Operating instructions, Control board functions – Enviro C-10825 User Manual

Page 6

Operating Instructions

C

ONTROL

B

OARD

F

UNCTIONS

:

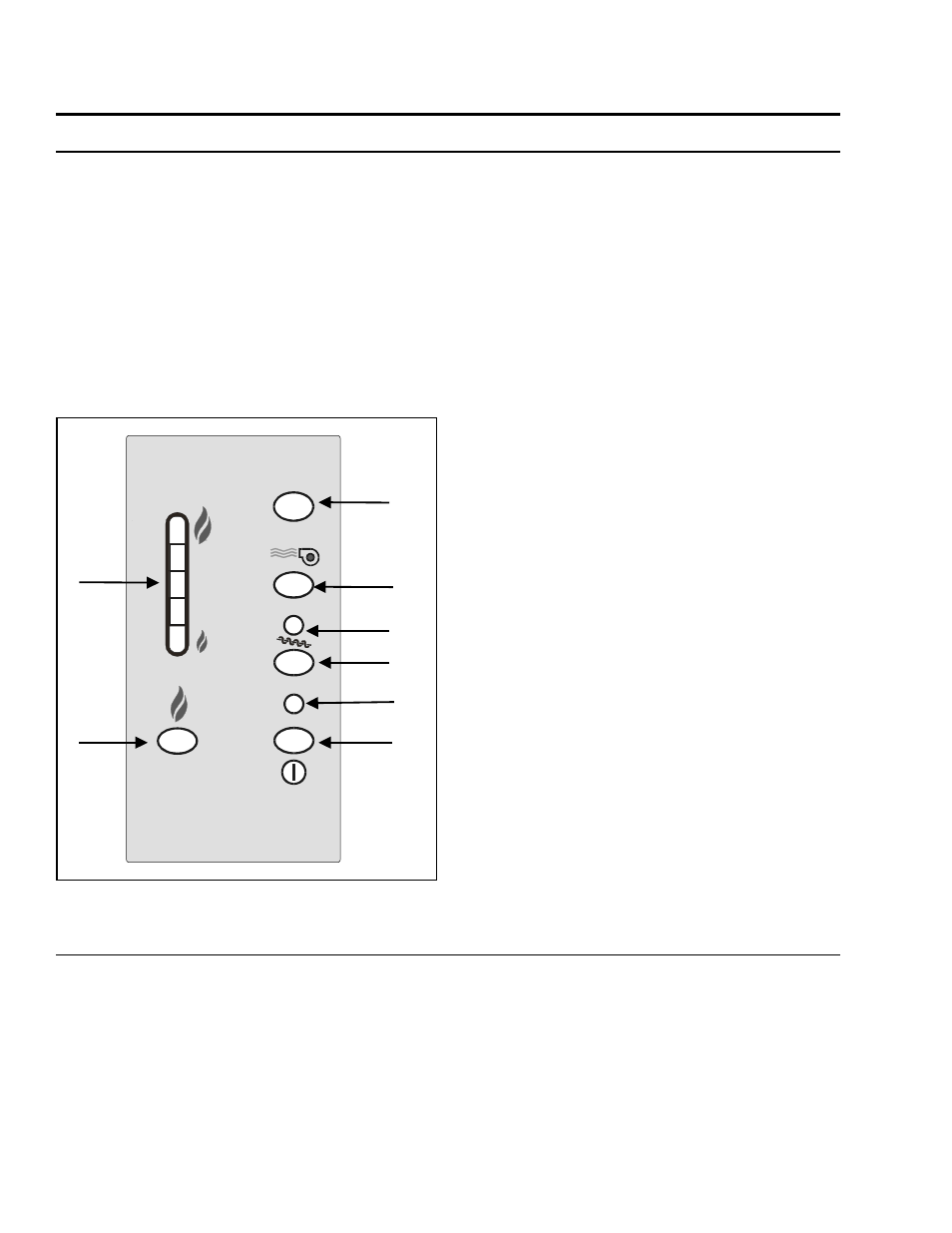

1. AUGER TRIM: Used to change feed rates on LOW ONLY for poorer quality fuels. Push the Auger

Trim button until the number 1 and 5 lights appear on the Heat Level Indicator. This will increase the

feed rate to 4 seconds ON time Auger pulse. This is done only on LOW to allow the burning of poor

quality fuels. Push the button until the number 1 and 4 lights appear, this will reduce the Auger On

time to 2 second. This setting is for high-grade fuel only. Push the button until just the number 1

light is on, this is for a three (3) second on time (standard setting).

2. CONVECTION BLOWER CONTROL: Used to turn the convection blower ON/OFF. Leave the

convection blower ON for peak efficiency

3. AUGER PULSE LIGHT: This light will flash in conjunction with the auger.

AUGER TRIM

FAN

MANUAL FEED

ON/OFF

HEAT LEVEL

�

�

�

�

�

�

�

�

4. MANUAL AUGER FEED: If the unit runs out

of fuel, this button can be used to “prime the

auger system”. This button will turn off after 60

seconds and then must be released and pressed

again.

5. SYSTEM LIGHT: Responsible for signaling

the state of the control board. When the light

is flashing during start-up, the stove is in an

automatic start mode. When the light is solid,

the Heat Level Setting can be altered.

6. ON/OFF BUTTON: Used to turn the unit ON

and OFF.

7. HEAT OUTPUT INDICATOR: Shows the

present heat output setting.

8. HEAT LEVEL ADJUSTMENT: When pressed,

will change the heat setting of the unit from

low to high.

6

Figure 1: Circuit Board Control Panel Decal

A

UTOMATIC

S

AFETY

F

EATURES

OF

Y

OUR

P

ELLET

S

TOVE

:

A. The stove will shut off when the fire goes out and the exhaust temperature drops below 120°F

(49°C).

B. The stove has a high temperature safety switch. If the temperature on the hopper reaches 200°F

(93°C), the auger will automatically stop and the stove will shut down when the exhaust temperature

cools. If this happens, call your local dealer to reset the 200°F (93°C) high limit switch. ALSO FIND

THE REASONS WHY THE UNIT OVERHEATED.