Maintenance & service, Periodic maintenance checking the control system, Checking the connections – Dometic RM2551 User Manual

Page 14: Checking the lp gas pressure, Cleaning the flue baffle and burner, Warning

- 14 -

perioDic maintenance

checking the control system

Check the control system by connecting/disconnecting the

120V aC power, starting/stopping the engine, etc.

checking the connections

Check all connections in the lP gas system (at the

back of the refrigerator) for gas leaks. The lP gas

supply must be turned on.

apply a non-corrosive bubble solution to all lP gas

connections. The appearance of bubbles indicates a

leak and should be repaired immediately!

checking the lp gas pressure

The lP gas pressure should be checked and the main regulator

readjusted if pressure is incorrect. The correct operating pres-

sure is 11 inches of water column. Measure the lP gas pressure

at the test port, just ahead of the burner jet.

Cleaning the flue baffle and burner

Inspect the flue baffle. It should be reasonably clean and free

of soot. Heavy soot formation indicates improper functioning

of the burner.

To clean the flue and burner, follow these steps:

Turn off the refrigerator.

unplug the power cord from the 120V aC outlet.

Disconnect the wires or shut off the 12V DC power

supply to the refrigerator.

Turn off the manual shut off valve.

Remove cover from burner housing. Remove the

burner mounting screws and then, the burner as-

sembly.

1.

2.

1.

2.

.

4.

Remove the wire and flue baffle from the top of the

flue tube.

using a flue brush, clean the flue from the top. Blow-

ing compressed air into the flue will not properly

clean soot and scale out of the flue tube.

Put back the flue baffle.

Clean the burner tube with a brush. Blow out the

burner with compressed air.

Remove burner jet, but first, clean burner area of

soot and scale that fell out of flue tube.

Remove the burner jet.

soak the jet in wood alcohol and blow it out with

compressed air.

Reinstall and tighten the burner jet.

Reinstall the burner. Ensure the end of the burner fits

into the slot on the burner bracket. Verify that the

slots are centered under the flue tube and the thermo-

couple is positioned properly (tip of thermocouple

extends over two slots of burner).

Check the electrode for proper location and gap.

Turn on the manual gas shut off valve.

Examine all fittings for leaks. (use a commercial

non-corrosive bubble solution.)

Connect the 120V power cord. Reconnect/turn on

the 12V DC power.

Check the lP gas safety shut off.

5.

6.

.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

maintenance & service

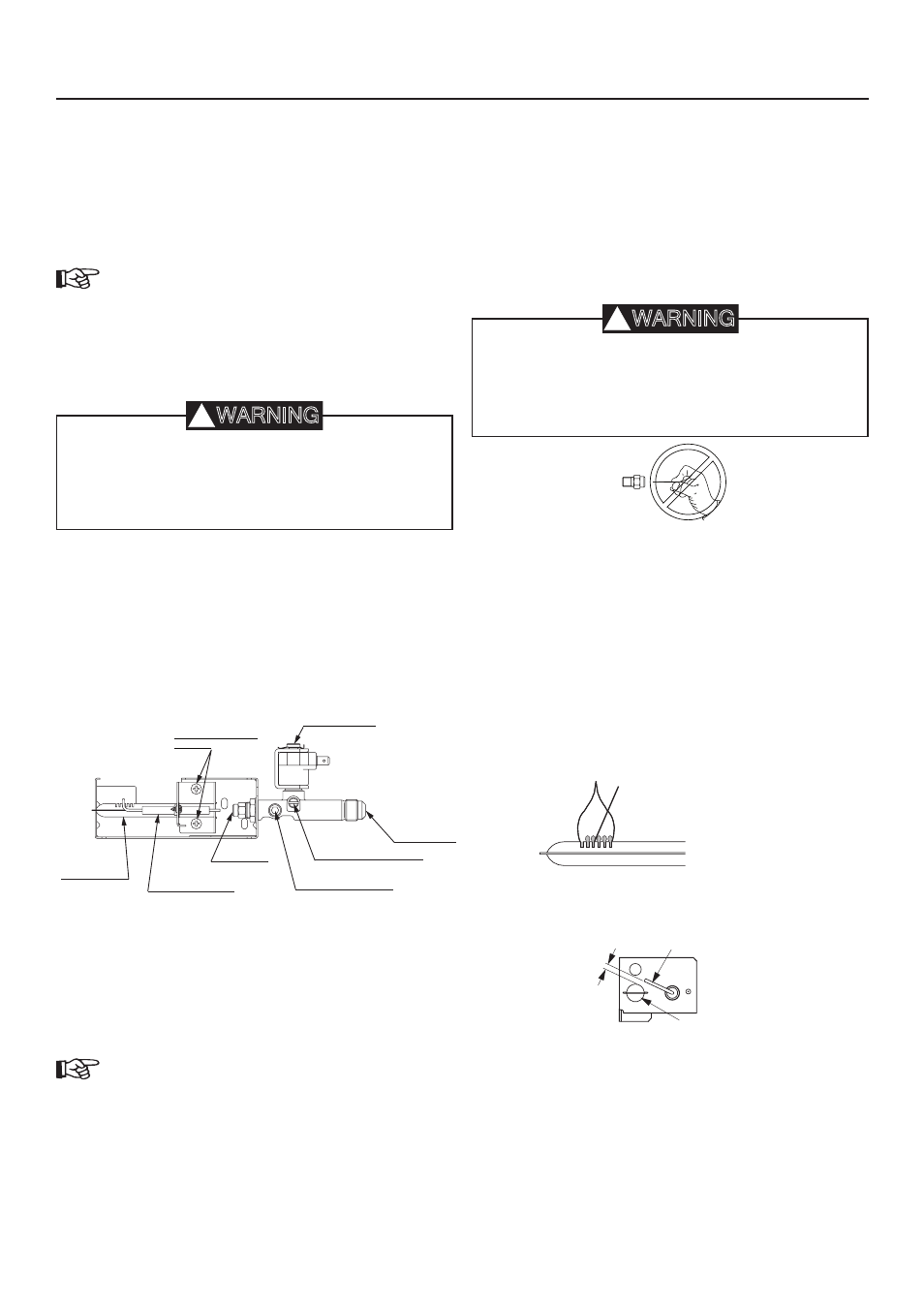

BURNER TUBE .

SPARK ELECTRODE

BURNER JET

BURNER MOUNTING

SCREWS

PRESSURE TEST PORT

MANUAL SHUT OFF VALVE

(Shown in open position)

INLET FITTING

SOLENOID VALVE

gas equipment assembly

Electrode

Burner tube

1/8” to 3/16”

(3-5 mm)

4HE

FIRE HAZARD. Do not use a wire or pin when

cleaning the burner jet as damage can occur to

the precision opening. Failure to heed this warn-

ing could cause fire resulting in personal injury.

WARNING

!

EXPLOSION HAZARD. Never use an open

flame to check for gas leaks. Failure to heed this

warning could cause an explosion resulting in

death or severe personal injury.

WARNING

!