Ni-mh rechargeable batteries, Battery construction (cont.), 3 prismatic cell construction – Duracell Ni-MH User Manual

Page 6

Ni-MH Rechargeable Batteries

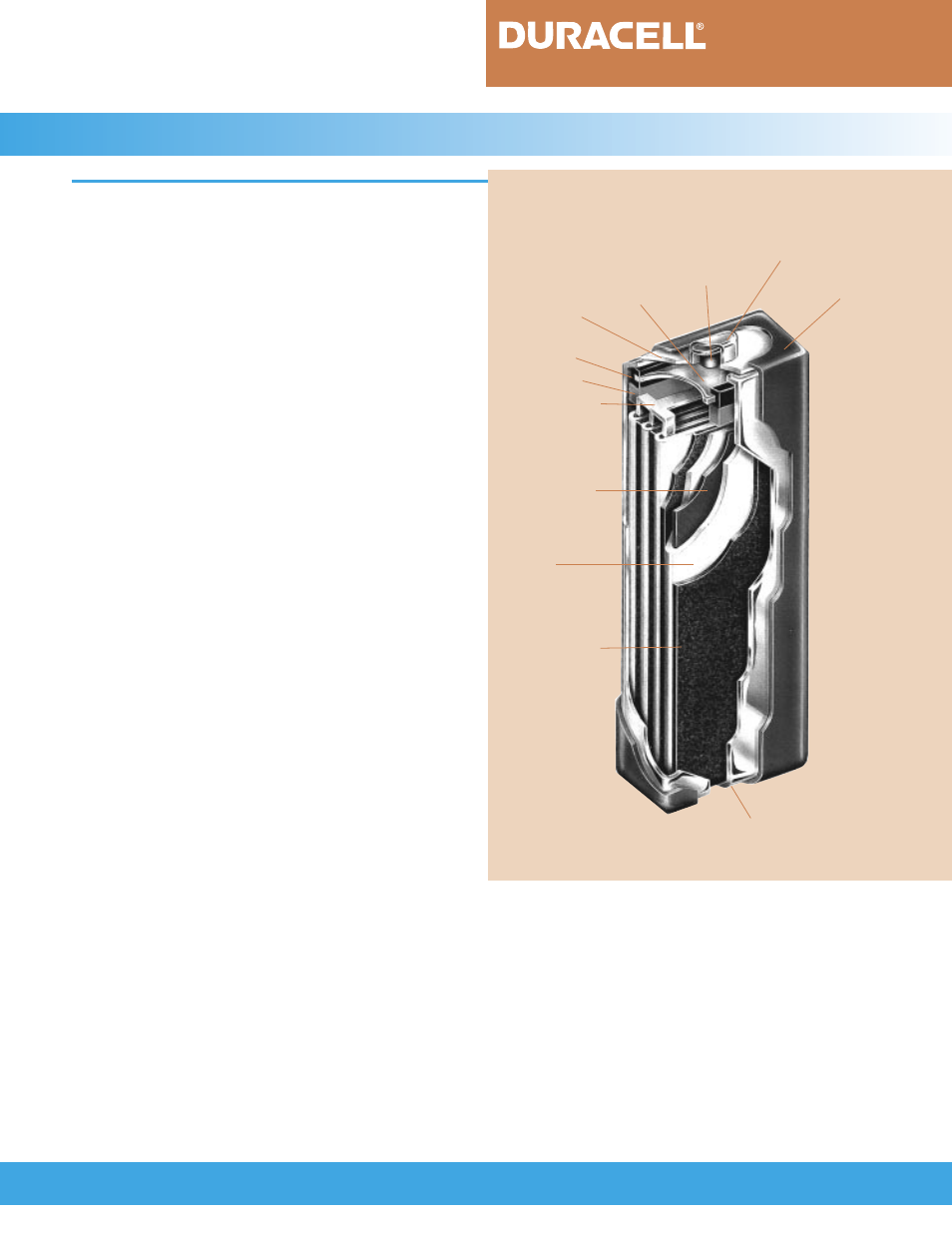

The basic differences between the prismatic

cell and the cylindrical cell are the construction of

the electrodes and the shape of the can. Prismatic

cells are designed to meet the needs of compact

equipment where space for the battery is limited.

The rectangular shape of the prismatic cell permits

more efficient battery assembly by eliminating the

voids that occur in a battery constructed with

cylindrical cells. Thus, the

volumetric energy density

of a battery can be increased by constructing it with

prismatic instead of cylindrical cells.

Figure 4.3.1 shows the structure of the pris-

matic nickel-metal hydride cell. The electrodes are

manufactured in a manner similar to those of the

cylindrical cell, except that the finished electrodes are

flat and rectangular in shape. The positive and

negative electrodes are interspaced by separator

sheets. The assembly is then placed in a nickel-plated

steel can and the electrolyte is added. The positive

electrodes are connected to the metal lid with a tab.

The cell is then sealed by crimping the top assembly to

the can. The top assembly incorporates a resealable

safety vent, a metal lid and a plastic gasket that is

similar to the one used in the cylindrical cell. A heat-

shrink tube is placed over the metal can. The bottom

of the metal can serves as the negative terminal and

the top metal lid as the positive terminal. The insula-

tor and gasket insulate the terminals from each

other. The vent provides additional safety by re-

leasing any excess pressure that may build up if the

battery is subjected to abusive conditions.

4.3 Prismatic Cell Construction

FIGURE 4.3.1

5

Battery Construction (cont.)

Metal Lid

Gasket

Insulator

Positive Tab

Cosmetic

Disk

Safety Vent

Positive Electrode

Negative Electrode

(-) Negative Terminal

Separator

(+) Positive Terminal

Heat Shrink Tube