Instruction manual – Emerson Process Management 667 User Manual

Page 11

Instruction Manual

D100311X012

667 Size 80 and 100 Actuators

May 2011

11

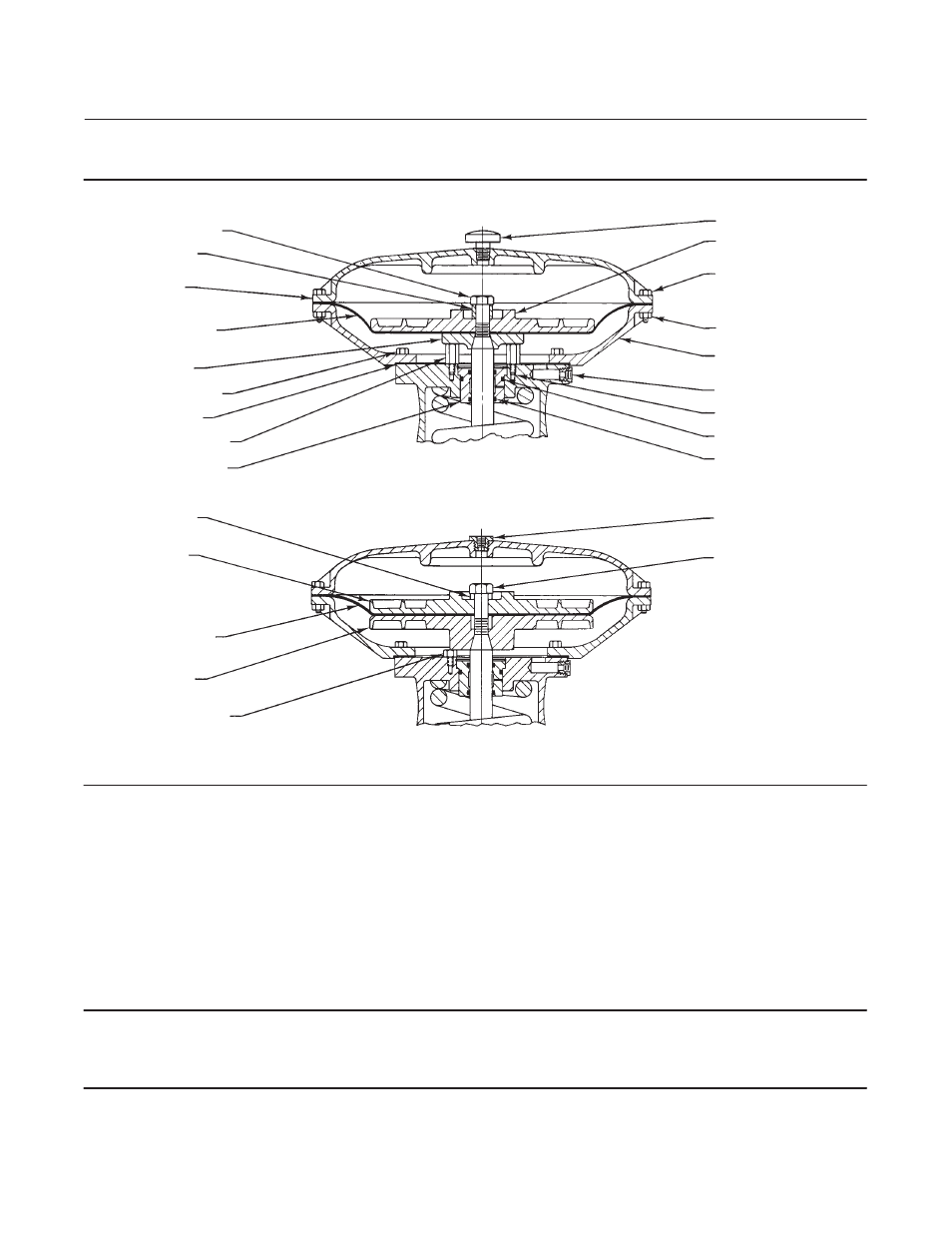

Figure 4. Size 80 Actuator Construction

CAP SCREW (KEY 12)

SPACER (KEY 2)

UPPER DIAPHRAGM

CASE (KEY 1)

DIAPHRAGM (KEY 3)

LOWER DIAPHRAGM

PLATE (KEY 71)

CAP SCREW (KEY 30)

GASKET (KEY 70)

TRAVEL STOP (KEY 84)

SEAL BUSHING (KEY 7)

VENT ASSEMBLY (KEY 17)

UPPER DIAPHRAGM

PLATE (KEY 4)

CAP SCREW (KEY 13)

HEX NUT (KEY 14)

LOWER DIAPHRAGM

CASE (KEY 64)

PIPE BUSHING (KEY 92)

SNAP RING (KEY 72)

O‐RING (KEY 9)

O‐RING (KEY 8)

SPACER (KEY 2)

UPPER DIAPHRAGM

PLATE (KEY 4)

DIAPHRAGM (KEY 3)

LOWER DIAPHRAGM

PLATE (KEY 71)

TRAVEL STOP (KEY 84)

PIPE BUSHING (KEY 78)

CAP SCREW (KEY 12)

STANDARD DIAPHRAGM CONSTRUCTION

TOP LOADED DIAPHRAGM CONSTRUCTION

50A8597‐D

50A8599-C

C0772 / IL

7. For actuators without a snubber, install the seal bushing (key 7) into the spring case adaptor (key 89) followed by

the snap ring (key 72). Replace the seal bushing O‐rings (keys 8 and 9) as required.

8. Coat the gasket (key 70) with lithium grease lubricant (key 237). Position the lower diaphragm casing (key 64) on

the spring case adaptor, and secure with cap screws (key 30).

9. Mount the lower diaphragm plate, diaphragm, upper diaphragm plate, and, if used, spacer (keys 71, 3, 4, and 2) on

the actuator stem (key 144), and secure using the cap screw (key 12). Coat the cap screw threads with lithium

grease (key 237). Tighten the cap screw (key 12) to 544 N

Sm (400 lbfSft).

Note

Standard and top‐loaded constructions use the same key numbers for parts. The parts look different, but they use the same

assembly and disassembly sequence. See figure 4, Size 80 Actuator Construction.