Edelbrock 1400 User Manual

Page 4

CHOKE ADJUSTMENT

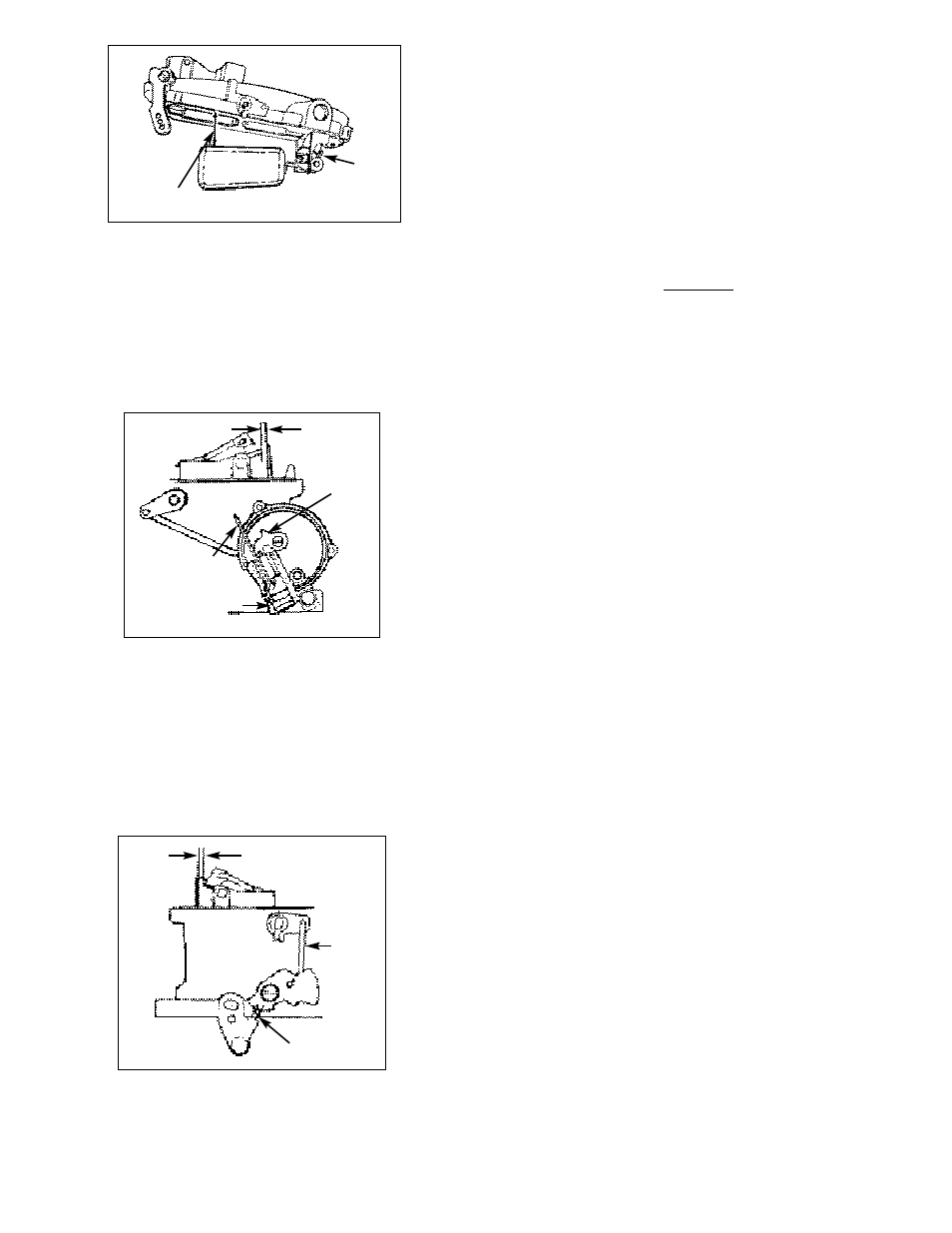

To adjust the choke piston linkage

(See Figure 5), open the choke valve and

insert a .026" wire, with a 90-degree bend 1/8" from the end, between the

top of the slot in the choke piston cylinder and the bottom of the slot in the

piston. Hold the wire in position and close the choke valve by pressing on

piston lever “A” until resistance is felt. The dimension “C” should be .100"

between the top edge of the choke valve and the air horn. To adjust, bend

rod “B”.

