Step 5, Step 6 step 7 – ParkZone PKZ4675 User Manual

Page 4

7

8

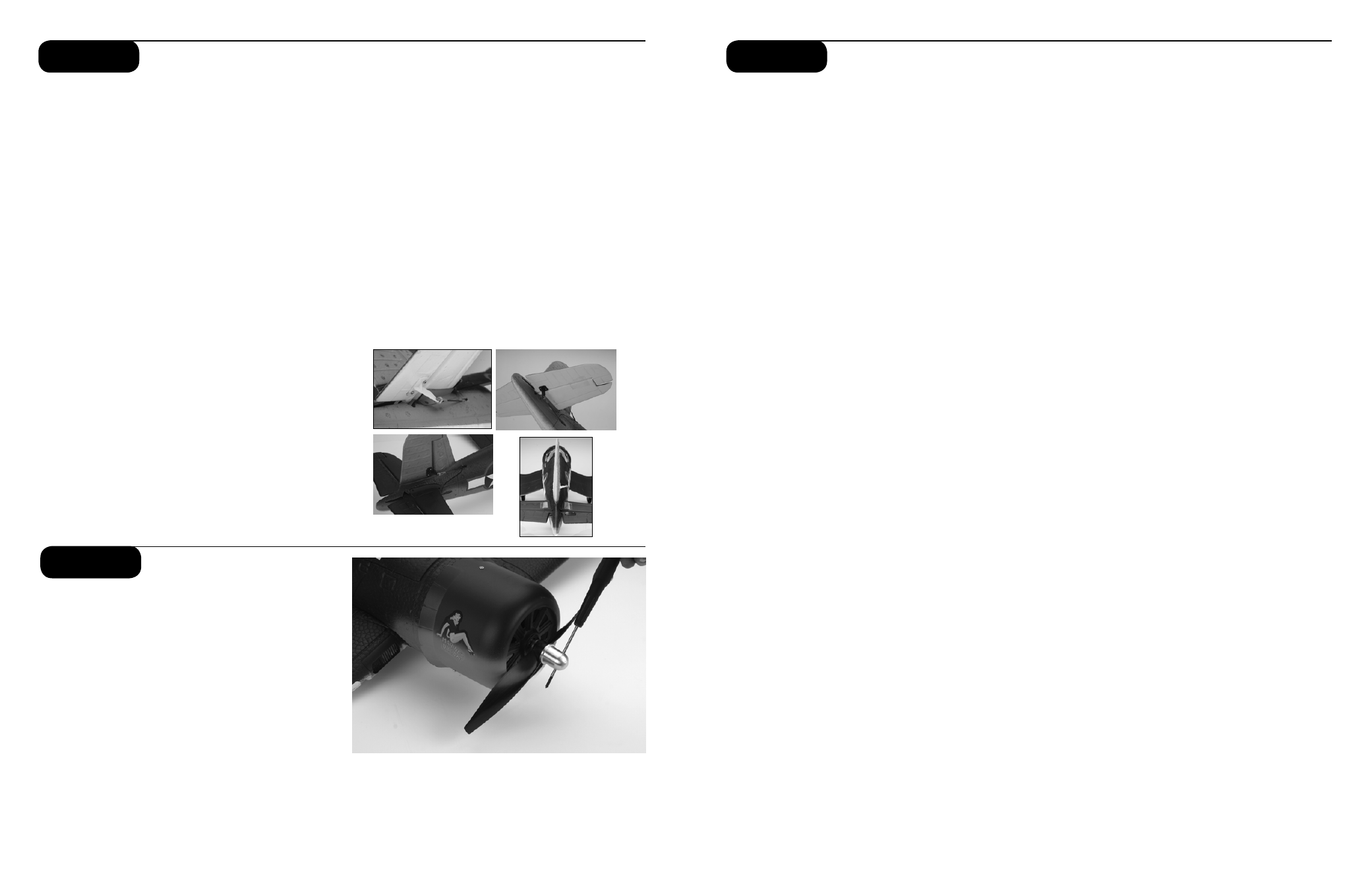

Attaching the Horizontal Stabilizer

1. Locate the horizontal stabilizer of the tail.

2. Slide the horizontal stabilizer in the allotted space

of the fuselage, making sure the control horn

installed in the elevator will properly align with the

pushrod and clevis exiting the back of the fuselage.

3. When you are certain the horizontal stabilizer is

centered correctly and in the right place, use the

tape provided to properly secure the stabilizer to

the fuselage. Use the tape on the top and bottom

of each side of the horizontal stabilizer (total of 4

applications).

4. Make sure the throttle stick is in the full down (idle)

position. Turn on the transmitter and plug in the

flight battery.

5. Locate the lower clevis and pushrod exiting the

right side of the fuselage, and attach the clevis to

the outermost hole on the elevator control horn.

Slide the included retainer over the clevis to ensure

the clevis will not open.

6. Make any trim adjustments as necessary prior to

flight (see step 7).

