Drilling holes to depth, Changing spindle speeds and adjusting belt tension – Delta 17-900 User Manual

Page 12

12

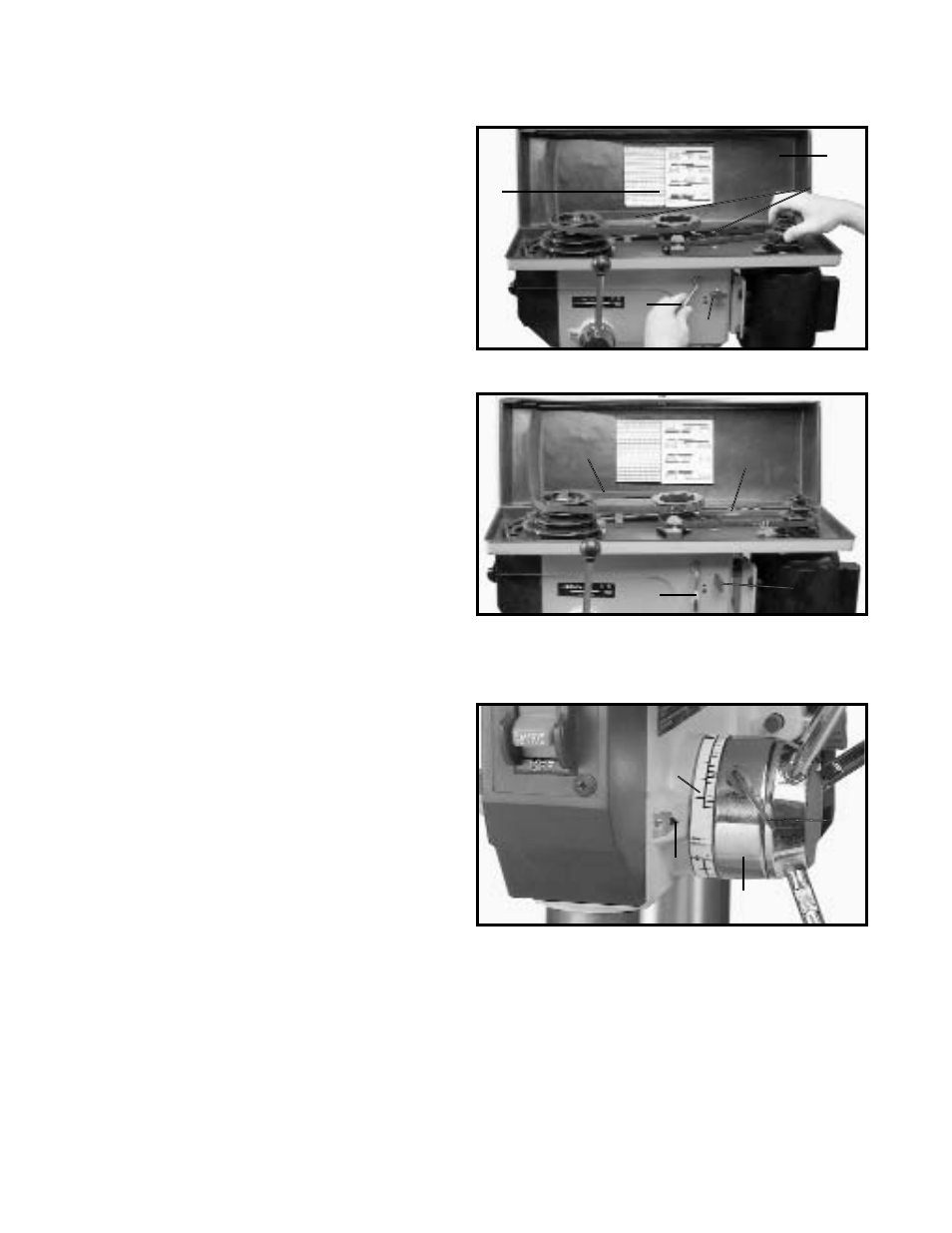

Fig. 26

DRILLING HOLES

TO DEPTH

When a number of holes are to be drilled to exactly the

same depth, a depth stop is provided in the pinion shaft

housing and is used as follows:

1.

Loosen lock screw (A) Fig. 26, and rotate housing (B)

until the pointer (C) lines up with the desired depth

indicated on scale (D). Then tighten lock screw (A).

2.

All holes will then be drilled to the exact depth as

indicated on scale (D) Fig. 26. NOTE: Scale (D) is

calibrated in both inches and millimeters.

Fig. 24

Fig. 25

CHANGING SPINDLE SPEEDS AND

ADJUSTING BELT TENSION

1.

DISCONNECT THE DRILL PRESS FROM THE

POWER SOURCE.

2.

Raise the belt and pulley guard (A) Fig. 24.

3.

Release tension on the belt by loosening lock knob

(B) Fig. 24, and the tension knob located on the other

side of the head casting and moving tension lever (C)

forward.

4.

Position both belts (D) Fig. 24, on the desired steps

of the spindle, center, and motor pulleys as shown.

Refer to chart (E) Fig. 24, which is conveniently located

on the underside of the belt and pulley guard (A) for belt

position and speed charts.

5.

After the belts are positioned on the desired steps of

the spindle, center, and motor pulleys, move tension

lever (C) Fig. 25, to the rear until the belts are properly

tensioned and tighten two tension lock knobs (B), one of

which is shown. NOTE: The belts should be just tight

enough to prevent slipping. Excessive tension will

reduce the life of the belt, pulleys, and bearings. Correct

tension is obtained when the belts (D) can be flexed

approximately one inch at the center of the pulleys using

light finger pressure.

A

C

B

E

D

C

B

D

D

A

B

C

D