Internal cooling loop, Liners, Spare parts kit – Parr Instrument Series 4580 User Manual

Page 18: Air motor, Accessories (continued)

- 17 -

ACCESSORIES (continued)

Internal Cooling Loop

A serpentine cooling coil is mounted to the

underside of the head and sealed with a ferrule

and compression nut arrangement.

A slow continuous flow of cold water

through the coil is an effective means for

controlling temperature overshoot, particularly

when operating at temperatures below 150

C.

Alternately the cooling coil is used to effectively

cool the system at the completion of a reaction.

An optional solenoid valve package is

available to automate the cooling process.

This package coordinates with the internal coil,

with the water supply and connects to the

temperature controller.

If the internal cooling is not required, the

coil may be removed and the alternate plugs

installed.

Liners

Glass liners are available for both 1

gallon and 1.5 gallon vessels. These liners

slide into the cylinder. Although they will not

keep corrosive vapors from reaching the

surfaces of the cylinder and head, they

make it much easier to add and remove

liquid reactants, and they give some

protection to the cylinder when working with

corrosive solutions.

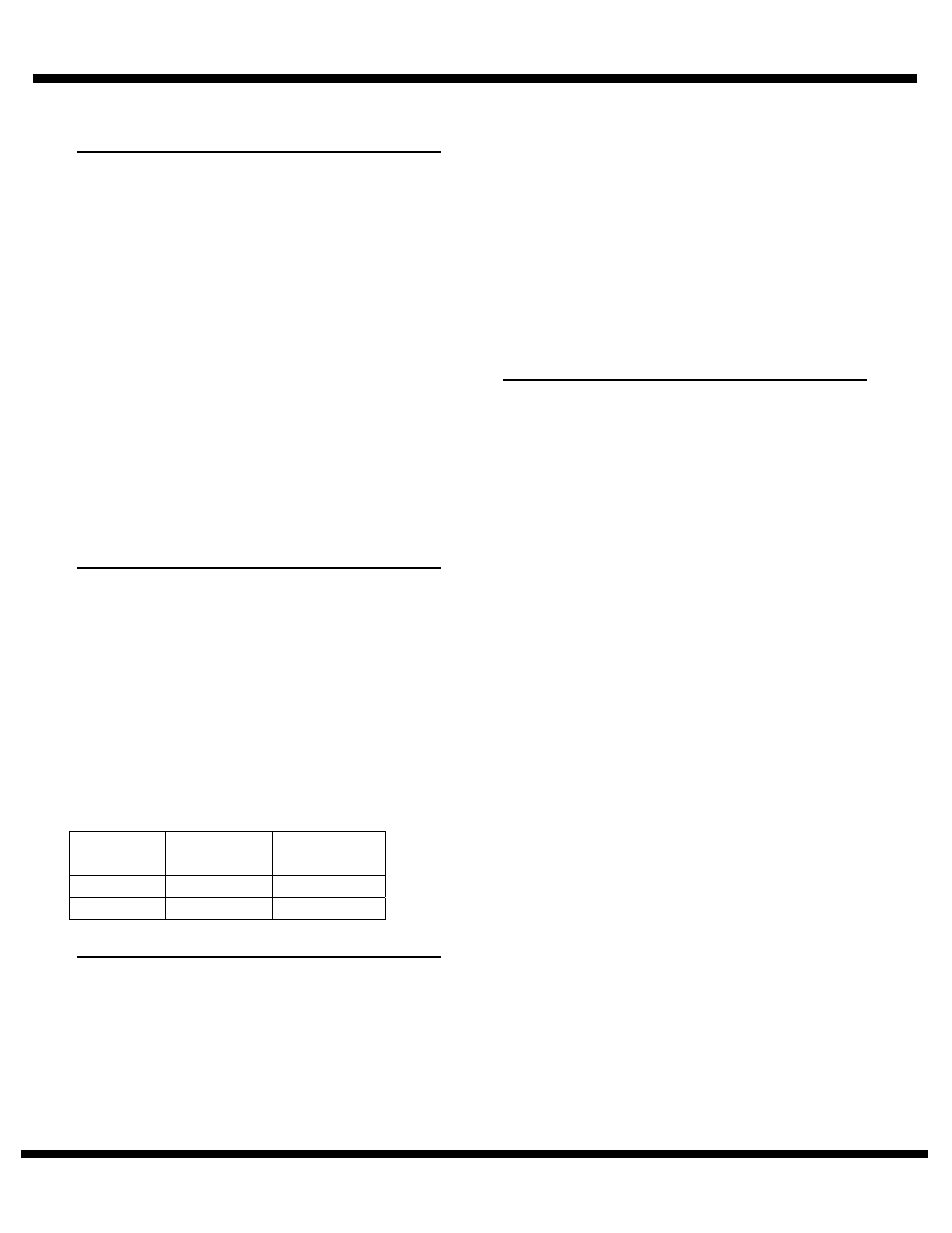

Liner Part Numbers

Fits

ID

Cylinder

Size

Glass

Liner

5.50” 1

Gallon

1996HC

5.50” 1.5

Gallon

1996HC2

Spare Parts Kit

Spare parts kits are available for these

reactors. The kits will provide a reserve

supply of parts and tools sufficient to handle

most normal replacements and emergency

repairs during a year of heavy usage.

The kits contain small perishable items

required for continuous operation including

gaskets, bushings, rupture discs and seals.

They can be ordered from any Parr Dealer

or direct from the Parr Instrument Company.

The order must specify the reactor size and

indicate type of rupture disc, stirrer drive and

type of gasket. It is most advantageous to

provide the complete vessel serial number

from the head or cylinder.

Air Motor

Variable stirring speeds from 100 to 2000

rpm with no electrical spark hazard can be

obtained by replacing the standard motor

with an air motor. This motor operates on

compressed air which must be supplied at

40 psig minimum pressure with at least

10CFM available at that pressure. It is

furnished with a speed control valve and

oiler, all assembled on a mounting bracket.

To operate reactors equipped with an air

motor, mount the drive system firmly on the

support stand and connect the air hose to a

compressed air line. Fill the oiler with SAE

10 oil and adjust the oiler to feed one drop

per minute into the air stream. For long

continuous runs at high speeds, the oiling

rate should be increased to three drops per

minute. If the motor becomes sluggish,

flush it with a non-flammable solvent in a

well ventilated area. Disconnect the air line

and muffler and pour a small amount of

solvent into the inlet port. Rotate the shaft

by hand in both directions for a few minutes;

then connect the air line and run the motor

until there is not further trace of solvent in

the exhaust. If the muffler felts are dirty,

wash them in solvent or replace them.

Relubricate the motor with a squirt of oil into

the chamber and reassemble. If it becomes

necessary to disassemble the motor to

replace the vanes, follow directions given in

the instruction sheet published by the Gast

Manufacturing Corp., Benton Harbor,

Michigan.