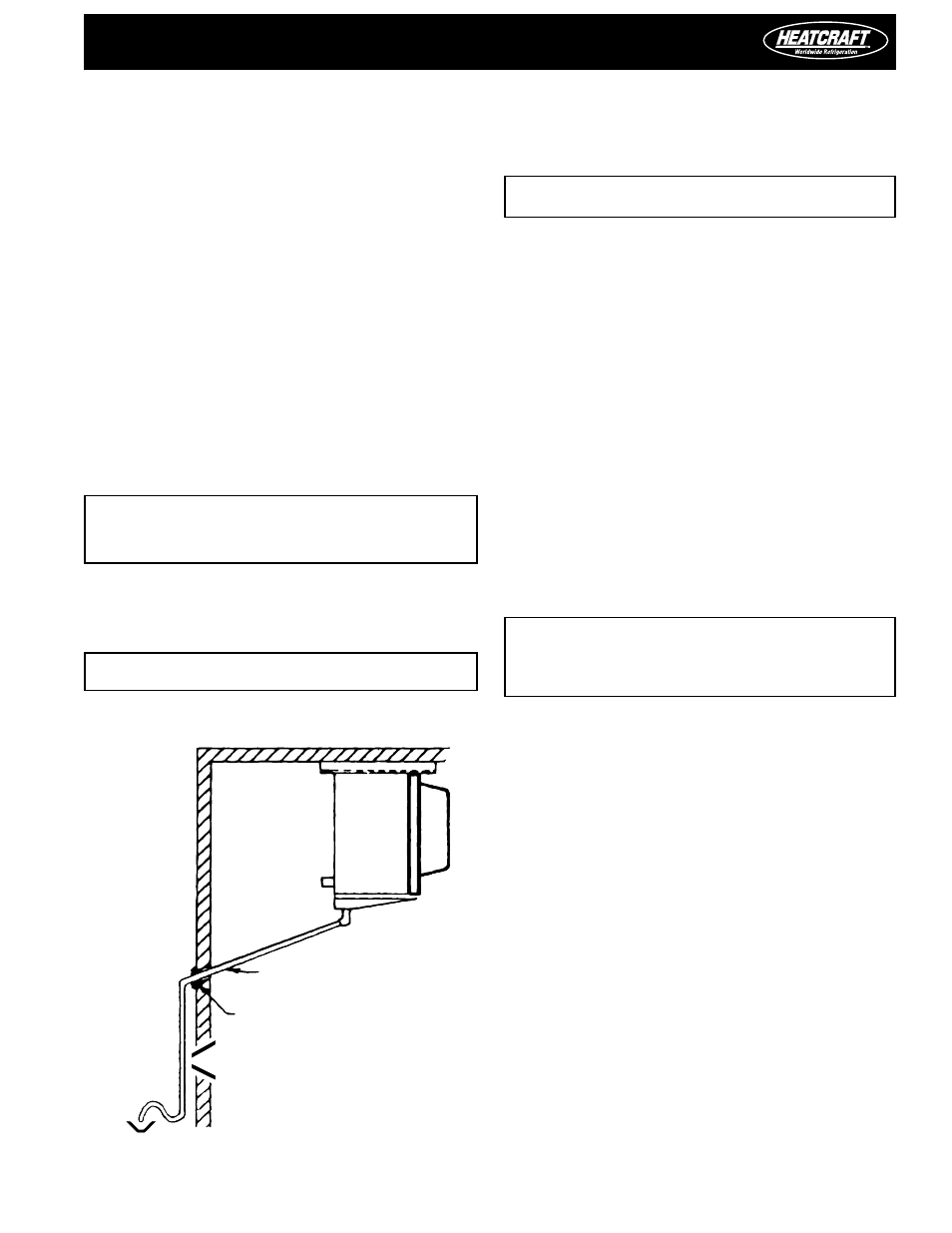

Figure 5. Condensate Drain Lines

DRAIN LINE MIN.

PITCH - 1/4”/ FT.

VAPOR SEAL

TRAP

OPEN

DRAIN

Traps on low temperature units must be outside of refrigerated

enclosures. Traps subject to freezing temperatures must be wrapped

with heat tape and insulated.

Field Wiring

The field wiring should enter the areas as provided on the unit. The

wiring diagram for each unit is located on the inside of the electrical

panel door. All field wiring should be done in a professional manner

and in accordance with all governing codes. Before operating unit,

double check all wiring connections, including the factory terminals.

Factory connections can vibrate loose during shipment.

1.

The serial data tag on the unit is marked with the electrical

characteristic for wiring the unit.

2.

Consult the wiring diagram in the unit cooler and in the con-

densing unit for proper connections.

3.

Wire type should be of copper conductor only and of the

proper size to handle the connected load.

4.

The unit must be grounded.

5.

For multiple evaporator systems, the defrost termination

controls should be wired in series. Follow the wiring diagrams

for multiple evaporator systems carefully. This will assure

complete defrost of all evaporators in the system.

6.

Multiple evaporator systems should operate off of one ther-

mostat.

7.

If a remote defrost timer is to be used, the timer should be

located outside the refrigerated space.

Check Out and Start Up

NOTE: All adjustable controls and valves must be field

adjusted to meet desired operation. There are no

factory preset controls or valve adjustments. This

includes low pressure, high pressure, adjustable

head pressure systems and expansion valves.

After the installation has been completed, the following points should

be covered before the system is placed in operation:

(a) Check all electrical and refrigerant connections.

Be sure they are all tight.

(b) Check the room thermostat for normal operation

and adjust.

(c) Wiring diagrams, instruction bulletins, etc. attached

to the condensing units should be read and filed for

future reference.

(d) All fan motors on evaporators should be checked for

proper rotation. Fan motor mounts should be carefully

checked for tightness and proper alignment.

(e) Electric and hot gas evaporator fan motors should

be temporarily wired for continuous operation until

the room temperature has stabilized.

(f) Do not leave unit unattended until the system has

reached normal operating conditions and the oil

charge has been properly adjusted to maintain the oil

level between 1/4 and bottom of the sight glass.

(g) Make sure all Schrader valve caps are in place and tight.

WARNING: All wiring must be done in accordance with

applicable codes and local ordinances.

WARNING: All power must be disconnected before clean-

ing. Drain pan also serves as cover of hazard-

ous moving parts. Operation of unit without

drain pan constitutes a hazard.

NOTE: Always trap single evaporator system drain

lines individually to prevent humidity migration.