Change engine oil, Maintenance, Warning – Exmark Commercial 21 4500-686 Rev. B User Manual

Page 28

Maintenance

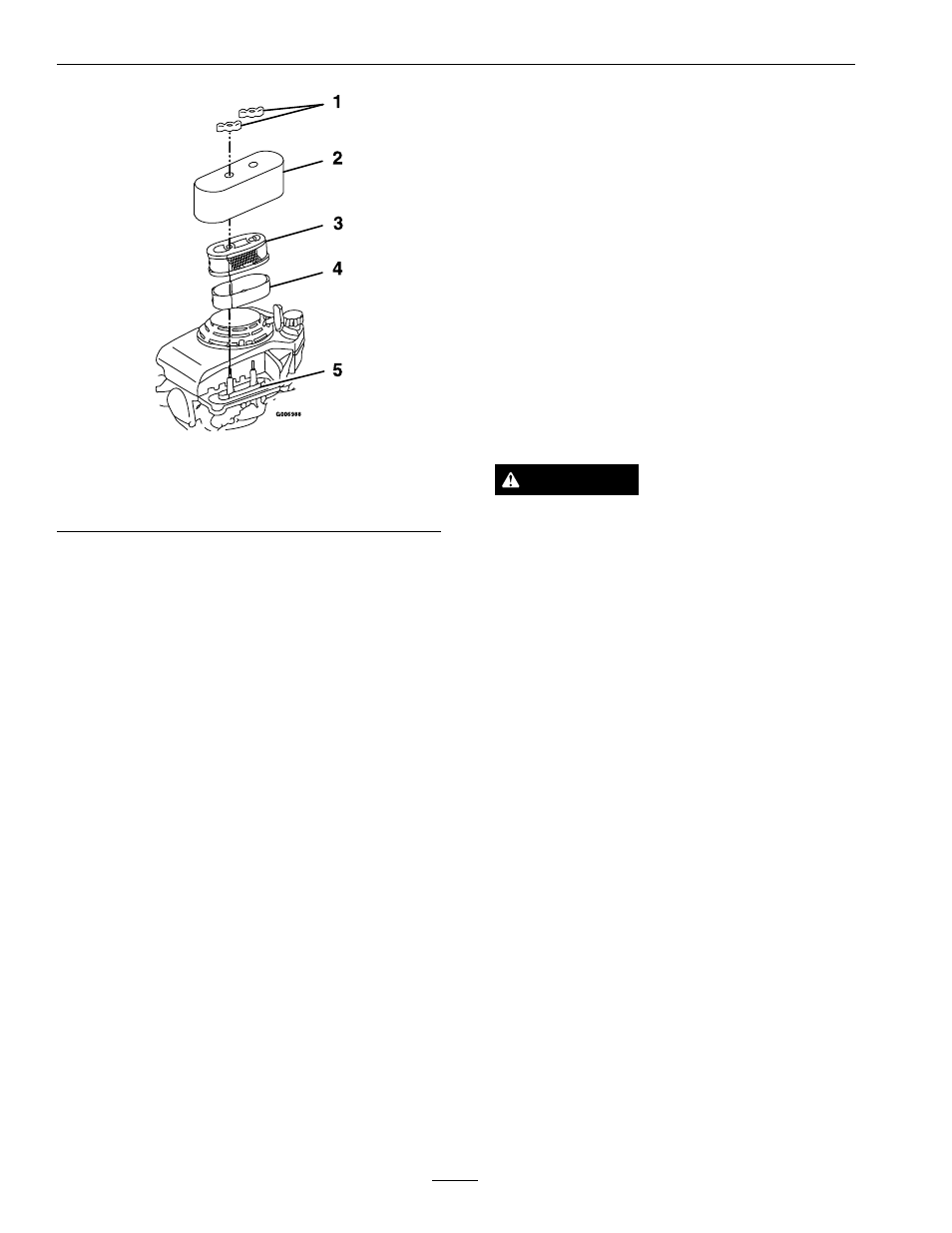

Figure 29

1.

Wing nuts

4.

Foam element

2.

Cover

5.

Base

3.

Paper element

4. Remove the cover.

Note: Be careful to prevent dirt and debris from

falling into the base.

5. Remove the foam and paper elements from the

base.

6. Remove the foam element from the paper

element.

7. Inspect the foam and paper elements, and replace

them if they are damaged or excessively dirty.

8. Tap the paper element on a hard surface several

times or use compressed air not exceeding 30

psi (207 kPa) through the filter from the wire

screen side to remove any excess dirt. If the paper

element is excessively dirty, replace it.

Note: Never try to brush dirt off the paper

element; brushing forces the dirt into the fibers.

9. Clean the foam element in warm, soapy water or

in a nonflammable solvent.

10. Rinse and dry the foam element thoroughly.

11. Dip the foam element in clean engine oil, then

squeeze out the excess oil.

Note: Excess oil in the foam element restricts

the air flow through the element and may reach

the paper filter and clog it.

12. Wipe dirt from the base and the cover with a

moist rag.

Note: Be careful to prevent dirt and debris from

entering the air duct leading to the carburetor.

13. Install the air cleaner elements and ensure that

they are properly positioned.

14. Securely install the cover with the two wing nuts.

Change Engine Oil

Service Interval: After the first 5 hours

Every 50 hours (May need

more often under severe

conditions.)

1. Run the engine to warm the engine oil.

Note: Warm oil flows better and carries more

contaminates.

WARNING

Oil may be hot after engine has been run.

Contact with hot oil can cause severe personal

injury.

Avoid contacting the hot engine oil when you

drain it.

2. Stop engine, wait for all moving parts to stop.

3. Disconnect the wire from the spark plug.

4. Drain the gasoline from the fuel tank. Refer to

Emptying the Fuel Tank and Cleaning the

Fuel Filter section.

5. Place a suitable drain pan under the dipstick/oil

drain.

6. Clean around the dipstick.

7. Remove the dipstick by rotating the cap

counterclockwise and pulling it out.

8. Raise the left side of the lawn mower to drain the

oil from the dipstick fill tube into the drain pan.

9. After draining the oil, return the lawn mower to

the operating position.

10. Fill the crankcase with fresh oil to the upper limit

mark on the dipstick. Use oil recommended in

the Check Engine Oil Level section. Do Not

overfill

11. Insert the dipstick into the filler neck and rotate

the cap clockwise until it is tight.

12. Wipe up any spilled oil.

28