Adjusting table rollers – Epson 22-681 User Manual

Page 19

19

ADJUSTING SPRING TENSION OF

INFEED AND OUTFEED ROLLERS

The infeed and outfeed rollers are those parts of your

planer that feed the stock while it is being planed. The

feed rollers are under spring tension and this tension

must be sufficient to feed the stock uniformly through

the planer without slipping but should not be too tight

that it causes damage to the board. The tension should

also be equal at both ends of each roller.

To adjust the spring tension of the infeed roller, turn two

screws, one of which is shown at (A) Fig. 46. The other

screw is located on the opposite side of the machine. A

good starting point to use in setting the spring tension of

the infeed roller is to adjust the two screws (A) until there

are FOUR threads showing above the table casting. To

increase or decrease the spring tension further, adjust

screws (A).

To adjust the spring tension of the outfeed roller, turn

two screws, one of which is shown at (B) Fig. 46. The

other screw is located on the opposite side of the

machine. A good starting point to use in setting the

spring tension of the outfeed roller is to adjust the two

screws (B) until there is ONE thread showing above the

table casting. To increase or decrease the spring tension

further, adjust screws (B).

Fig. 46

Fig. 47

Fig. 48

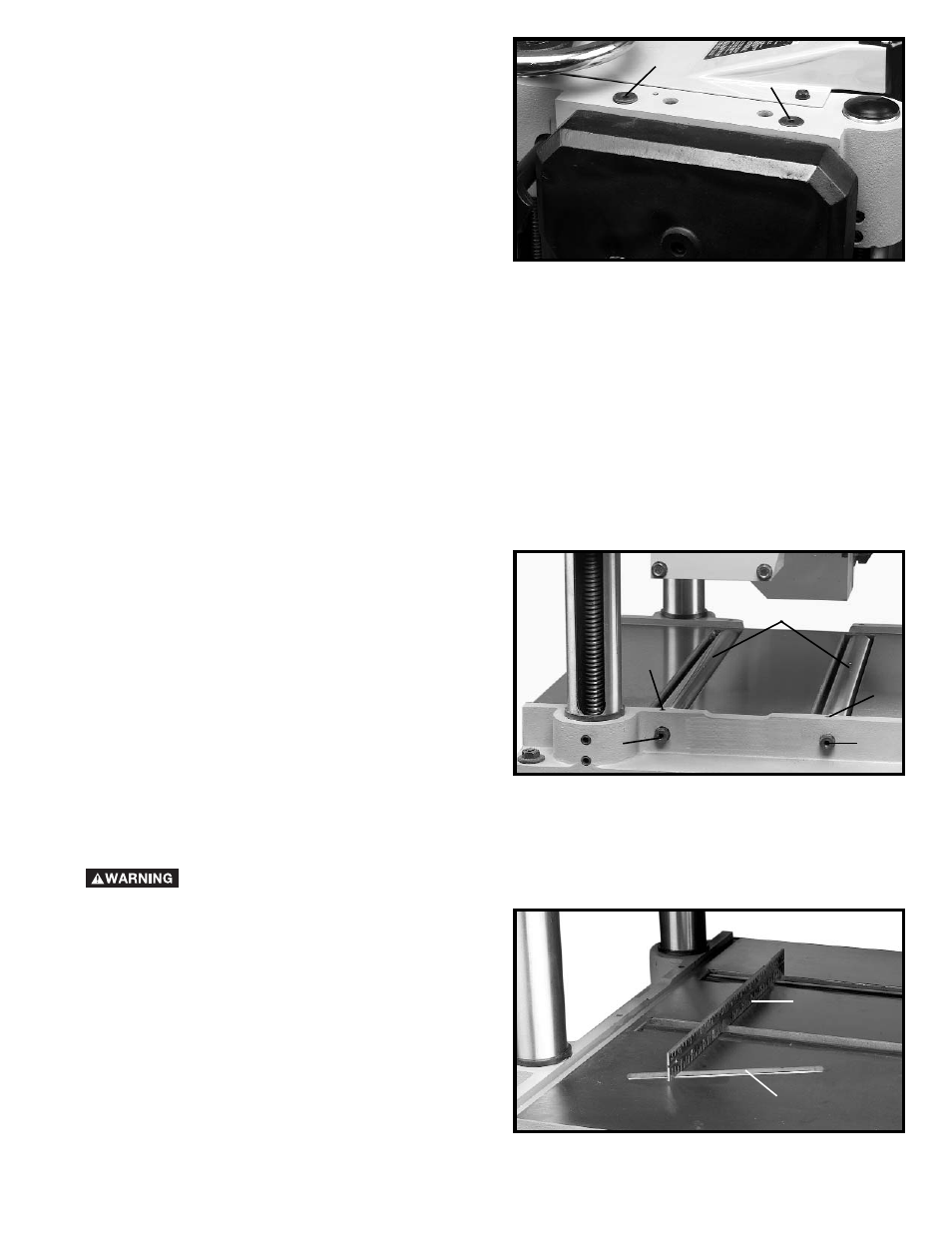

ADJUSTING TABLE ROLLERS

Your planer is supplied with two table rollers (A) Fig. 47,

which aid in feeding the stock by reducing friction and

turn as the stock is fed through the planer. It is not

possible to give exact dimensions on the proper height

setting of the table rollers because each type of wood

behaves differently. As a general rule, however, when

planing rough stock the table rollers should be set HIGH

(0.003" to 0.005") above the table surface and when

planing finish stock the table rollers should be set LOW,

0.001" above the table surface or level with the table

surface.

The table rollers on your planer are set for average

planing and are parallel to the table surface. If you desire

to adjust the table rollers higher or lower, proceed as

follows:

DISCONNECT MACHINE FROM POWER

SOURCE.

Lay a straight edge (B) Fig. 48, across both rollers and

with a feeler gage (C) underneath the straight edge as

shown, adjust height of table rollers by loosening set

screws (D) Fig. 47, and turn screws (E) to raise or lower

table rollers (A). Table rollers must be adjusted on the

opposite side of table in the same manner. The table

rollers must always be set parallel to the table.

IMPORTANT: The adjustment screws (E) Fig. 47, on

both sides of the planer are on eccentrics and care

should be taken when adjusting to keep the rollers

from leading the stock to one side or the other. This

can be accomplished by turning screws (E) Fig. 47,

clockwise to raise or lower the rollers and turning

the two screws on the opposite end of the rollers

counterclockwise or vice versa.

A

B

A

D

D

E

E

B

C