Table 13: static resistances, Table 14: power exhaust performance, Table 15: blower motor and drive data – Energy Tech Laboratories DHG240 User Manual

Page 18

035-17233-000-C-0702

18

Unitary Products

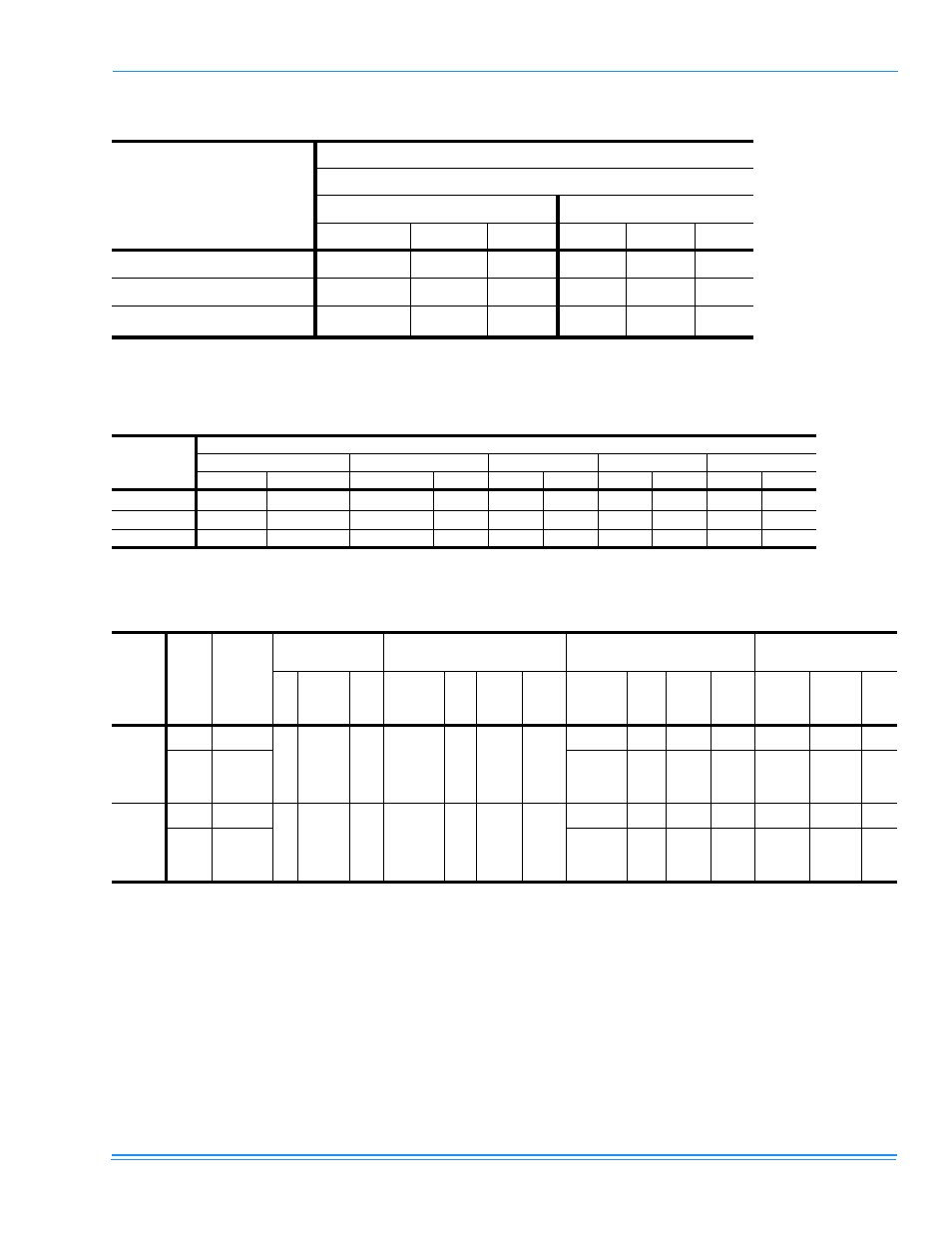

TABLE 13: STATIC RESISTANCES

1

DESCRIPTION

RESISTANCE, IWG

CFM

15 TON

20 TON

4500

5765

7200

6000

7000

9400

WET COIL

0.1

0.1

0.1

0.1

0.1

0.1

ECONOMIZER OPTION

0.1

0.1

0.1

0.1

0.1

0.1

HORIZONTAL DUCT CONN.

2

0.2

0.3

0.5

0.2

0.3

0.5

1

Deduct these resistance values from the available unit ESP values listed in the respective blower per-

formance table except for Horizontal Duct Connections.

2

Add these values due to less airflow resistance.

TABLE 14: POWER EXHAUST PERFORMANCE

MOTOR

SPEED

1

STATIC RESISTANCE OF RETURN DUCTWORK, IWG

0.2

0.3

0.4

0.5

0.6

CFM

kW

CFM

kW

CFM

kW

CFM

kW

CFM

kW

HIGH

2

5250

0.83

4500

0.85

4200

0.88

3750

0.93

3000

0.99

MEDIUM

4900

0.77

3900

0.79

3500

0.82

2900

0.85

-

-

LOW

4400

0.72

3700

0.74

3000

0.78

-

-

-

-

1

Power exhaust motor is a 3/4 HP, PSC type with sleeve bearings, a 48 frame and inherent protection.

2

The factory setting.

TABLE 15: BLOWER MOTOR AND DRIVE DATA

MODEL

SIZE

DRIVE

BLWR

RANGE

(RPM)

MOTOR

1

ADJ. MOTOR PULLEY

FIXED BLOWER PULLEY

BELT

(NOTCHED)

HP FRAME

EFF.

(%)

DESIGN-

NATION

O/D

(in.)

PITCH

DIA

(in.)

BORE

(in.)

DESIGN-

NATION

O/D

(in.)

PITCH

DIA

(in.)

BORE

(in.)

DESIG-

NATION

PITCH

LNGTH.

(in.)

QTY.

15 Ton

Std.

850/1065

5

184T

89.5

1VP56

5.35

4.3-

5.3

2

1-1/8

BK90

8.75

8.4

1

BX70

71.8

1

High

Spd.

Acs.

965/1190

BK80

7.75

7.4

1

BX68

69.8

1

20 Ton

Std.

870/1025

7.5

213T

91

1VP68

6.75

5.5-

6.5

2

1-3/8

BK120

11.75

11.4

1-3/16

BX83

84.8

1

High

Spd.

Acs.

950/1120

BK110

10.75

10.4

1-3/16

BX80

81.8

1

1

All motors have a nominal speed of 1800 RPM, a 1.15 service factor and a solid base. They can operate to the limit of their service

factor because they are located in the moving air, upstream of any heating device.

2

DO NOT close this pulley below 1 turn.