Thermostatic mixing valves – TFC Group TMV User Manual

Page 2

Thermostatic mixing valves

TFC GROUP LLP Tower House, Vale Rise, Tonbridge, Kent TN9 1TB

Tel: 01732 351680 Email: [email protected] Web: www.tfc-group.co.uk

NOTE: ALL INSTALLATION AND MAINTENANCE PROCEDURES SHOULD

BE CARRIED OUT IN ACCORDANCE WITH THESE GUIDELINES.

PLEASE READ THESE GUIDELINES BEFORE COMMENCING ANY

NEW INSTALLATION OR SERVICING OF EXISTING UNITS.

INSTALLATION RECOMMENDATIONS

The following general recommendations should be observed.

1) Always install isolating valves to facilitate servicing.

2) Always flush both supply pipes fully before connecting mixing valve to ensure no pipe debris

enters the inlets. Always fit filters provided.

3) All installations must comply with current local water company regulations.

TO CLEAN

1. Soak all metal parts in de-scaler, wash off in clean water.

2. Lightly grease all metal parts with silicone grease.

3. Replace worn and damaged ‘O’ rings.

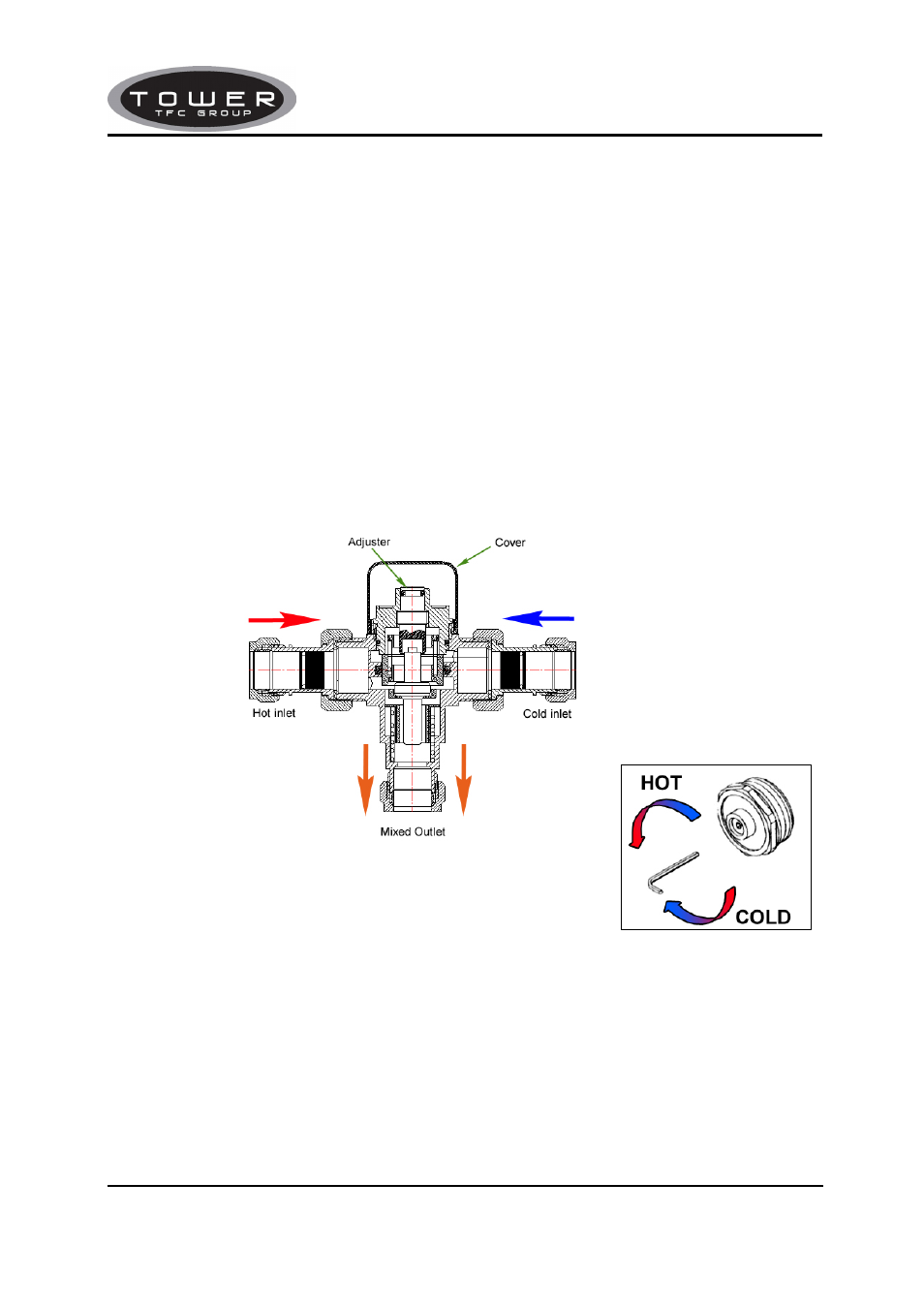

TEMPERATURE SETTING

1. Turn adjustment screw clockwise for cooler temperature,

Anti-clockwise for warmer temperature. Replace head cover.

CONDITIONS FOR NORMAL USE

In order to give compliance with N.H.S. specification D08 and TMV2 scheme, the table below lists

the conditions for normal use, the valves may perform adequately outside these parameters but the

scope of the TMV2 and TMV3 scheme does not apply. If they are required to work with other supply

conditions an engineer must carry out a risk assessment and satisfy themselves that the units are

still suitable for use.