Accessories – Parr Instrument Series 4520 User Manual

Page 16

- 16 -

4520 Bench Top Reactors

Parr Instrument Company

ACCESSORIES

Internal Cooling Coils

Cooling coils may be installed in any of

these reactors. The heads of the one and

two liter vessels are drilled with 1/8” NPT

connections on the top and underside of the

head. These openings will have plugs

installed if a cooling coil was not required

when the system was furnished.

The standard cooling coil is a serpentine

configuration. These coils provide an

effective cooling area and may be used with

either a Pyrex or PTFE liner. An optional

spiral coil is available which offers a larger

surface area for cooling but it is more difficult

to clean. The spiral coil can not be used

with an internal liner and it may not

coordinate with other optional internal

fittings.

The A160HW3 solenoid valve package is

recommended for use with the internal

cooling coil. This package includes the

solenoid valve, a metering valve and the

parts required to automate and control the

cooling process. This assembly will connect

to the cold water line, the cooling coil and to

the temperature control. Cooling will then be

admitted to the coil whenever cooling is

called for by the temperature control. This

system is particularly advantageous when

holding fixed temperatures below 150 °C or

to control exothermic reactions.

Alternate plugs are available to close

these ports when the coil is removed.

The replacement of a cooling coil will

require new nuts and ferrules for installation.

Align the replacement coil with the internal

fittings before tightening the nuts. Once the

nuts are tightened it may be necessary to

manually squeeze or slightly adjust the

serpentine loops of the coil to position it

properly for clearance.

If an internal cooling coil is not required

these two ports may be used for alternate

fittings such as an additional valve with a

second dip tube.

Liners

Glass or PTFE liners can be furnished to

fit most Parr reactors. These liners slide into

the cylinder. Although they will not keep

corrosive vapors from reaching the surfaces

of the cylinder and head, they make it much

easier to add and remove liquid reactants,

and they give some protection to the cylinder

when working with corrosive solutions. It

must be noted, however, that adding a liner

will slow the heat transfer rate into the

vessel, and it may be necessary to adjust

the temperature control method to prevent

overheating.

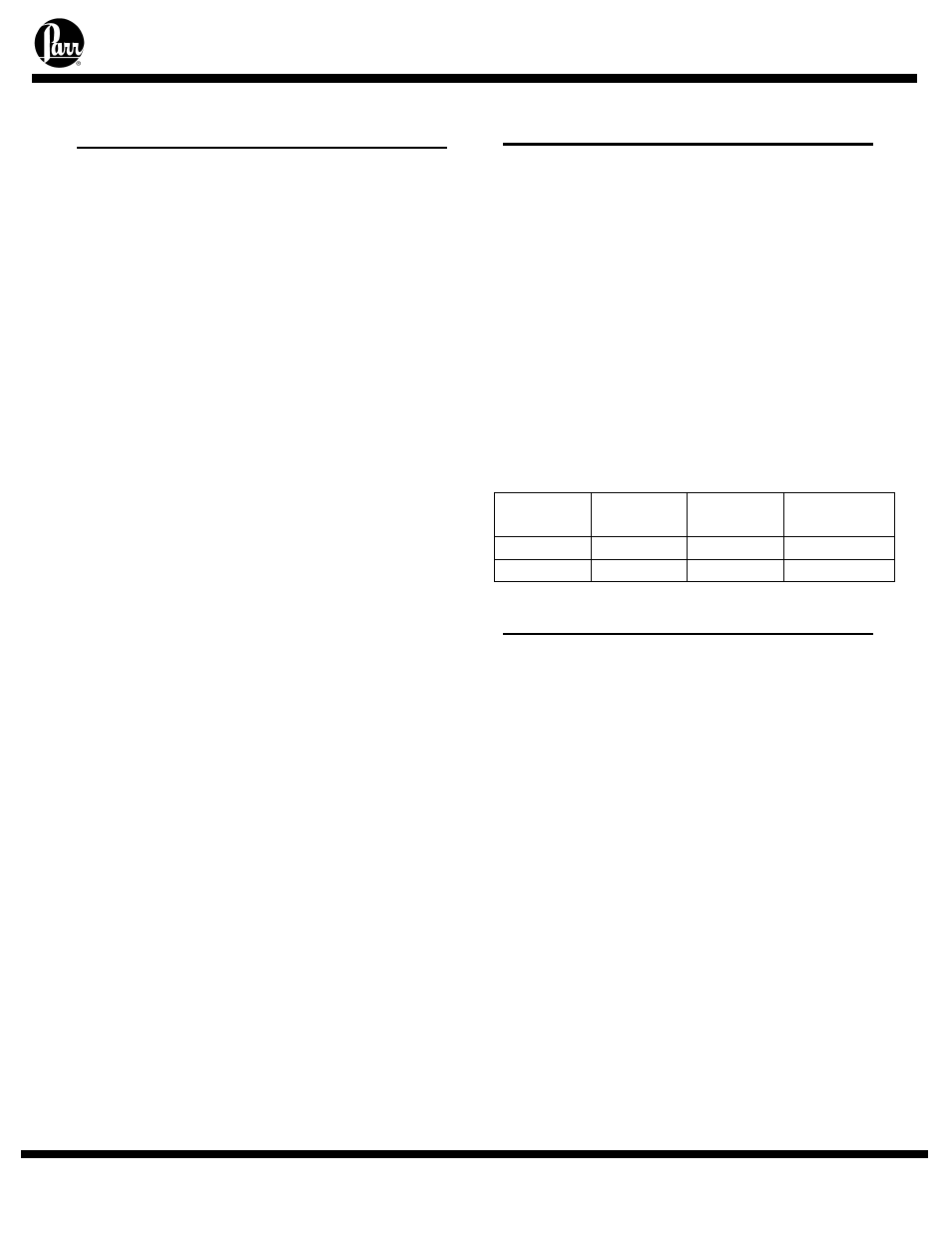

Liner Part Numbers

Fits

ID

Cylinder

Size

Glass

Liner

PTFE

Liner

4” 1000

mL

398HC

398HCHA

4” 2000

mL

399HC

399HCHA

Spare Parts Kit

Parr can furnish spare parts kits for these

reactors which will provide a reserve supply

of parts and tools sufficient to handle most

normal replacements and emergency repairs

during a year of heavy usage.

These kits contain replacement gaskets,

packing, O-rings, shafts, bearings, and

rupture discs. They can be ordered from

any Parr Dealer or direct from the Parr

Instrument Company. The order must

specify the reactor size and indicate type of

rupture disc, stirrer drive and whether it has

a flat-gasket or O-ring closure. Always

provide the reactor serial number (stamped

on head and cylinder) to assure receipt of

proper replacement parts.