Warning, Caution, Installation – Honeywell F116 User Manual

Page 7: Static pressure, When installing this product, Choose location and mount

F116 (SERIES 16000) SELF-CONTAINED DUCTABLE COMMERCIAL AIR CLEANER

7

68-0200-2

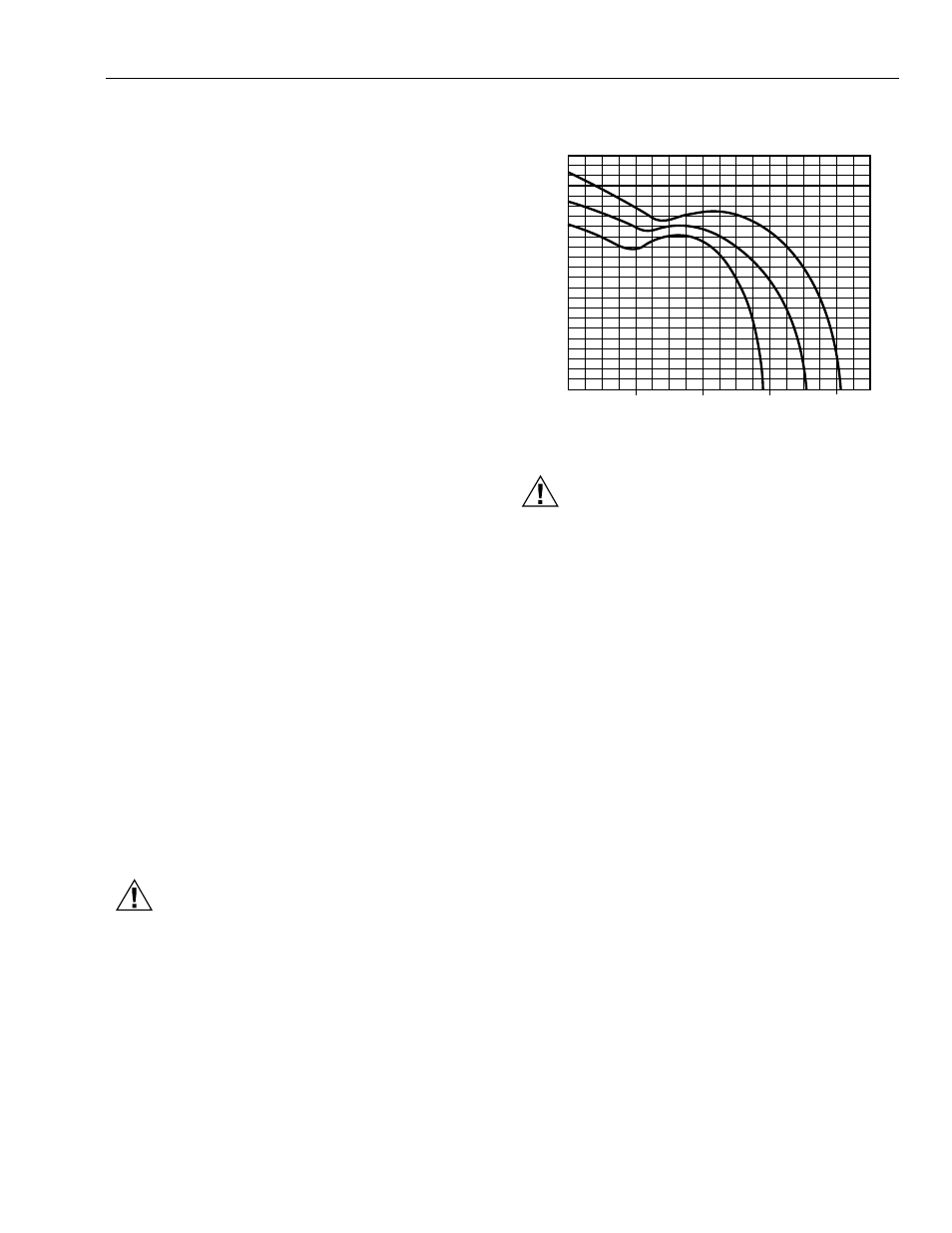

Static Pressure

The F116 (series 16000) uses a forward curve blower/

motor. The electrical current draw is determined by

combining the air volume to be moved with the filter and

ducting static pressure.

IMPORTANT

Motor overload will occur if the combined filter and

ducting static pressure is less than 1.2" W.G.

The net air volume at 1.2" W.G. will vary from 2150 cfm (62

m

3

/min) on low speed to 2350 cfm (68 m

3

/min) on high

speed. The maximum allowable electrical current draw for all

speeds is between 13.5A and 14A at 120 Vac.

The blower turns off when a sufficient amount of air can not be

drawn through the intake (1.85" W.G.) and the blower spins in a

vacuum. A maximum blower pressure of 2.25" W.G. can occur

which can have an air volume of 100 cfm (3 m

3

/min).

NOTE:

No damage will occur to the air cleaner if operating

at 1.85" W.G. pressure or higher.

The ideal system design has the ducting pressure combined

with a clean filter pressure operating at 1.2" W.G. The motor

should run at 14A at 120V. As the filters load, the resistance

to airflow increases which causes the static pressure to

increase while the electrical current draw and air volume

decrease. The air volume loss is low for the first 0.5" W.G. of

pressure increase from the initial 1.2" W.G.

EXAMPLE:

At high speed the 1.2" W.G. air volume is

approximately 2350 cfm (68 m

3

/min) and at 1.7"

W.G. the air volume is approximately 2000 cfm

(58 m

3

/min). But at 1.9" W.G. the air volume

drops to approximately 1150 cfm (33 m

3

/min).

Loading does not resist airflow when using the CPZ™

modules. However, a loaded prefilter does restrict the airflow.

Refer to Fig. 3 and Table 3 for nominal air volume

calculations and filter configuration pressures.

INSTALLATION

When Installing this Product…

WARNING

•

Remove packing materials from Blower Wheel

prior to installation or initial power on.

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

800

(23)

1200

(35)

1600

(46)

2000

(58)

2400

(70)

1.000

1.100

1.200

1.300

1.400

1.500

1.600

1.700

1.800

1.900

2.000

2.200

STATIC PRESSURE (INCHES W.G.)

FLOW RATE IN CFM (M

3

/MIN)

FAN PERFORMANCE

DIRECT DRIVE BLOWER (12-5/8 x 9-1/2 WHEEL)

TESTED WITH 3 FT (0.9M) OUTLET DUCT

M10794

Fig. 3. Fan performance.

CAUTION

•

Do not connect the power source until after the air

cleaner is mounted. This will prevent electrical

shock or equipment damage.

•

Be sure to turn off the air cleaner before servicing

it.

•

If the air cleaner must be turned on for an

electrical check, be extremely careful to avoid

electrical shock. Also, take care when working

near the air cleaner moving parts.

Choose Location and Mount

Choose a location that is readily accessible for regular

inspection and cleaning. Allow enough room for removing the

prefilter and primary filters. Be sure there is room for

servicing without removing pipes, ducts or other heating

system components. See Fig. 4 through 12 for suggested

locations.

The air cleaner must be attached to a structure capable of

supporting the weight of the unit with filters, ducting and

plenums when used. Roof trusses, bar joists and floor

joists are examples of suitable structures.

IMPORTANT

All suspension points (either six or eight depending

on the model) must be used for proper and safe

installation. See Fig. 1 and 2 for dimensions

between the suspension points.

Threaded rod, eyebolts with chains, or any standard practice

and hardware for handing method can be used in the

suspension of the air cleaner. See Fig. 13.