Gas supply – Empire Comfort Systems VFSR-24-3 User Manual

Page 13

26333-3-1210

Page 13

Check all local codes for requirements, especially for the size

and type of gas supply line required.

Notice

: Never use plastic pipe. Check to confirm whether

your local codes allow copper tubing or galvanized.

Notice

: Since some municipalities have additional local

codes, it is always best to consult your local authority and

installation code.

Installing a New Main Gas cock

Each appliance should have its own manual gas cock.

A manual main gas cock should be located in the vicinity of

the unit. Where none exists, or where its size or location is not

adequate, contact your local authorized installer for instal-

lation or relocation.

Compounds used on threaded joints of gas piping shall be

resistant to the action of liquefied petroleum gases. The gas

lines must be checked for leaks by the installer. This should

be done with a soap solution watching for bubbles on all

exposed connections, and if unexposed, a pressure test

should be made.

Never use an exposed flame to check for leaks. Appli-

ance must be disconnected from piping at inlet of control

valve and pipe capped or plugged for pressure test.

Never pressure test with appliance connected; control

valve will sustain damage!

A gas valve and ground joint union should be installed in the

gas line upstream of the gas control to aid in servicing. It is

required by the National Fuel Gas Code that a drip line be

installed near the gas inlet. This should consist of a vertical

length of pipe tee connected into the gas line that is capped

on the bottom in which condensation and foreign particles

may collect.

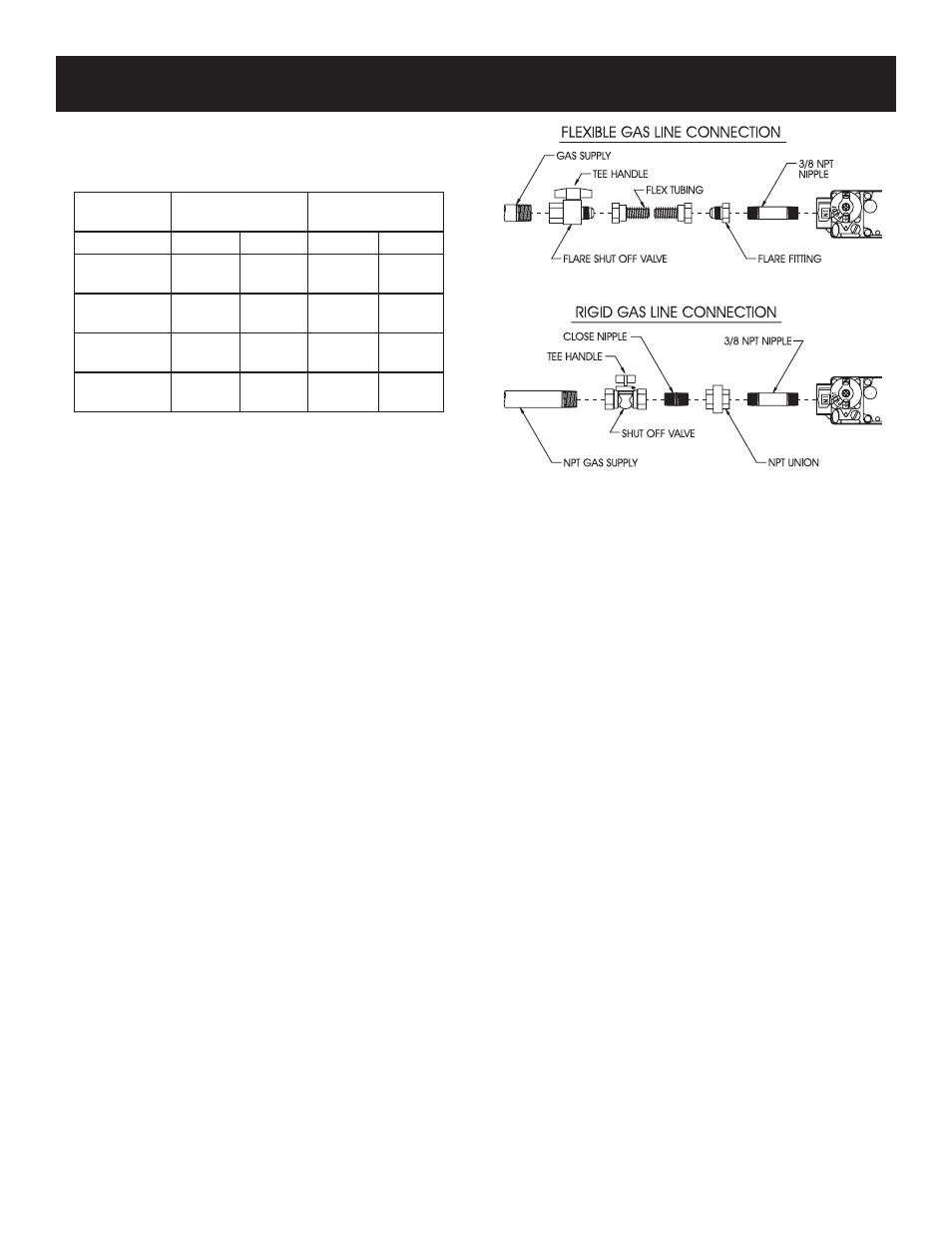

Figure 11

The use of the following gas connectors is recommended:

— ANS Z21.24 Appliance Connectors of Corrugated Metal

Tubing and Fittings

— ANS Z21.45 Assembled Flexible Appliance Connectors

of Other Than All-Metal Construction

The above connectors may be used if acceptable by the

authority having jurisdiction. The state of Massachusetts

requires that a flexible appliance connector cannot exceed

three feet in length.

Pressure Testing of the Gas Supply System

1. To check the inlet pressure to the gas valve, a 1/8"

(3.175mm) N.P.T. plugged tapping, accessible for test

gauge connection, must be placed immediately upstream

of the gas supply connection to the appliance.

2. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5 kPa).

3. The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig

(3.5 kPa).

Attention! If one of the procedures results in pressures in

excess of 1/2 psig (14" w.c.) (3.5 kPa) on the appliance gas

valve, it will result in a hazardous condition.

GAS SuPPLy

recommended Gas Pipe Diameter

Pipe Length

Schedule 40 Pipe

Inside Diameter

Tubing, Type L

Outside Diameter

Nat.

L.P.

Nat.

L.P.

0-10 feet

0-3 meters

1/2”

12.7mm

3/8”

9.5mm

1/2”

12.7mm

3/8”

9.5mm

10-40 feet

4-12 meters

1/2”

12.7mm

1/2”

12.7mm

5/8”

15.9mm

1/2”

12.7mm

40-100 feet

13-30 meters

1/2”

12.7mm

1/2”

12.7mm

3/4”

19mm

1/2”

12.7mm

100-150 feet

31-46 meters

3/4”

19mm

1/2”

12.7mm

7/8”

22.2mm

3/4”

19mm