Vortech 1999-2001 Ford 5.4L/6.8L Super Duty/SUV User Manual

Page 15

P/N: 4FT020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

02AUG04 v2.1(99-03SuperDuty(4FT v2.1))

3

H. Install the harmonic balancer puller. Evenly start

the three puller screws (M10 x 1.5). Engage the

forcing screw against the pivot and check align-

ment.

I. After ensuring the puller is properly aligned on

the face of the crank, slowly tighten the forcing

screw until the harmonic balancer has been

removed.

J. With a small amount of silicone on the keyway of

the new harmonic balancer, guide it on the

crankshaft and feel for alignment of the wood-

ruff key and the harmonic balancer keyway.

After the harmonic balancer has been aligned

on the crankshaft, use your harmonic balancer

installation tool to install the new harmonic bal-

ancer. Slowly tighten until the harmonic bal-

ancer is seated on the crankshaft.

2.

HARMONIC BALANCER AND CRANK PULLEY INSTALLATION, cont’d.

NOTE:

When using the harmonic balancer puller, pay special atten-

tion to alignment of the forcing screw and pivot. Improper

alignment can result in crankshaft damage.

NOTE: The factory uses a small amount of silicone to seal the crank-

shaft keyway. Thoroughly clean the silicone and any oil resi-

due off of the crankshaft prior to installing the Vortech har-

monic balancer.

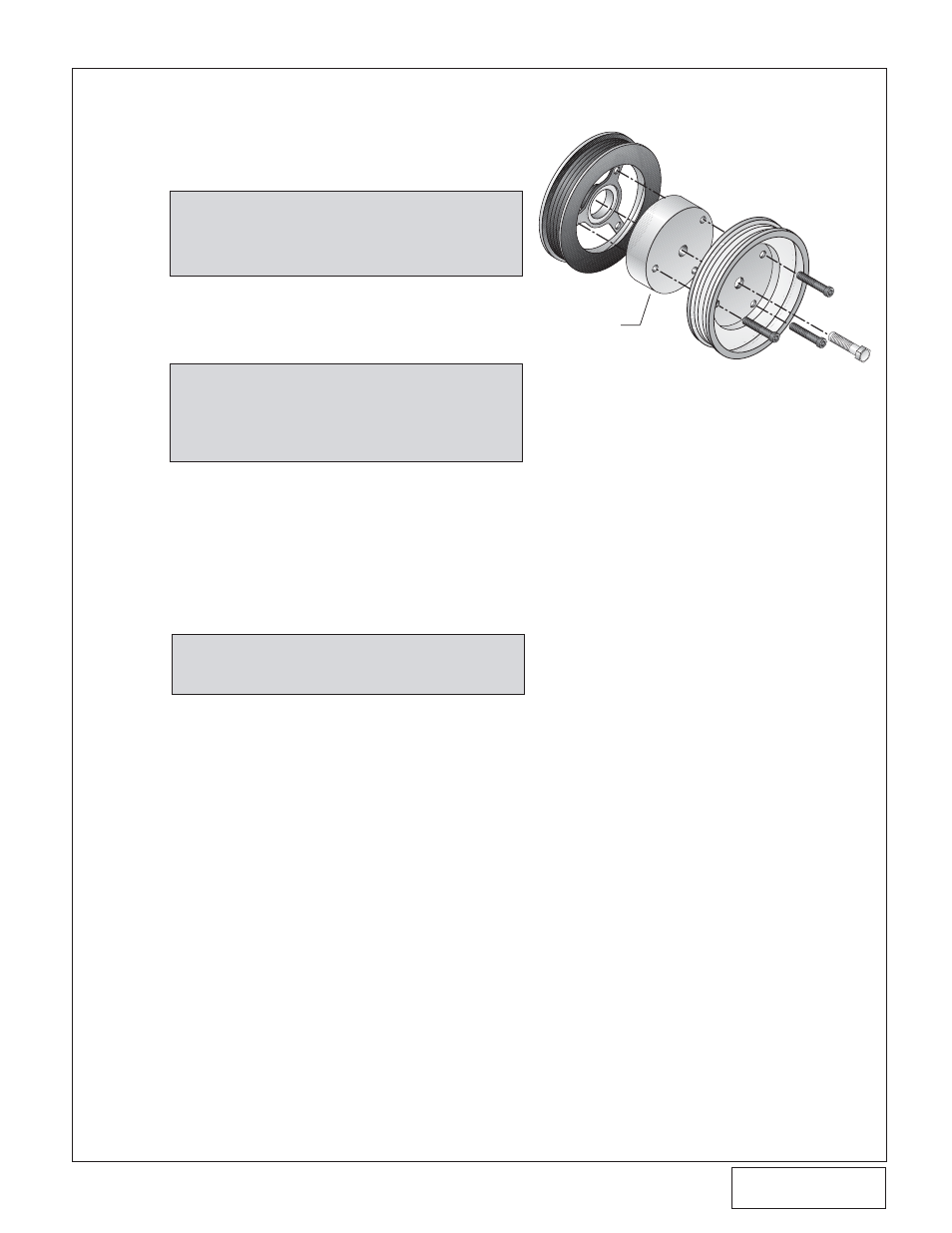

K. Remove the installation tool and place the su-

percharger drive pulley and spacer on the front

of the harmonic balancer. (See

Fig. 2-a.) Feel-

ing for alignment, start the supplied M12 x 1.5 x

65mm center screw and rotate the supercharger

drive pulley until the three screw holes are

aligned. Start the three M10 x 1.5 x 40mm cap

screws with washers, evenly tighten all begin-

ning with the center screw. Torque the M12

screw to 80 ft/lbs and the M10 screws to 25 ft/

lbs.

L. Reinstall the rubber inspection plug (if previ-

ously removed) and the accessory drive belt.

Do not reinstall the fan and fan shroud at this

time.

NOTE:

The use of Loctite blue is recommended for all harmonic

balancer and crank pulley screws.

Fig. 2-a

SPACER