2 purpose of the heat pump, 1 application, 2 operating principle – Dimplex LI 11MER User Manual

Page 4: 3 scope of delivery, 1 basic device, Attention

www.dimplex.de

E-3

English

3.1

2 Purpose of the Heat

Pump

2.1

Application

The air-to-water heat pump is designed for use in existing or

newly built heating systems.

It is designed exclusively for heating and cooling heating water!

In heating operation, the heat pump is suitable for mono energy

and bivalent operation down to an external temperature of

-20 °C.

Proper defrosting of the evaporator is guaranteed by maintaining

a heating water return flow temperature of more than 18 °C dur-

ing continuous operation.

The heat pump is not designed for the increased heat consump-

tion required when a building is being dried out. The additional

heat consumption should be met using special devices provided

by the customer. If a building is to be dried out in autumn or win-

ter, we recommend installing an additional heating element

(available as an accessory).

In cooling operation the heat pump is suitable for temperatures

ranging from +15 °C to +40 °C.

It can be used for silent and dynamic cooling. The minimum

water temperature is +7 °C.

ATTENTION!

The device is not suitable for operation with a frequency converter.

2.2

Operating Principle

Heating

Surrounding air is drawn in by the ventilator and fed via the evap-

orator (heat exchanger). The evaporator cools the air, i.e. it ex-

tracts heat from it. This extracted heat is then transferred to the

working medium (refrigerant) in the evaporator.

The heat is “pumped” to a higher temperature level by increasing

its pressure with the aid of an electrically driven compressor. It is

then transferred to the heating water using the liquifier (heat ex-

changer).

Electrical energy is used to raise the temperature of the heat in

the environment to a higher level. Because the energy extracted

from the air is transferred to the heating water, this type of device

is called an air-to-water heat pump.

The air-to-water heat pump consists of the main components

evaporator, ventilator and expansion valve, as well as the low-

noise compressor, liquifier and electrical control system.

At low ambient temperatures, humidity accumulates on the evap-

orator in the form of frost reducing the transfer of heat. The evap-

orator is defrosted automatically by the heat pump as required.

Steam may be emitted from the air outlet depending on the at-

mospheric conditions.

Cooling

The functions of the evaporator and the liquifier are reversed in

the “Cooling” operating mode.

The heating water transfers its heat to the refrigerant via the liq-

uifier which is now functioning as an evaporator. The refrigerant

is pumped to a higher temperature level using the compressor.

Heat is passed on to the surrounding air via the liquifier (function-

ing as an evaporator in heating operation).

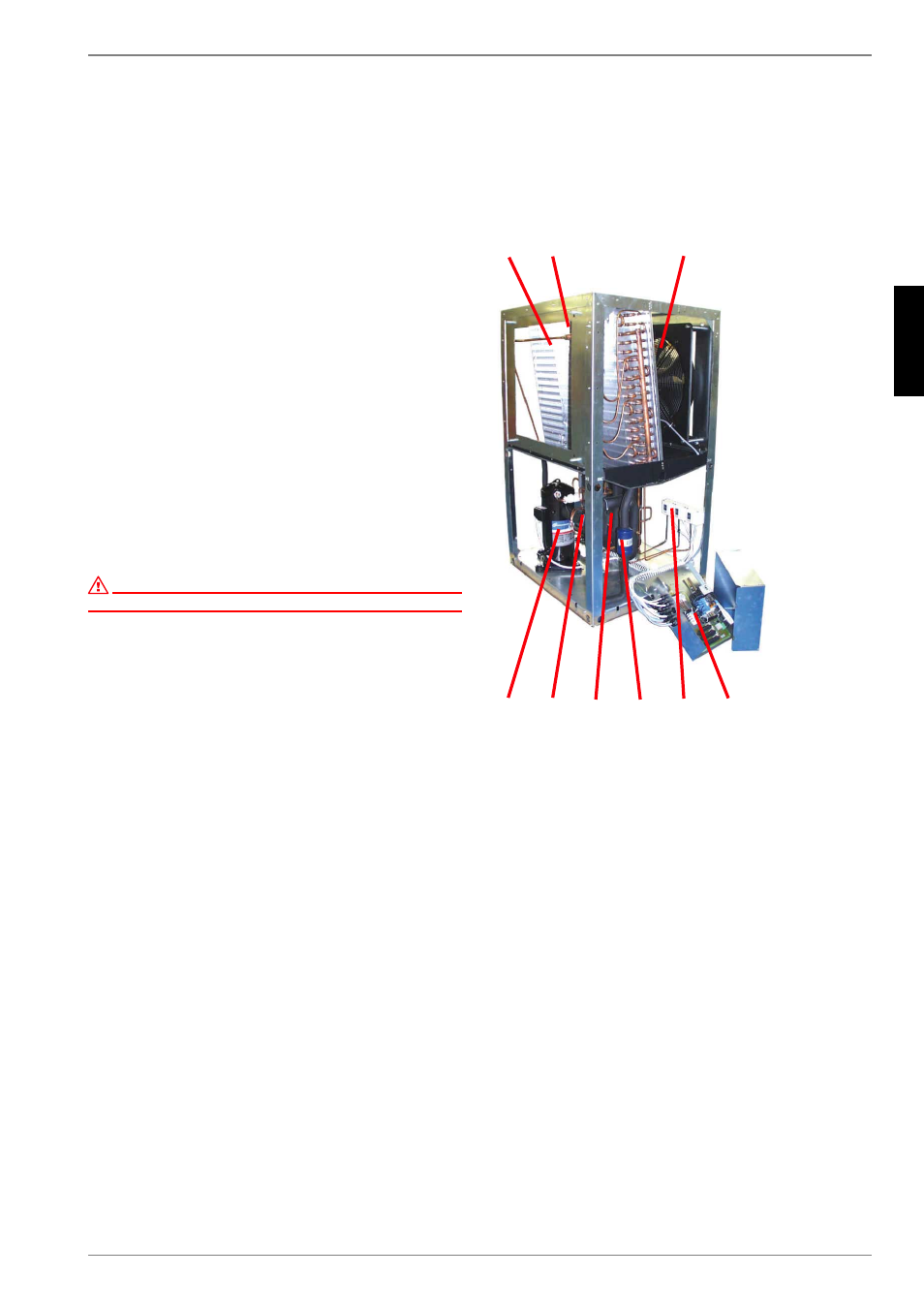

3 Scope of Delivery

3.1

Basic Device

The heat pump is of compact design and is supplied complete

with the components listed below.

R404A is used as the refrigerant.

1)

Evaporator (heating operation)

2)

Check valve

3)

Ventilator

4)

Switch box

5)

Pressure switches

6)

Filter dryer

7)

Liquifier (heating operation)

8)

Expansion valve

9)

Compressor