Hellenbrand TNT Series User Manual

Page 4

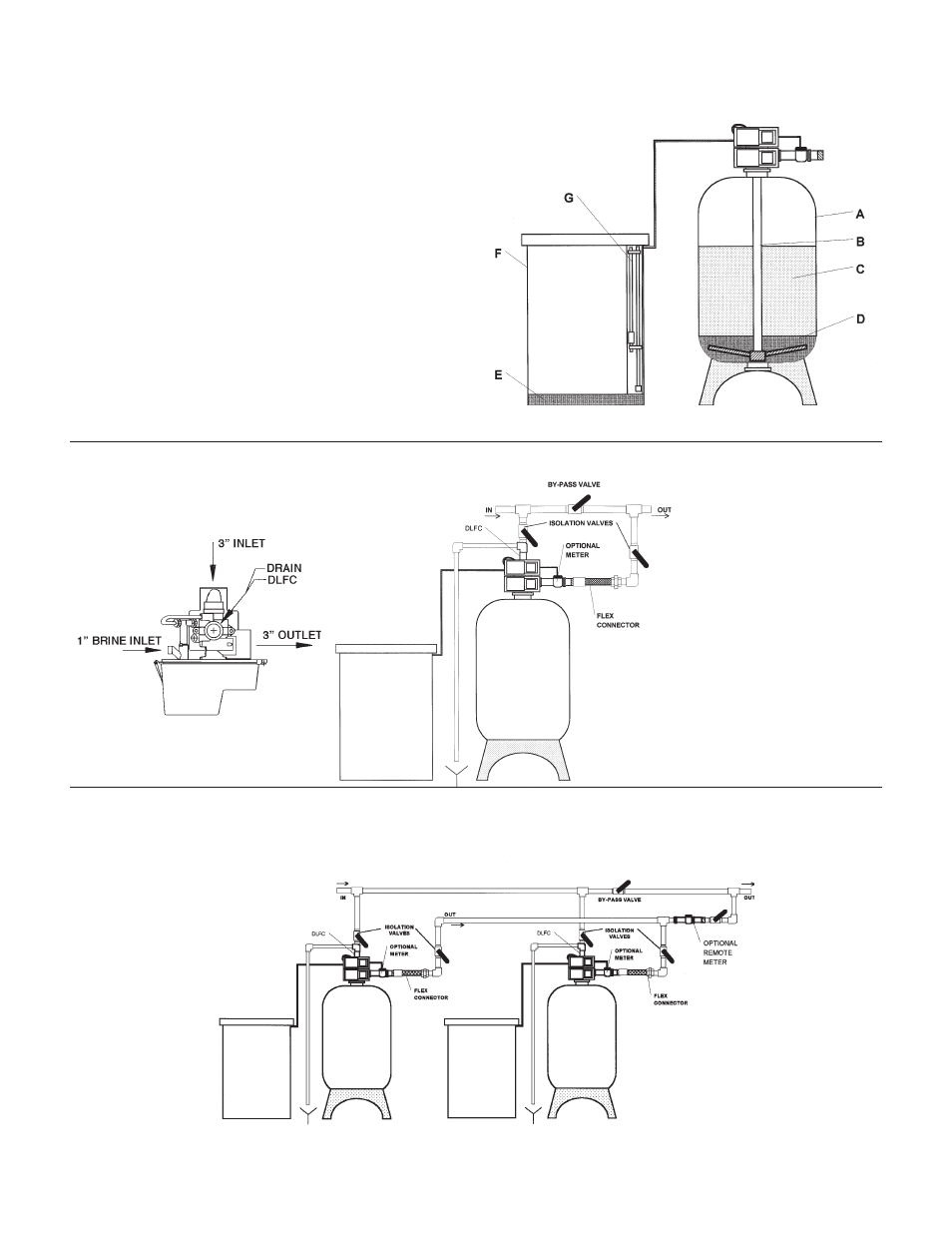

A

. MINERAL TANK: Poly Glass™ Composite tank with Poly-

ethylene Inner Shell and Fiberglass Roving Manufactured to

Operate at 150 psi. NSF Approved.

B. DISTRIBUTOR SYSTEM: Three-Inch Hub & Lateral Dis-

tribution for Maximum Service Flow and Minimal Pressure

Loss.

C. MINERAL: High Capacity Ion Exchange Resin. Uniform

and stable beads assure long life, high salt efficiency, and

maximum hardness removal.

D. UNDERBEDDING: Multi-Layered Gravel Underbedding

assures full usage of mineral bed and allows for a smooth

and constant water flow for service and regeneration.

E. BRINE TANK: Rotationally Molded Polyethylene with

Dust-tight cover.

F. GRID PLATE: Grid plate allows for dry salt storage. Avail-

able in various sizes and heights.

G. OPTIONAL SAFETY BRINE VALVE: Acts as a Second-

ary Shut-Off for Timed Brine and may be used as a Primary

Shut-Off without Timed Brine.

TNT Series

Typical Single Tank Installation

Twin Alternating Tank Installation

(Available with individual brine tanks as shown or with one twin brine tank.)

TOP VIEW

Note:

1. Optional stainless steel flex connectors are available for the inlet and outlet connection with each system and

must be installed on systems utilizing Polyglass™ composite tanks with rigid piping in copper, galvanized...etc.

2. Union type connections are recommended on the inlet and outlet connections.

Note:

1. Optional stainless steel flex

connectors are available

for inlet and outlet connec-

tions. These are recom-

mended on systems utiliz-

ing Polylglass composite

tanks with rigid piping such

as copper, galvanized, ect.

2. Union type connections are

recommended on the inlet

and outlet connections.

Note: Steel tanks optional