Parr Instrument Series 4520 User Manual

Page 17

- 17 -

4520 Bench Top Reactors

Parr Instrument Company

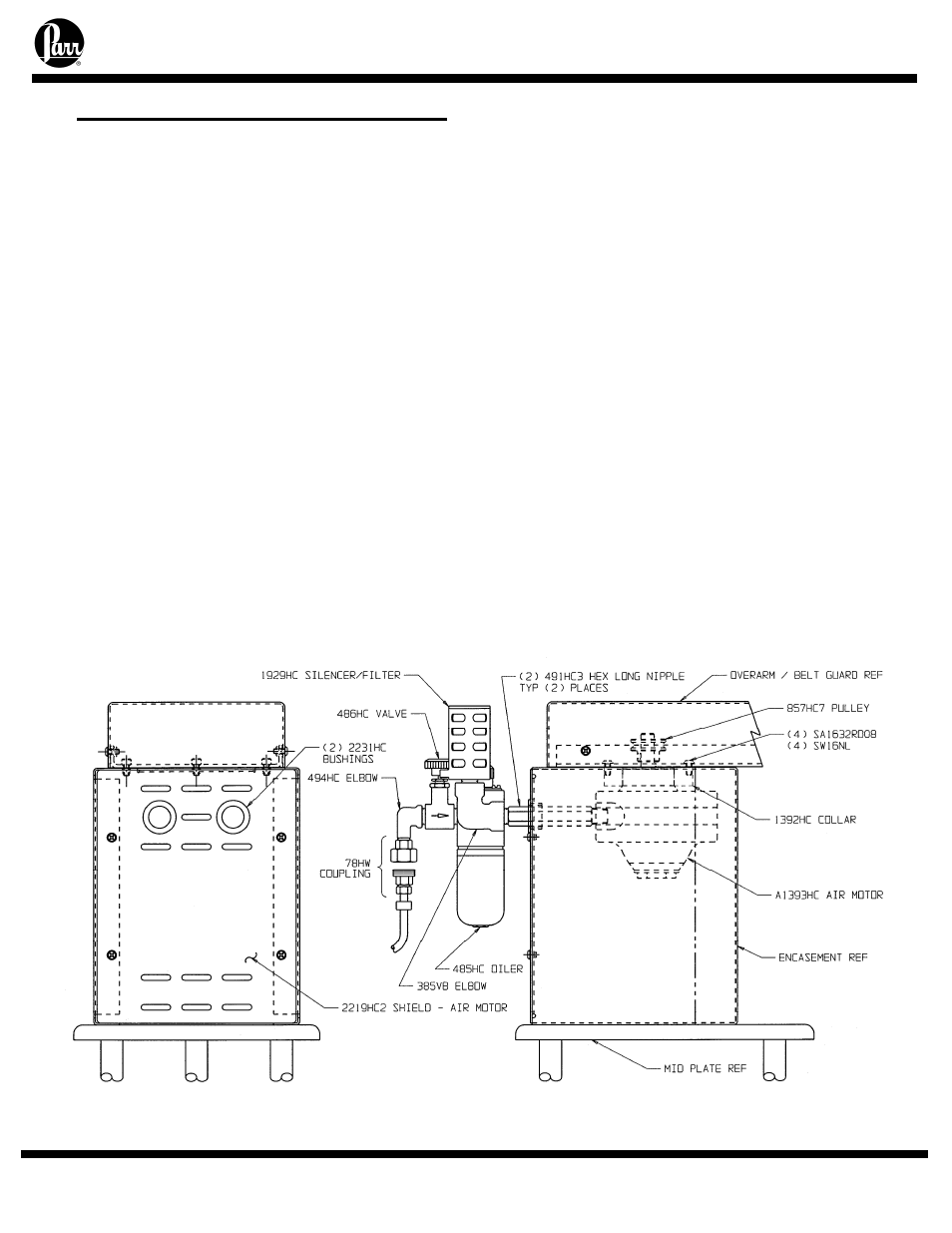

Air Motor

Variable speeds from 100 to 2000 rpm

can be obtained by replacing the standard

motor with an A1393HC air motor assembly.

This motor operates on compressed air

which must be supplied at 40 psig minimum

pressure with at least 10 CFM available at

that pressure. It is furnished with a speed

control valve and oiler, all assembled on a

mounting bracket.

To operate reactors equipped with an air

motor, mount the assembly firmly on the

stand and connect the air hose to a

compressed air line. For best torque and

speed control the piping to the motor should

be at least 1/4" IPS or larger. Fill the oiler

with SAE 10 oil and adjust the oiler to feed

one drop per minute into the air stream. For

long continuous runs at high speeds the

oiling rate should be increased to three

drops per minute.

If the motor becomes sluggish, flush it

with a non-flammable solvent in a well

ventilated area. Disconnect the air line and

muffler and pour a small amount of solvent

into the inlet port. Rotate the shaft by hand

in both directions for a few minutes; then

connect the air line and run the motor until

there is no further trace of solvent in the

exhaust.

If the muffler felts are dirty, wash them in

solvent or replace them.

Re-lubricate the motor with a squirt of oil into

the chamber and reassemble.

If it becomes necessary to disassemble

the motor to replace the vanes, follow the

directions given in the instruction sheet

published by the Gast Manufacturing

Corporation, Benton Harbor, Michigan.

Air Motor Option