Appendix e: error codes & troubleshooting, Sensor replacement requires calibration gas – Test Products International 712 User Manual

Page 33

Appendix E: ERROR CODES & TROUBLESHOOTING

The 712 analyzer will display certain codes to let you know of a malfunction.

*Sensor replacement requires calibration gas.

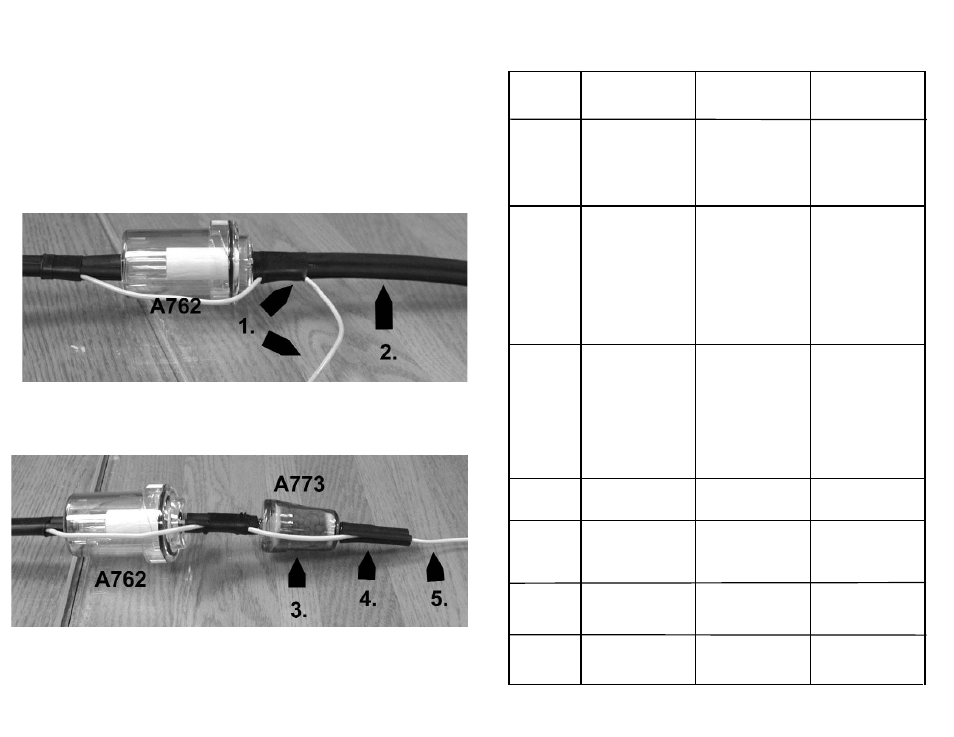

Appendix D: INSTALLING THE OPTIONAL A773 OIL FILTER

When performing combustion tests on oil fired equipment it is important to use

the optional A773 oil filter to ensure stable readings. The A773 does not have to

be removed when working with other types of fuels.

PROCEDURE

1. Pull the yellow thermocouple out of the cord channel in the tubing up to the

cord stop.

2. Cut the tubing approximately 1 1/2 inches from the end of the A762 water trap / fil-

ter assembly.

3. Insert the A773 oil filter into the tube below the A762.

4. Cut the remaining piece of tube into a 1 1/2 inch piece and connect it onto the end

of the A773 oil filter.

5.. Press the thermocouple cord into the cord channel.

The A773 should be replaced when most of the pellets become discolored.

Code

Displayed

Code Definition

Possible Causes

Corrective Action

Flo

Err

Pump not drawing sample at

correct flow rate.

Blockage / kink in flue probe

hose.

Dirty or blocked filter(s).

Worn pump.

Check and rectify.

Replace filter(s).

Return to TPI for service.

InIt

O2

Err

Oxygen sensor failed to ini-

tialize

Flue probe connected to 712

prior to power up.

712 did not purge completely

from last sample.

Worn or defective oxygen

sensor.

Disconnect probe and

restart.

Purge for 20 minutes and

restart.

Return to TPI for sensor

replacement or install new

sensor.*

Try manually initializing the

sensor. See Appendix G.

InIt

CO

Err

Carbon monoxide sensor

failed to initialize.

Flue probe connected to 712

prior to power up.

712 did not purge completely

from last sample.

Worn or defective carbon

monoxide sensor.

Disconnect probe and

restart.

Purge for 20 minutes and

restart.

Return to TPI for sensor

replacement or install new

sensor.*

Try manually initializing the

sensor. See Appendix G.

Lo

bat

Low battery.

Battery needs to be charged. Charge battery. If the battery

won’t hold a charge, replace

the battery.

oFL

Overflow indication. The

pressure being measured is

outside the maximum mea-

surement capability.

Pressure being measured is

too high or low.

Pressure sensor damaged or

defective.

Remove pressure source.

Return to TPI for service.

oFL

Overflow indication. The tem-

perature being measured is

outside the maximum mea-

surement capability.

Temperature being measured

is too high or low.

Remove pressure source.

oPEn

Unable to read thermocouple

(temperature).

Temperature probe not con-

nected to input.

Worn temperature sensor.

Connect temperature probe

to analyzer.

Replace temperature probe

or flue probe.