Electrolux EKM 90410 X User Manual

Page 7

7

E 14

25 W - 230 V~

T300°C

A

GB

IMPORTANT

The wires in the mains

cable

are coloured

as follows

:

GREEN AND YELLOW........EARTH

BLUE....................................NEUTRAL

BROWN ...............................LIVE

REPLACING

OF THE CABLE

If

the cable

becomes

damaged

or worn

, replace it,

observing

the

following instructions:

- open the box of the supply board as

shown

in

the

diagram

below;

- unscrew screw “A”

that secures

the cable;

- replace the cable with one of the same

length

and

which corresponds

to

the features described

in

the table; switch the appliance off, and

shut

the gas tap;

-

connect

the ‘green-yellow” earth wire to the terminal “ “, leaving

it approximately

10 mm longer

than

the live

wire

;

-

connect

the “blue” neutral wire

to the terminal marked “N”

;

-

connect

the live wire

to the terminal marked “L”

.

Always isolate the cooker from the electricity supply,

shut

off the gas

supply temporarily and proceed as follows.

- change the injectors,

- adjust the minimum flow of the burners.

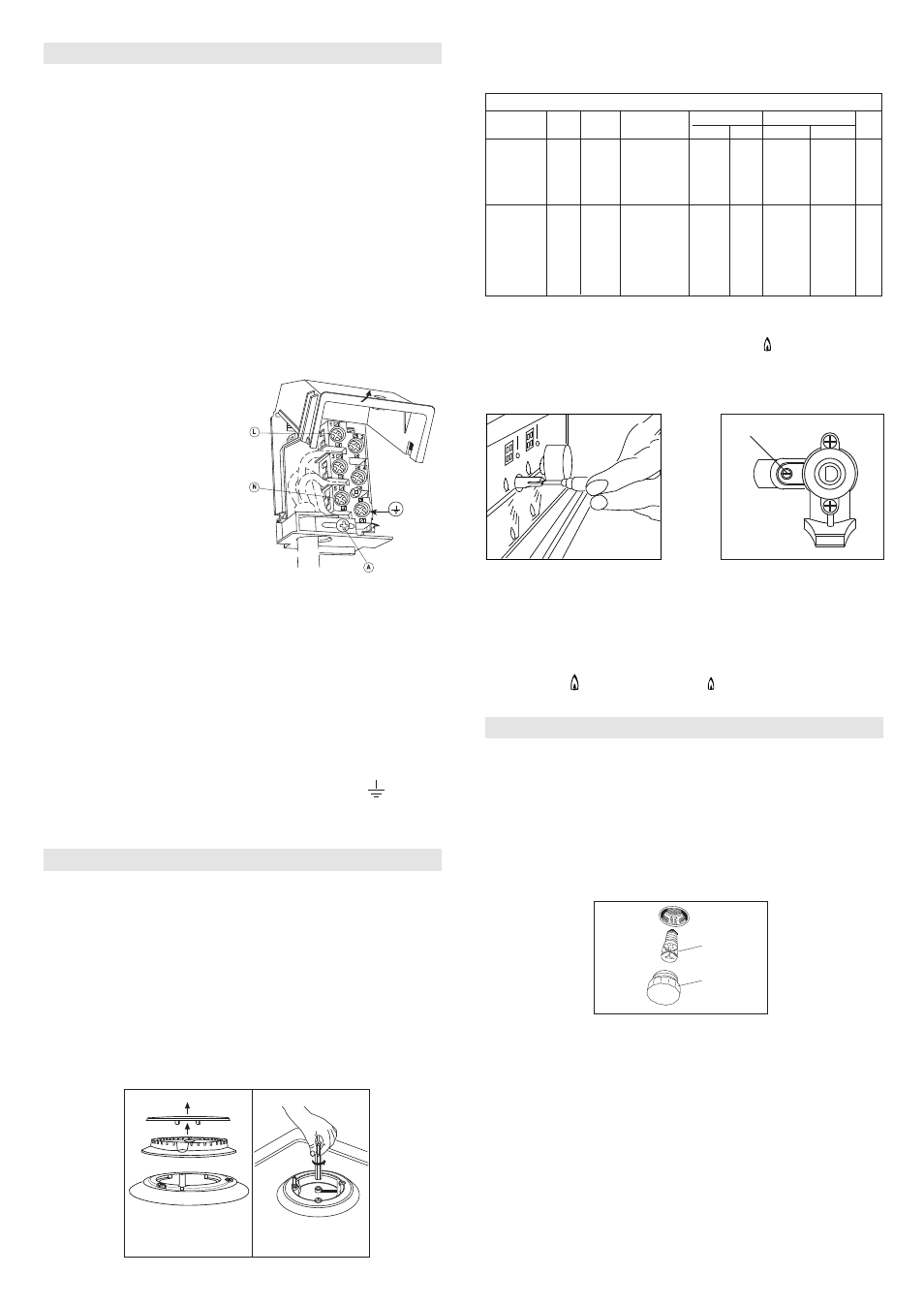

REPLACEMENT OF

COOKTOP

INJECTORS

To change

the

cooktop

injectors,

proceed

as follows: remove the

grids, remove burners and flame-spreaders (see fig.A), change the

injector (see fig.B) and replace it with another one suitable for the

new type of gas (see table D). Re-assemble everything in

reverse

order

,

ensuring you position

the flame-spreader

correctly

.

This appliance must be installed by a qualified person in

accordance with the

latest IEE

Regulations and in compliance

with the

manufacturer’s

instructions.

Check

that the voltage is the same as that stated on the rating plate.

The rating plate

is located

on the back cover.

WARNING! THIS APPLIANCE MUST BE EARTHED

If an fixed appliance is not equipped with supply cable and plug, the

power supply must be fitted with a disconnect switch in which the

distance between contacts permits total disconnection in accordance

with overvoltage category III, as required by installation regulations.

We recommend that the cooker circuit is rated to 13 amps.

Cable type HO5 RRF 3 X 1.5 mm

2

Connecting the mains cable

Open the mains terminal block cover as shown, unscrew screw “A”

the cable clamp

,

and

loosen

the screws in the mains terminal block

“L N E” which secure the three

wires of the mains cable. Fit the

cable and refit screw “A”

,

