Adjusting spindle return spring, Operations – Delta 17-900 User Manual

Page 13

13

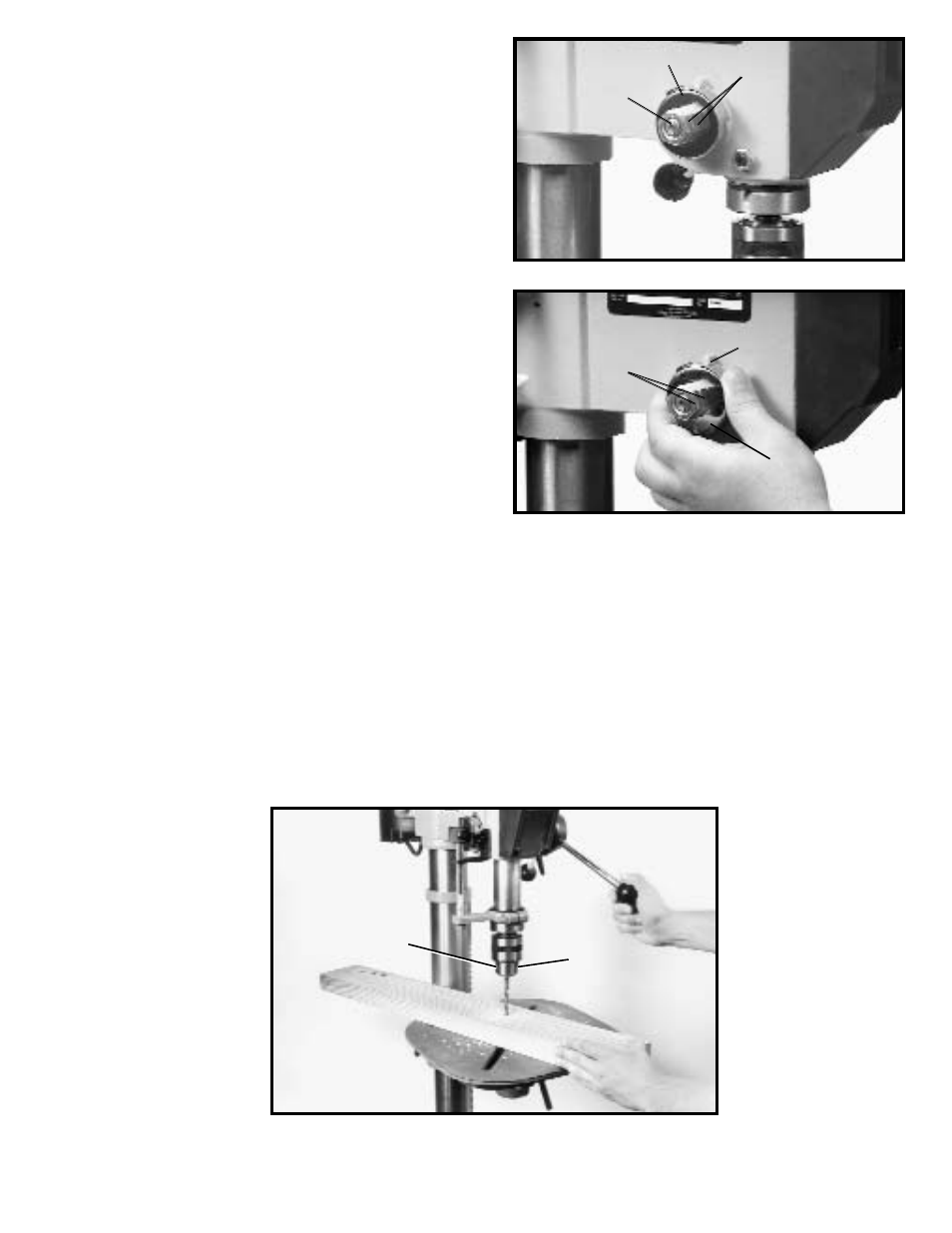

Fig. 27

Fig. 28

ADJUSTING SPINDLE

RETURN SPRING

The spindle is automatically returned to its upper most

position upon release of the handle. It is recommended

that the handle be allowed to slowly return to the top

position after all holes have been drilled in the material.

This spring has been properly adjusted at the factory

and should not be disturbed unless absolutely

necessary. To adjust the return spring, proceed as

follows:

1.

Disconnect the tool from the power source.

2.

Loosen the two nuts (B) Fig. 27, approximately 1/4”.

Do not remove nuts (B) from shaft (C).

3.

While firmly holding spring housing (A) Fig. 28, pull

out housing and rotate it until the boss (D) is engaged

with the next notch on the housing. Turn the housing

counter-clockwise to increase and clockwise to de-

crease spring tension. Then tighten the two nuts (B) to

hold the housing in place. IMPORTANT: Inside nut (B)

should not contact spring housing (A) when tight.

B

C

A

D

A

B

OPERATIONS

Your Drill Press should be used with drill bits that have shank diameters of 5/8" or less.

The following directions will give the inexperienced operator a start on common drill press operations. Use scrap

material for practice to get a feel of the machine before attempting regular work. IMPORTANT: After installing a drill

bit into the chuck, always tighten the jaws of the chuck using the key supplied in all three locations of the chuck,

two of which are shown at (E) Fig. 30.

IMPORTANT: When the workpiece is long enough, it should always be positioned on the table with one end against

the column, as shown in Fig. 30. This prevents the workpiece from rotating with the drill bit or cutting tool, causing

damage to the workpiece or personal injury to the operator. If it is not possible to support the workpiece against the

column, the workpiece should always be fastened to the table using clamps or a vise.

Fig. 30

E

E