Isolation valves, Bakeable all metal valves, Replacement seals – Nor-Cal Metal Valve User Manual

Page 3: Torque specifications

3

Isolation Valves

Ultra-High Vacuum Components Since 1962

•

www.n-c.com

3

SECTION 3.11

C

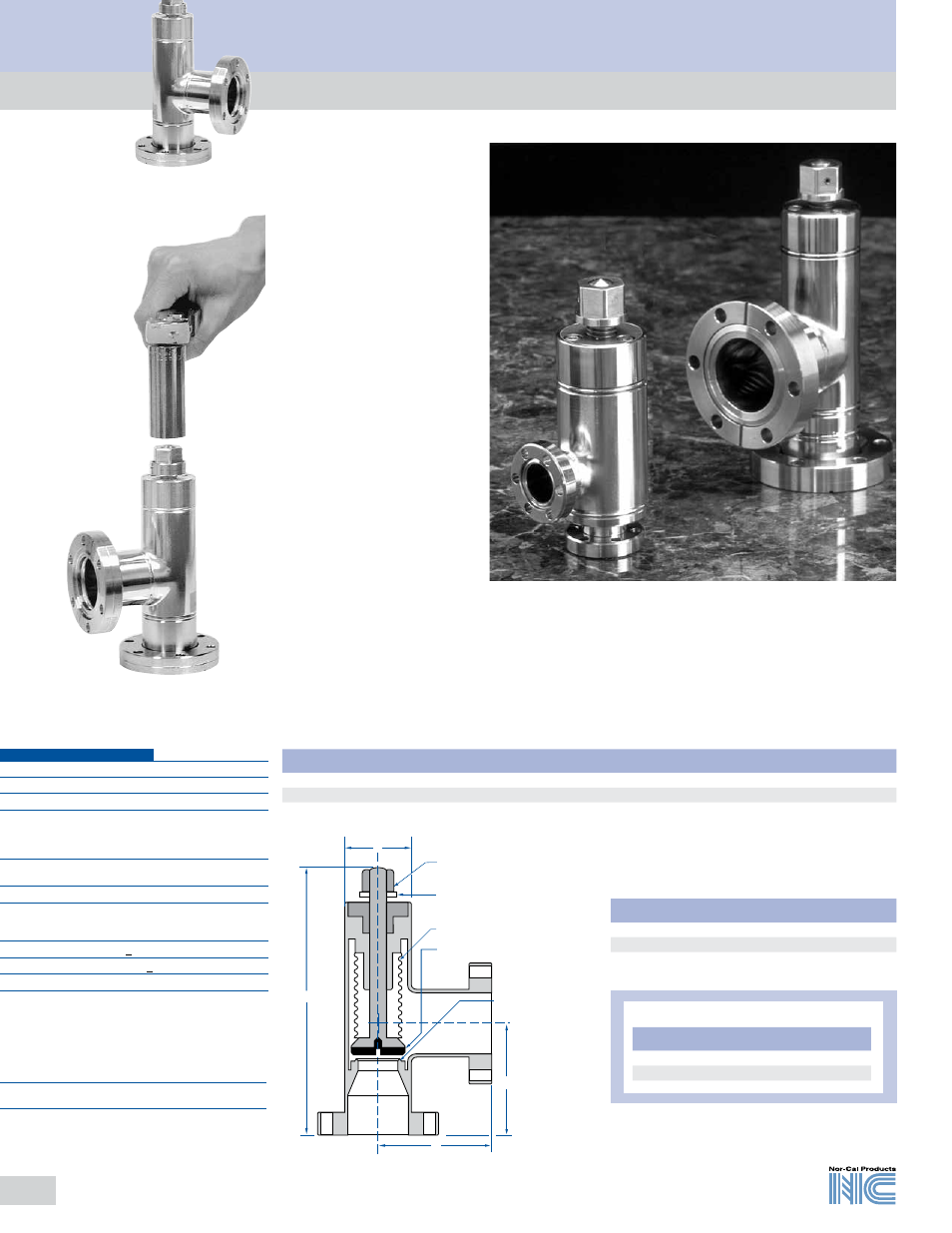

Indicator collar

with set screw

Closure nut

321 stainless steel bellows

Copper poppet seal

B

A

A

S.S. knife

edge seal

Bakeable All Metal Valves

MODEL

NUMBER

NOMINAL

PORT OD

FLANGE

TYPE

CONDUCTANCE (L/sec )

MOLECULAR VISCOUS

A

(OPEN)

B

C

AMV-0752-CF

3

/

4

(19)

Rotatable 1.33 CF

3

56

1.50 (38)

5.40 (137)

1.50 (38)

AMV-1502-CF

1

1

/

2

(38)

Rotatable 2.75 CF

10

356

2.45 (62)

6.87 (175)

1.50 (38)

NOTE:

Port lengths that match other manufacturers’ products are available upon request.

Replacement Seals

MODEL

NUMBER

NOMINAL

PORT OD

AMV-075-95

0.75 (19)

AMV-150-95

1.50 (38)

Nor-Cal’s metal seal angle valves are

intended for use in UHV or cryogenic

applications where temperature extremes

preclude the use of our elastomer seal

valves. Approved for use in beamline

facilities, these valves have a temperature

operating range from -250°C to 400°C.

Heater jackets and controllers are

available on request.

The pulled-port method is used for

the fabrication of the stainless steel

bodies resulting in higher conductance

and better cleanliness. Heater jackets

and controllers are available on request.

The life of the copper poppet seal is

dependent upon the temperature at

which the valve is used. Maximum

temperature bakeouts may require copper

poppet seal replacement after 50 cycles,

while hundreds of cycles are possible

with moderate bakeouts. As many as

10,000 cycles have been obtained

from the same seal during testing.

A dial indicator at the top of the valve

indicates the proper torque for closure

and also when the seal should be replaced.

The copper poppet seal is easily replaced

by opening the valve with a slotted screw

driver. The seal is removed through the

side port and a new one replaced in a

like manner. After seal replacement the

valve must be torqued to a higher value

than during normal operation to make it

seat. Do not exceed the maximum torque

Torque Specifications

MODEL

NUMBER

SEATING

Nm

NORMAL

Nm

MAXIMUM

Nm

AMV-075-CF

6.8

5.6

13.6

AMV-150-CF

13.6

11.3

22.6

specifications. (See torque specifica-

tions table.) After closing the valve to its

normal torque value loosen the set screw

below the closure nut, rotate the indica-

tor to the furthest counter-clockwise line

on top of the valve and retighten the set

screw. The valve may be closed to this

mark indefinitely. Periodic checks with a

torque wrench will indicate seat wear

and the proper mark to use for alignment.

When the indicator has reached the last

mark we recommend seal replacement.

SPECIFICATIONS

Port ODs:

3

/

4

and 1

1

/

2

inch (19 to 38mm)

Finish: Electropolished

Assembly: Clean room

Materials

Pulled port body: 304 stainless steel

Bellows: Formed 321 stainless steel

Poppet seal: OFHC Copper

Actuation: Manual using self-lubricating

bronze nuts with ACME threads

Operating temperature: -250ºC to 400ºC

Maximum bakeout temperature

Open:

400°C

Closed: 300°C

Vacuum rated: >1x 10

-10

mbar - UHV

Helium leak rate: <10

-10

mbar l/sec.

Options: Heater jackets and controllers

All dimensions are in inches (mm) & weights

are in pounds (kg), unless otherwise noted.