Samples and sample holders, Particle size and moisture content, Combustion aids – Parr Instrument 1108P User Manual

Page 8: Sample pellets, Combustion capsules, 1108p oxygen combustion vessels

P a r r I n s t r u m e n t C o m p a n y

8

1108P Oxygen Combustion Vessels

Samples and Sample Holders

Particle Size and Moisture Content

Solid samples burn best in an oxygen bomb when

reduced to 60-mesh, or smaller, and compressed

into a pellet with a Parr Pellet Press. Particle size is

important because it influences the reaction rate.

Large particles may not burn completely and small

particles are easily swept out of the capsule by

turbulent gases during the rapid combustion. Com-

pression into a pellet is recommended since a pellet

burns less vigorously than a loose sample, resulting

in fewer incomplete combustions.

Materials such as coal burn well in the as-received

or air-dry condition, but DO NOT BURN BONE-DRY

SAMPLES. A certain amount of moisture is desir-

able in order to control the burning rate. Very dry

samples may burn so rapidly that a flame might

reach the seals or the soft valve seat in the bomb

head, igniting these parts and possibly causing a

serious burn-out through the head. Moisture con-

tents up to 20% can be tolerated in many cases, but

the optimum moisture is best determined by trial

combustions. If moisture is to be added, drop water

directly into a loose sample or onto a pellet after the

sample has been weighed; then let the sample stand

for awhile to obtain uniform distribution.

Combustion Aids

Some samples may be difficult to ignite, or they

may burn so slowly that the particles become chilled

below the ignition point before complete combus-

tion is obtained. In such cases benzoic acid, white oil

or any other combustible material of known purity

can be mixed with the sample. Ethylene glycol,

butyl alcohol or decalin may also be used for this

purpose. It must be remembered, however, that a

combustion aid adds to the total energy released in

the bomb and the amount of sample may have to be

reduced to compensate for the added charge. If ben-

zoic acid is added as a combustion aid, it must be

added in a pellet form, .2 gm pellets. Never combust

benzoic acid in powder form.

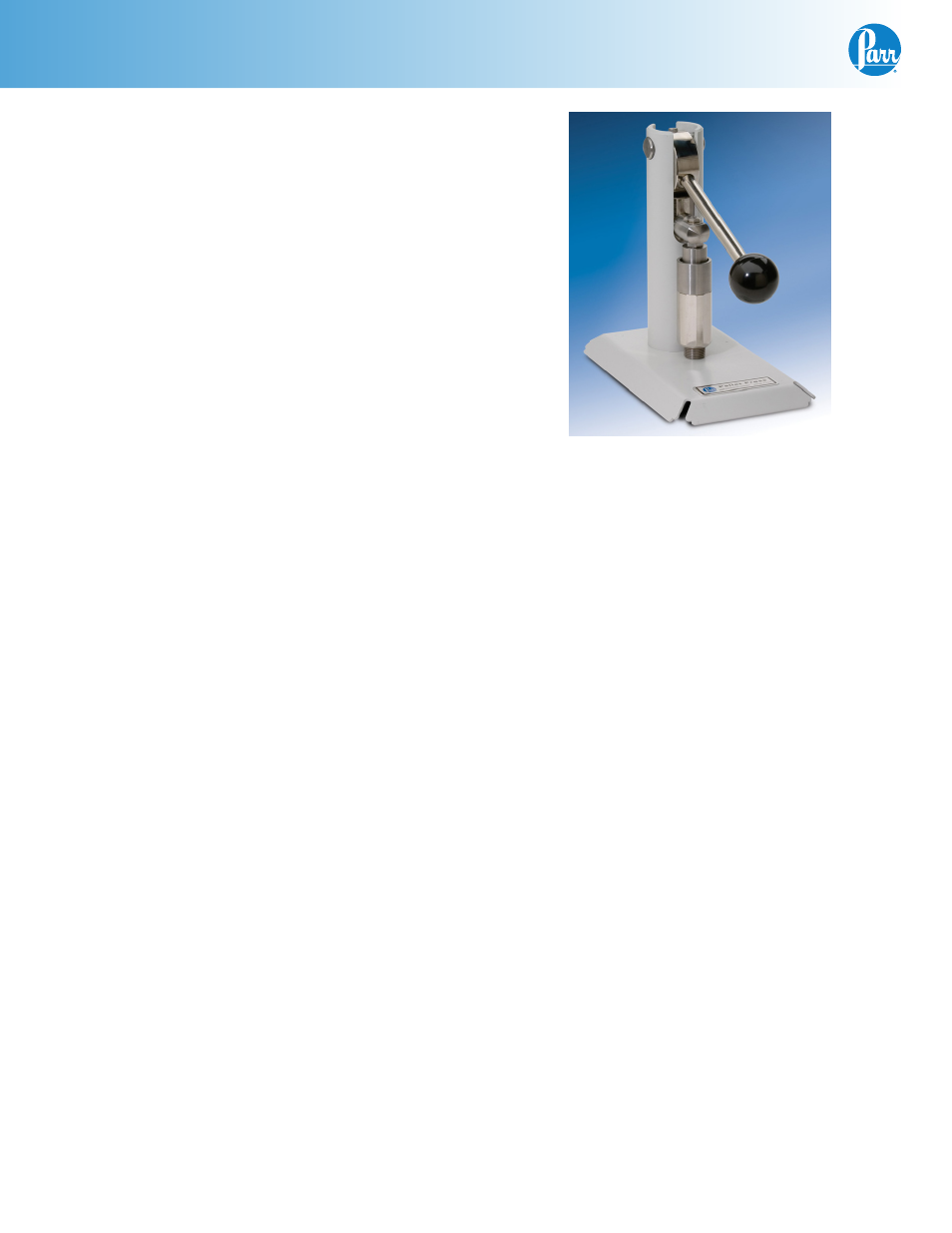

Sample Pellets

One of the most useful techniques for handling

powdered samples is to compress the material into

a tablet or pellet before it is weighed. Pellets are

easier to handle than loose samples and they burn

slower in the bomb, thereby reducing the chances

for incomplete combustion. The Parr pellet press

offers a convenient means for preparing samples

in this manner. Pellets produced in this press are

ejected into a stainless steel receiver from which

they can be lifted and handled easily with a pair of

forceps. Most pellets for use in the 1108P Oxygen

Combustion Vessel are made in a one-half inch di-

ameter size, but smaller diameters can be produced

in the same press using interchangeable punch and

die sets. Complete pellet making instructions are

furnished with each press.

Combustion Capsules

Non-volatile samples to be tested in Parr oxygen

vessels are weighed and burned in shallow capsules

measuring approximately 1” diameter and 7/16”

deep. These are available in stainless steel, fused

silica and platinum alloyed with a 3-1/2% rhodium.

Stainless steel capsules are suitable for all tests

except those in which a non-metallic (fused silica)

holder is desired or where the superior corrosion

resistance of a Pt-Rh cup is required. Fused silica

capsules should be used for samples containing

dissolved metals which can ignite a stainless steel

capsule and cause serious bomb damage.

Stainless steel capsules will soon acquire a dull grey

finish after repeated use in an oxygen bomb due to

the formation of a hard, protective oxide film. This

dull finish not only protects the capsule but it also

promotes combustion and makes it easier to burn

the last traces of the sample. It is recommended,

therefore, that capsules be heated in a muffle fur-

nace at 500°C for 24 hours to develop this protective

coating uniformly on all surfaces. This treatment

should be performed after a capsule has been pol-

2811 Pellet Press