TFC Group TMV User Manual

Page 4

Thermostatic mixing valves

TFC GROUP LLP Tower House, Vale Rise, Tonbridge, Kent TN9 1TB

Tel: 01732 351680 Email: [email protected] Web: www.tfc-group.co.uk

IN-SERVICE TESTING

The purpose of in-service testing is to regularly monitor the thermal performance of the

thermostatic mixing valve. Deterioration in performance can indicate the need for service work

to be carried out on the system.

If the authority concerned does not have a planned test and maintenance schedule then the

suggestions below should form the basis of a new system.

At intervals of 6-8 weeks and 12-15 weeks after commissioning:

a. Check supply parameters are still within the expected values if not check system for faults.

b. Carry out commissioning procedures 1) to 6) using the same test equipment, if the mixed

water temperature has changed a significant amount (by more than 1K) check to ensure

in-line filters are clean, that the check valves are working and all isolating valves are fully

open. If no fault can be found check and record the mixed water temperatures and

re-adjust mixed water temperature to the values in table 2.Complete the commissioning

procedure 1) to 6) if the mixed water temperature exceeds the values of the maximum

recorded temperature by more than 2K the need for service work is indicated.

Depending on the results of these two tests the following should be adopted.

I. If a small change (e.g.1K to 2K) occurs in one of these tests or there is no significant change

(e.g.1K maximum) then the next in service test should be 24 to 28 weeks after

commissioning.

II. If small changes occur in both test or a larger change occurs in one test (exceeding 2K) then

the next in service test should be carried out 18 to 21 weeks after commissioning.

These results can then be used to set a service interval which tests have shown can be used

with no more than a small change in mixed water temperature. This method of determining

service intervals is used to take into account various in-service conditions (i.e. water condition)

that the valve may experience.

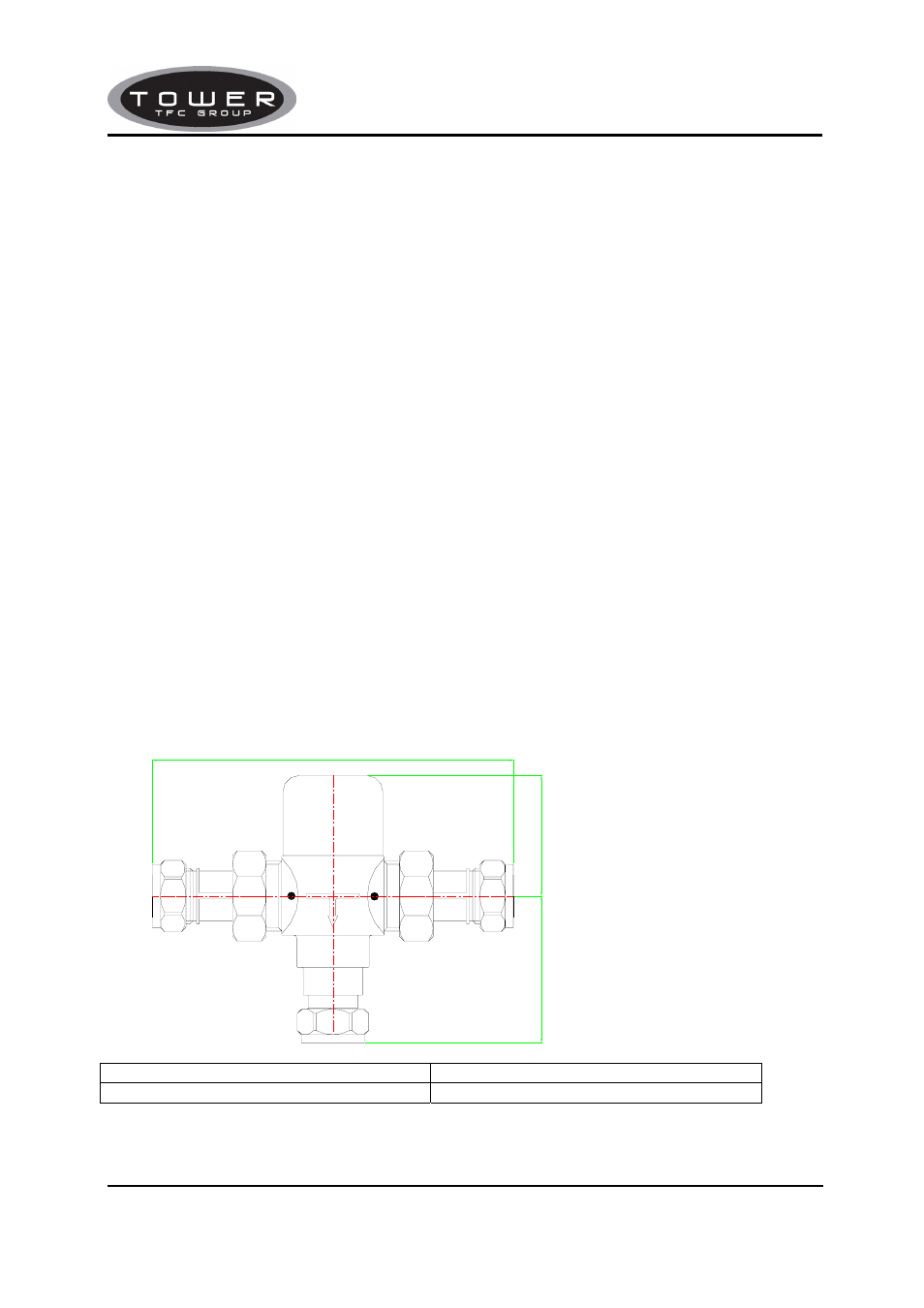

CONNECTIONS SPECIFICATIONS

H

C

134

56

44.

70

INLETS 15mm

Compression

OUTLET 15mm

Compression