Note: To make trim adjustments to the horizontal

stabilizer:

a. Confirm the throttle stick is in the full down (idle)

position and turn on the DX5e transmitter.

b. Connect the blue EC3 battery connector into the

EC3 device connector on the speed control.

c. Use the elevator trim of the radio by moving up or

down to achieve neutral position when the gimbal is

also at neutral. If these changes are not sufficient,

center the transmitter elevator trim (distinguished by

a long tone), then remove the clevis from the elevator

control horn and turn clevis in or out as needed to

move the elevator alignment back to neutral.

Warning: Always keep hands and all objects away

from the propeller in case the motor is engaged.

A moving propeller can cause severe injury and

damage.

Step 5

Installing or Replacing the Propeller and

Spinner

Your F4U Corsair has come with 2 different propellers.

• The 2-blade (installed) propeller is slightly more

efficient and offers a little more thrust.

• The 3-blade propeller allows for more scale-type

flights, yet performs very well.

1. Remove the prop hub by inserting a hex driver

through the holes drilled in the hub. Carefully

grasp the propeller and turn the prop hub counter-

clockwise to loosen the hub.

2. Slide propeller on. Make sure pitch numbers on

prop are visible from the front of the airplane.

3. Re-install the prop hub by turning it clockwise. The

hex driver should be used as in Step 1 to ensure

the hub is tight.

NOTE: Always confirm the flight battery is unplugged

from the speed control prior to working around the

propeller and cowl.

Step 6

Step 7

30A ESC instructions

The E-flite 30A Pro Brushless ESC is a lightweight, high-

quality, efficient sensorless brushless electronic speed

control with an integrated switch-mode BEC. It can oper-

ate without the need for a separate receiver battery to

power your servos and receivers, saving you weight and

complication. It is capable of up to 30 amps continuous

current when using 3- to 4-series LiPo battery packs.

You can drive up to 5 analog or 4 digital sub-micro-sized

servos with the BEC on any recommended input voltage.

This ESC also features safe power arming along with

advanced programmable features such as low voltage

cutoff, braking, timing, throttle input range, and more,

making this truly a ‘pro series’ speed control. The ESC

installed in the F4U Corsair has been pre-programmed

for 3S low voltage cut-off.

Note: ALWAYS assume the motor and the propeller

are live. ALWAYS keep clear of the propeller at all

times. The high rpm of the brushless motor can

cause severe injury.

E-flite 30-Amp ESC Features:

• Up to 30 amps continuous current with proper air

flow and 35 amps burst current (15 seconds)

• 5V switch-mode BEC capable of 700mAh

continuous current on any recommended

input voltage

• Drive up to 5 analog or 4 digital sub-micro-sized

servos with the BEC on any recommended

input voltage

• 3- to 4-cell LiPo, 9- to 12-cell NiMH/NiCd

input voltage

• Programmable motor braking

• Safe power-arm mode prevents accidental starts

• Programmable low voltage cutoff with settings

for 3-cell LiPo (9.2V), 4-cell LiPo (12V), or 74% of

battery starting voltage

• Programmable throttle input range (1.1ms–1.9ms

or 1.2ms–-1.8ms)

• Programmable soft start for helis and airplanes

• Auto motor shut down if signal is lost or there is

interference

• Programmable timing—5 user-selectable ranges–

use with a large variety of brushless motors

• Optional RS232 Serial Link and software available

for PC programming (EFLARS232)

• Pre-wired connectors—E-flite EC3 on battery input

and 3.5mm female gold bullets on motor

output leads

Specifications

Continuous Current: 30A*

Max Burst Current:

35A (15 sec)*

Length:

51mm (2 in)

Width:

28mm (1.1 in)

Height:

8.7mm (.35 in)

Weight:

31 g (1.1 oz)

Cells:

3-4S LiPo or 9-12 NiMH/NiCd

Battery Input Leads: 16 AWG with E-flite

EC3 Connector

Motor Output Leads: 16 AWG with 3.5mm Female

Gold Bullet Connectors

* Proper cooling required

Optional RS232 Serial Link & Programming Software

Programming your ESC will be much faster and easier

when you purchase the optional RS232 Serial Link and

programming software. This will allow you to update

your ESC using a laptop or PC. You must have a Serial

Port on your computer or you can purchase a separate

USB to DB9 adapter (available at computer retailers).

EFLARS232—RS232 Serial Link/Programming Software

Servo Ratings with BEC Enabled:

Drives up to 5 analog or 4 digital sub-micro-sized servos

with the BEC on any recommended input voltage.

Some servo combinations we have tested in various

models include:

• 1 analog standard servo, 1 digital sub-micro servo,

2 analog sub-micro servos—E-flite Apprentice

15e RTF

• 2 ParkZone (PKZ1081) analog sub-micro servos

and 2 ParkZone (PKZ1090) digital metal gear

sub-micro servos—ParkZone T-28 Trojan RTF &

F4U Corsair RTF

Some other brands and models of servos may have

significantly higher current draw. Digital servos and

binding servos of any kind typically have higher current

draw. As a general rule, micro and sub-micro servos

draw less current which may affect your servo usage

as shown in the examples above. We recommend the

use of a Hangar 9 Servo and Receiver Current Meter

(HAN172), installed between the throttle lead of the

ESC and receiver, to confirm current draw of the actual

servos used. Also, always be sure to position the ESC

for maximum airflow since cooling can significantly aid

in the performance of the BEC.