User-maintenance instructions, Cleaning maintenance and lubrication, Troubleshooting – Harbor Freight Tools 66305 User Manual

Page 11

Page 11

SKU 66305

for technical questions, please call 1-800-444-3353.

uSer-Maintenance

inStructionS

Procedures not specifically

explained in this manual

must be performed only by a

qualified technician.

to preVent

SeriouS injury

froM tooL faiLure:

do not use damaged

equipment. if abnormal noise,

vibration, or leaking air

occurs, have the problem

corrected before further use.

cleaning Maintenance and

Lubrication

note: These procedures are in addition to

the regular checks and maintenance

explained as part of the regular op-

eration of the air-operated tool.

Weekly - pivot point Lubrication

1.

and Safety inspection:

Lubricate the pivot points of the tool,

using white lithium grease. Inspect for

loose fasteners or any damage to the

Lift. Repair immediately or mark “Out

of Service” until repairs are made.

If the Hydraulic Ram fades or fails to

2.

lift you may need to add oil or purge

the Ram.

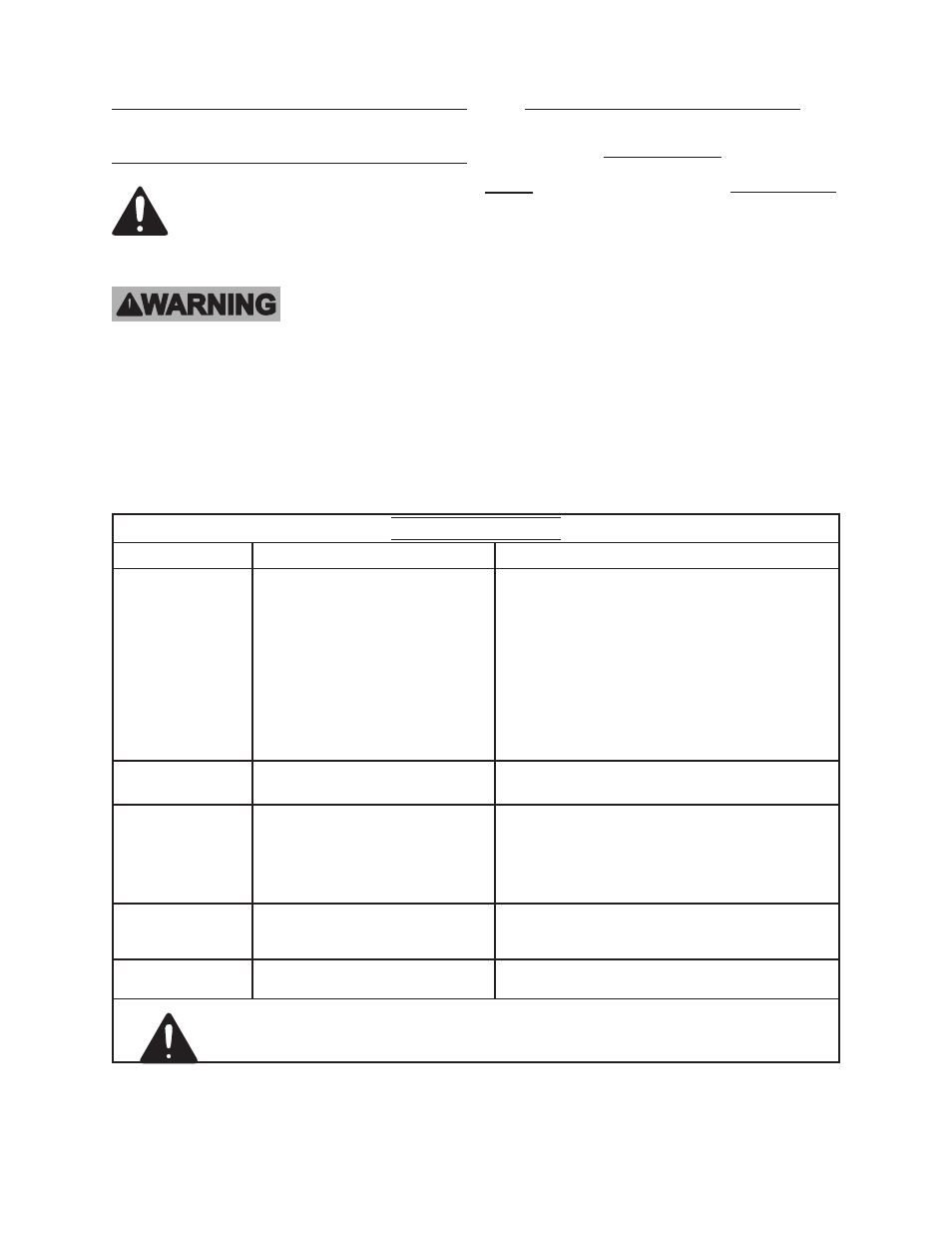

troubleshooting

possible causes

Likely Solutions

Motorcycle Lift does

not lift

Steel Ball (13a) in the Discharge

1.

Valve or the single-way valve of

the Hydraulic Cylinder does not

seat or seal well.

Steel Ball (13a) in the Single-way

2.

valve does not seat or seal well.

Hydraulic Ram may require

3.

purging.

Discharge Valve is open.

4.

Clean or replace these components.

1.

Clean or replace these components.

2.

Purge Ram. See instructions on page 6.

3.

Tighten the discharge valve.

4.

Motorcycle Lift

does not lower

Discharge Valve is not open

1.

Check function of Release Linkage Assembly

1.

(54).

Motorcycle Lift

Fades (slowly

lowers on its own)

Leaking Valves or Seals.

1.

Low on oil in system.

2.

Hydraulic Cylinder may require

3.

purging.

Take to qualified repair technician for service

1.

Check oil level. Refill and purge as necessary.

2.

Follow instructions for purging system.

Purge Hydraulic Ram. See instructions on page 6.

3.

Oil leaks from top

rod of Hydraulic

Ram (24).

Ram O-ring (2a or 6a) is worn

1.

out.

Replace the O-ring.

1.

Oil leaks from the

pump and cylinder

O-ring at pump (18a) or Oil Seal

1.

(3a or 10a) is worn out.

Replace the O-ring or Oil Seal.

1.

follow all safety precautions whenever diagnosing or servicing the tool.