Chuck key – Delta 70-200 User Manual

Page 9

9

Fig. 11

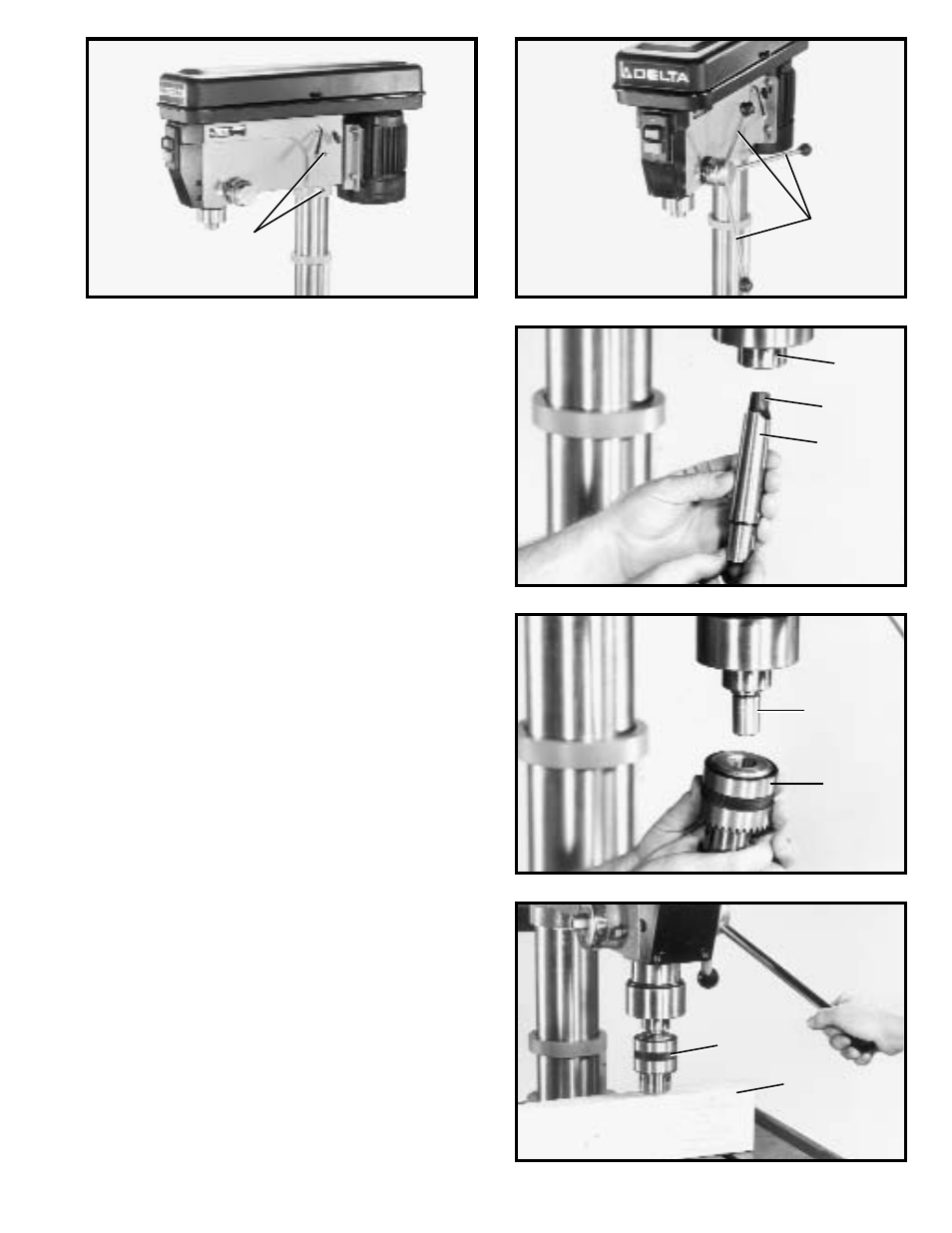

11. Place the drill press head on column, as shown. Line

up head with base and tighten two head locking screws

(R) Fig. 11.

12. Thread the three pinion wheel handles (Z) Fig. 12,

into the three threaded holes in the pinion shaft, as

shown.

13. Make certain the tapered hole in the bottom of the

spindle (T) Fig. 13, and the taper on the spindle adapter

(U) are clean and push the spindle adapter (U) up into

the spindle, making certain the tang (V) engages and

locks with the mating slot inside the spindle.

Fig. 12

Fig. 13

Fig. 14

Fig. 15

14. Make certain the bottom taper of the spindle

adapter (U) Fig. 14, and the tapered hole in the chuck

(W) are clean and push the chuck up onto the spindle

adapter (U) as far as it will go. NOTE: Household oven

cleaner can effectively remove any substance from the

spindle and chuck; however, carefully follow the manu-

facturer’s safety rules concerning its use.

15. Open the chuck jaws as wide as possible by turning

the chuck sleeve (X) Fig. 15.

16. Place a block of wood (Y) Fig. 15, on the drill press

table and lower the spindle until the chuck contacts the

piece of wood. Exert pressure to properly seat the

chuck.

CHUCK KEY

This drill press is provided with a self-ejecting type

chuck key. Use only this key or a duplicate. The use of

the self-ejecting chuck key ensures that the chuck key is

removed before the chuck is rotated.

R

Z

T

V

U

U

W

X

Y