the cable

clamp.

Allow sufficient cable length for the

cooker to be pulled out for cleaning,

but do not let it hang

lower

than

50mm (2”)

from

the floor. The cable

can be looped if necessary, but

make sure that it is not kinked or

trapped when the cooker is in

position.

A

B

Fig. 11

MINIMUM FLOW ADJUSTMENT FOR

COOK

TOP TAPS

To adjust the minimum,

proceed

as follows: switch the burner on, and

turn the knob towards the minimum flow position

.

Remove the knob

from the tap, introduce a

small

screwdriver in

to

the tap rod (fig. 11).

Attention: in taps with security valve, the minimum

adjustment

screw

“Z” is placed outside the

tap

rod (fig. 12).

WARNINGS

Isolate the cooker from the electricity supply before attempting to

replace the oven lamp.

The oven lamp

is of a special type

designed to

withstand high

temperatures. To replace it,

proceed

as follows:

remove

the protect

ive

glass (A) and replace the burn

t-out

bulb

with one of the same type.

Re

-fit

the protecti

ve

glass.

DISMANTLING THE COOKTOP

If it

becomes

necessary to repair or replace

internal

components,

proceed

as follows: remove the glass lid from its position

by sliding

off upwards.

Remove the grids,

the

burners and flame-spreaders (see fig. 13),

unscrew the visible screws “V”

located

on the

cooktop

(see fig. 14).

Dismantle the cooktop

by unscrewing the 4 rear screws “A” (see fig.

15 ).

Loosen

the

adjustment

screw in order to increase the flow or

tighten

it to decrease the flow.

The proper adjustment is obtained when the flame is

approximately

3 or 4 mm

in length

.

For butane/propane gas, the

adjustment

screw must be

fully

screwed

down

.

Make sure that the flame does not go out

when

passing quickly from

the max. flow

to the minimum flow .

Assemble the knob again.

Fig. 12

Z

Values referred to Hs - 15°C - 1013,25mbar

TAB. D

Cat. II 2H3+

TABELLA GENERALE INIETTORI

Kind of gas

mbar

Nozzle

Burners

Power

KW Consum

N° max. min. max. min.

115

Rapide

3,00 0,75 286 l/h 72 l/h reg.

NATURAL 20 97

Semi rapide

1,75 0,48 167 l/h 46 l/h reg.

G 20 72

Auxiliary

1,00 0,33 95 l/h 31 l/h reg.

128

Triple crown

3,30 1,30 315 l/h 124 l/h reg.

BUTANE 28-30 85

Rapide

3,00 0,75 219 g/h 55 g/h 42

G 30 65

Semi rapide

1,75 0,48 128 g/h 35 g/h 31

50

Auxiliary

1,00 0,33 73 g/h 24 g/h 27

PROPANE 37 93

Triple crown

3,30 1,30 241 g/h 95 g/h 60

G 31

N°

By pass

ELECTRICAL CONNECTION

GAS ADJUSTMENT

APPLIANCE MAINTENANCE