Bottom drain valve model a177vb2 – Parr Instrument A177VB2 User Manual

Page 3

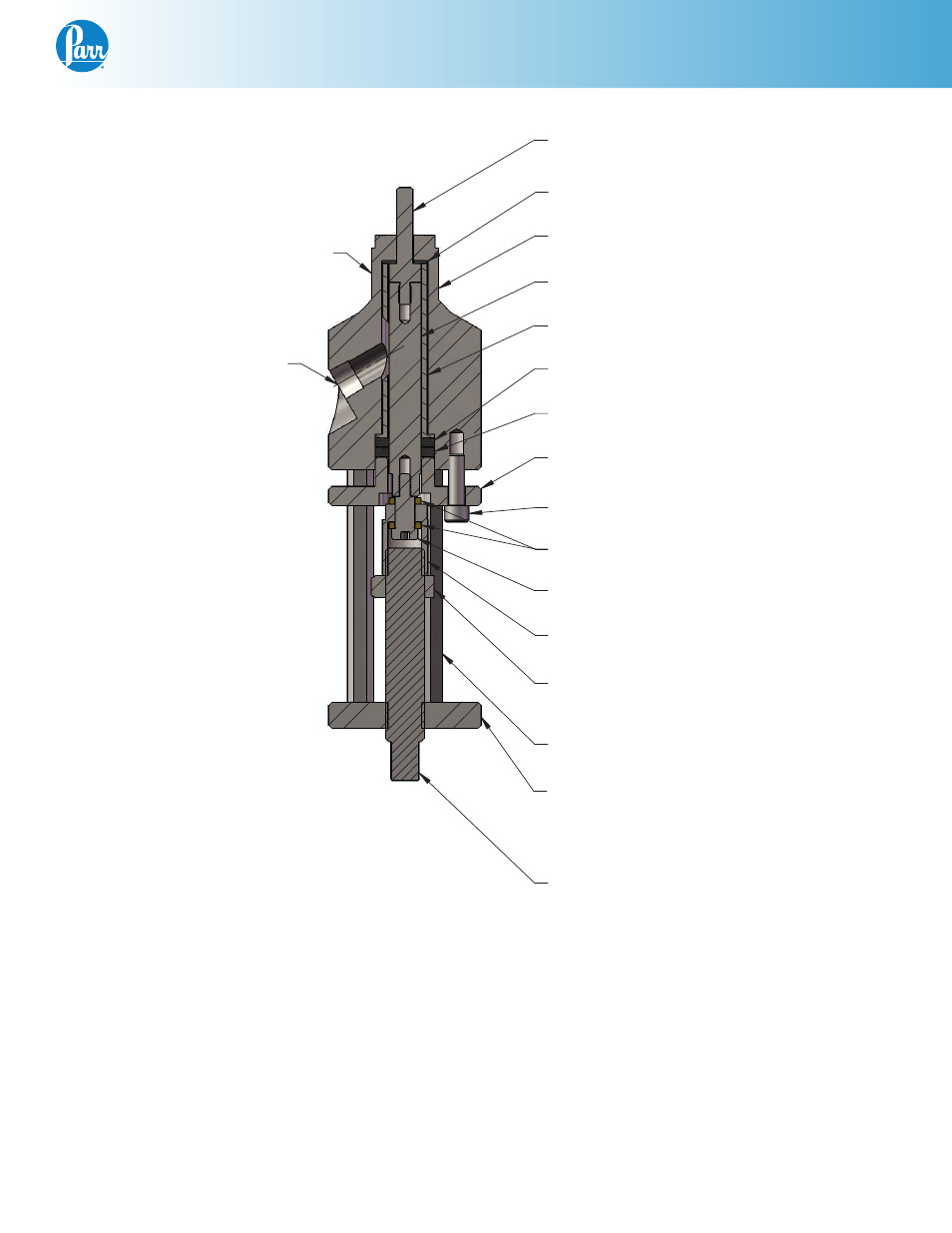

Bottom Drain Valve Model A177VB2

w w w . p a r r i n s t . c o m

3

Lubrication of the Bottom Drain Valve

Lubrication of the straight threads should be done

with a nickel based high temperature thread lu-

bricant. If SD2520SC10 shoulder bolt is removed,

re-install into plunger with semi-permanent thread

locker. Lubricate all other internal and outer straight

threads on the valve body, retainers, and plunger.

A177VB2

511VB5*

SEAL 1

1" NPS REF

692VBKL

SEAL 2 (FRONT)

SD2520SC10

1/4-28 X .375 SHSB

SEAL 2 (BACK)

5/16-18 X 3/4 FHSCS

3720HC

PLUNGER TIP

3723HC*

STANDOFF

3724HC*

VALVE BODY

3555HC

(3) TB3118FS12

(3) TB3118SC16

SCREW SHAFT

SCREW SHAFT

(3) 3719HC

RETAINER

JAM NUT

3/4-10

SLEEVE

3722HC*

5/16-18 X 1.00 SHCS

692VBHA

RETAINER

3721HC

PLUNGER BASE

3725HC*

RETAINING CAP

3556HC

3718HC

3554HC

SHIM

3/8 NPT

REF

*Available in other alloys

The frequency of lubrication depends on the amount

of use the valve receives. If the valve sits for a long

period of time (one or more months), it should be

lubricated before use. If the valve is used daily, then

lubrication may be required once a week.

Applications that include operating temperatures of

250°C and above will require more frequent lubrica-

tion of the valve threads.