©2010 Edelbrock LLC

Brochure #63-0443

Part #1400

Rev. 6/10 - AJ/mc

Page 4 of 5

To adjust the fast idle linkage

(See Figure 6), place the fast idle screw A

between the two notches on the cam. Close the choke valve as far as

possible without forcing it. The dimension C should be 3/64" between the

choke valve and the air horn. To adjust, bend rod B. Fast idle may be

adjusted to manu-facturer’s specifications (usually 1500 rpm) during

normal choke cold operation. The fast idle screw A can be adjusted with

engine off and throttle held open to allow screw head access. Re-check

fast idle speed after each adjustment.

C (3/64")

B

A

Fig. 6

Slot (Piston)

.026" Wire

C (.100")

A

B

Fig. 5

Tab

Float Drop (1-1/4 ± 1/4")

Fig. 4

The length of time during which the choke will stay closed is determined

by the position of the choke cap. As the choke cap is turned clockwise,

the choke will stay closed longer. To properly set the choke, turn the

choke cap to the leanest notch on the choke housing, tighten the choke

housing retaining screws, and run the engine until normal operating

temperature is reached. With the engine running, slowly turn the choke

cap clockwise until the choke valve begins to close. Now turn the choke

housing one notch counterclockwise (LEAN) and tighten the choke

housing retaining screws. Periodic re-adjustment of the choke will be

required as the temperature changes throughout the year. After each

adjustment, verify that the choke valve opens fully after the engine is

warm.

CAUTION!!!

Do not overtighten the small Power Piston Cover screws when

servicing metering rods. They should only be tightened to 12

to 17 inch/pounds. Excessive torque will weaken or snap off

the screw heads.

If this happens, they may fall into the

carburetor causing serious engine damage. If an inch/pound

torque wrench is not available, snug the screw until it just

touches the plate, then tighten 1/16th turn more.

C.E.C. FUNCTION

Vehicles equipped with C.E.C. solenoids will require the use of

Edelbrock’s Idle Compensator Solenoid. Use part #8059. The

factory C.E.C. solenoid will not fit our throttle lever. However,

the Edelbrock Idle Compensator Solenoid will allow you to retain

the C.E.C. function and to pass visual emissions inspection in

California.

Remove front driver’s side carb stud and replace with longer stud

supplied in this kit. Place bracket over the stud and install nut and

washer on stud. Position solenoid in bracket and install large washer

(locking tabs face the solenoid) and locknut. Tighten firmly, but be

careful not to over-tighten due to the large size (1-1/4") of the wrench

used. Bend locking tabs on special washer over flats of the nut to

prevent loosening. Attach the wire from the solenoid to the existing

C.E.C. wiring connector.

If the factory connector does not fit, you will need to splice into the wire

from the connector. Use a 1/4" female receptacle and at least 18-20

gauge wire. Some receptacles will require that the locking tab on the

solenoid be flattened before the receptacle will fit.

ADJUSTMENT

With the Idle Compensator Solenoid disconnected, adjust the Idle

Speed Screw until you reach the desired idle RPM.

With the Idle Compensator Solenoid connected and the ignition in

the “On” position, adjust the solenoid until it just contacts the

throttle lever. Next, start the engine and turn the Idle Speed Screw

counter-clockwise to make sure the idle speed is maintained by the

solenoid. If necessary, adjust idle speed by turning solenoid plunger

in or out with a 1/2" wrench. Shut off the engine.

Turn the Idle Speed Screw counter-clockwise until the throttle lever

is completely closed and the Idle Speed Screw is not touching the

throttle lever. Turn the Idle Speed Scruew clockwise until it just

makes contact with the throttle lever. Continue turing 1/4 turn

more. This will make sure the throttle blades will not bind in the

bore when the solenoid is turned off.