Specifications, Save this manual, Safety warnings and precautions – Harbor Freight Tools 02665 User Manual

Page 2

Page 2

SKU 02665

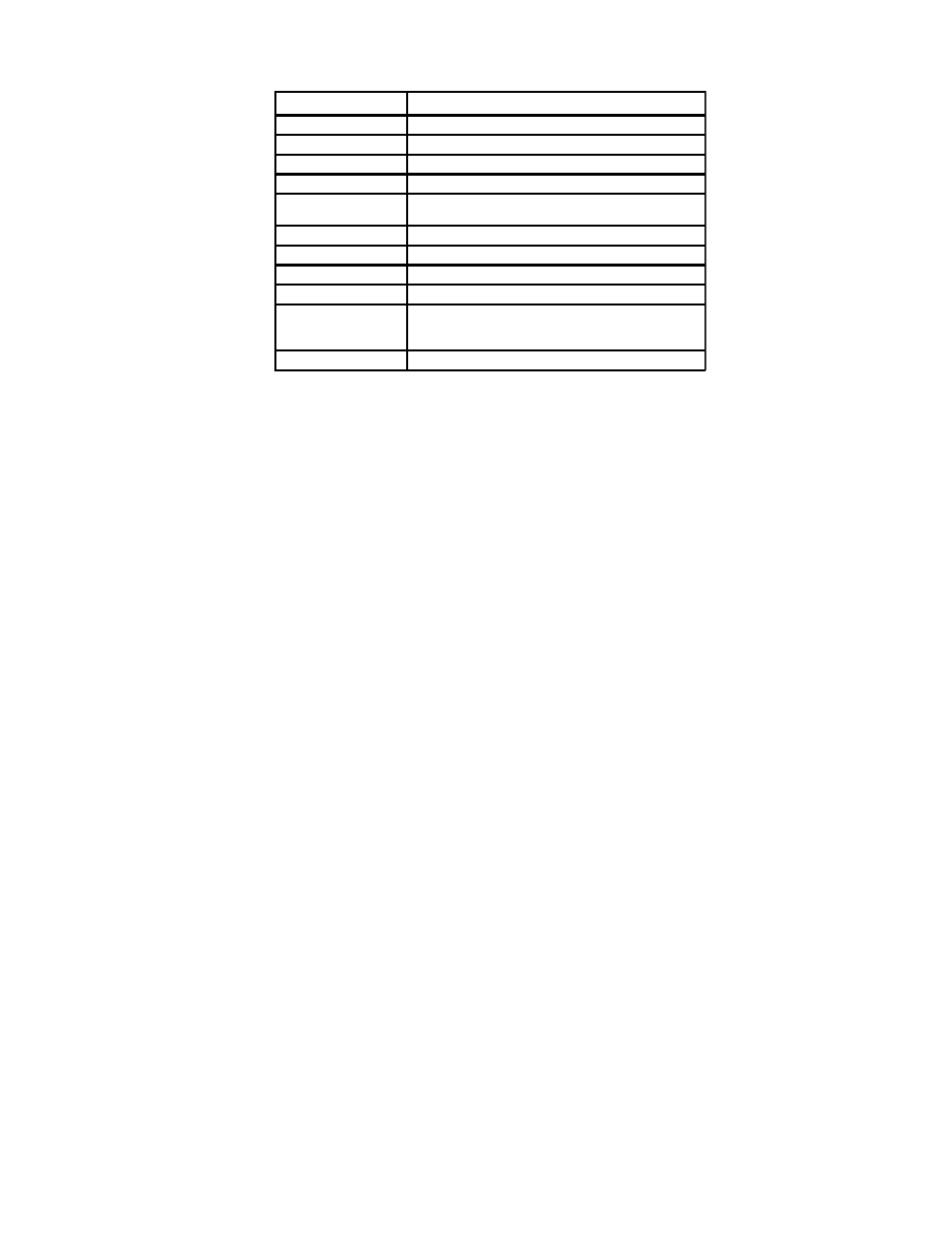

Specifications

ITEM

DESCRIPTION

Arc Welding Current

80 and 160 amp

Power Requirement

220 VAC, 40 amps, single phase, 60 Hz

Open Voltage

22 VAC at 80 amps; 28 VAC at 160 amps

Duty Cycle

40% at 80 amps; 10% at 160 amps

Thermal Overload

Protection

Automatic overload shutdown and reset

Dimensions

16 (L) x 6-7/8 (W) x 12-1/4 (H) inches

Ground Cable

4 AWG, single insulation, 6 foot

Torch Cable

4 AWG, single insulation, 6 foot

Power Cord

3-core, double insulated, 12 AWG, U.L. Approved

Features

Power switch with green light indicator

Thermal overload protection with red light indicator

AC output

Weight

55.8 lbs

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to re-

duce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1.

Keep work area clean. Cluttered areas invite injuries.

2.

Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3.

Keep children away. Children must never be allowed in the work area. Do not let them

handle machines, tools, or extension cords.

4.

Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5.

Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

6.

Use the right tool for the job. Do not attempt to force a small tool or attachment to do the

work of a larger industrial tool. There are certain applications for which this tool is designed.

It will do the job better and more safely at the rate for which it was intended. Do not

modify this tool and do not use this tool for a purpose for which it was not intended.

7.

Dress properly. Do not wear loose clothing or jewelry as they can be caught in moving

parts. Protective, electrically non-conductive clothes and non-skid footwear are

recommended when working. Wear restrictive hair covering to contain long hair.

8.

Use eye protection. Always wear ANSI approved impact safety glasses under an arc

shaded, welding helmet. Wear an ANSI approved dust mask or respirator when working