Figure 12 checking gas connections, Pressure testing heater gas connections, Figure 13 – Enerco HSVFR10LPT User Manual

Page 9: Figure 14

9

Installation Instructions and Owner’s Manual

Unvented Liquid Propane Fired Room Heater

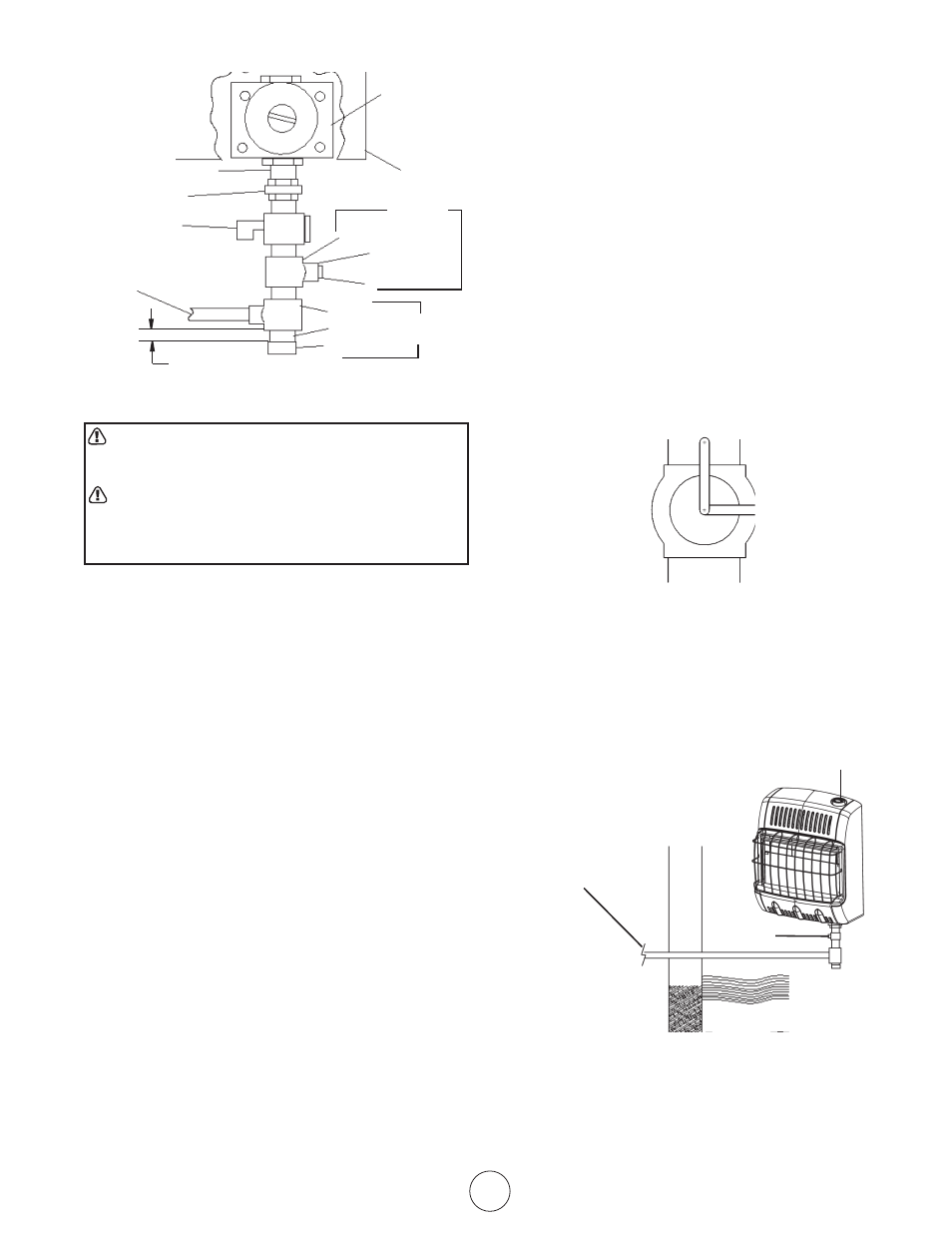

Figure 12

CHECKING GAS CONNECTIONS

WARNING: Test all gas piping and connections for

leaks after installing or servicing. Correct all leaks

at once.

WARNING: Never use an open flame to check for

a gas leak. Apply a mixture of liquid soap and water

to all joints. Bubbles forming show a leak. Correct

all leaks at once.

PRESSURE TESTING GAS SUPPLY PIPING

SYSTEM

High Pressure

Test pressure in Excess of ½ psig (3.5kPa)

1. Disconnect appliance with its appliance main

gas valve (control valve) and equipment shutoff

valve from gas supply piping system. Pressures

in excess of ½ psig will damage heater regula-

tor.

2. Cap off open end of gas pipe where equipment

shutoff valve was connected.

3. Pressurize supply piping system by either using

compressed air or opening main gas valve on

or near gas meter.

4. Check all connections and joints in gas supply

piping system. Apply mixture of liquid soap and

water to gas joints. Bubbles forming show a

leak.

5. Correct all leaks at once.

6. Depressurize and relieve pressure in supply

piping system.

7. Reconnect heater and equipment shutoff valve

to gas supply.

8. Reconnected fittings must be checked for leaks

in next section.

Low Pressure

Test Pressure Equal To or Less Than ½ psig (3.5

kPa)

1. Close equipment shutoff valve (see figure 13).

2. Pressurize supply piping system by either using

compressed air or opening propne/LP supply

valve.

3. Check all joints from the propane/LP supply

valve to equipment shutoff valve (see figure

14). Apply mixture of liquid soap and water to

gas joints. Bubbles forming show a leak.

4. Correct all leaks at once.

5. Depressurize and relieve pressure from supply

piping system.

Pressure Testing Heater Gas Connections:

1. Make sure that the heater supply piping sys-

tem is connected and has been leak tested as

described above.

2. Make sure control knob of heater is in OFF

position.

Figure 13

3. Open equipment shutoff valve (see figure 13).

4. Open propane/LP supply valve.

5. Check all joints from equipment shutoff valve

to control valve (see figure 14). Apply mixture

of liquid soap and water to gas joints. Bubbles

forming show a leak.

Figure 14

6. Correct all leaks at once.

7. Light heater (see Operating Your Heater, page

page 10.

Equipment

Shutoff Valve

Open

Closed

Pressure

Regulator

Heater

Cabinet

Ground Joint Union

Equipment

Shutoff Valve

From LP tank

(11” W.C. to 14”

W.C. Pressure)

Tee Joint

1/8” NPT Plug Tap

Cap

Pipe Nipple

Tee Joint

3/8” NPT Pipe Nipple

Sediment

Trap

Test Gauge

Connection

Reducer Bushing

to 1/8” NPT

3” Minimum

Control Valve

Equipment

Shutoff Valve

To regulated propane

source