Hope Tech V-Twin Brake User Manual

Page 2

INSTALLATION STEPS

PERSONAL SETTINGS

BREAK IN PERIOD AND MAINTENANCE

2. ATTACHING THE DISC TO THE HUB

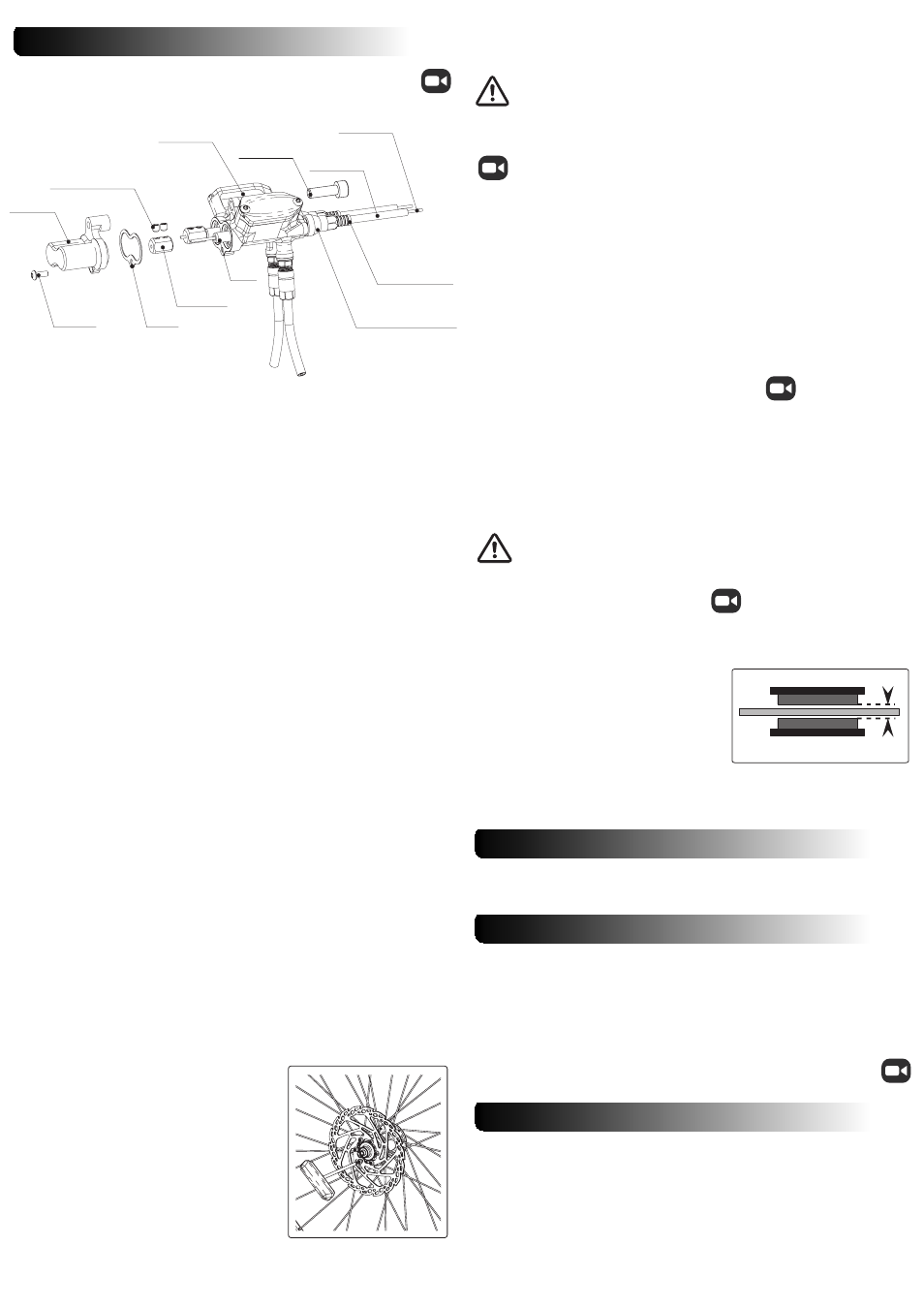

1. INSTALLING AND CONNECTING THE V-TWIN MASTER CYLINDER UNIT

3. ATTACHING THE CALIPER TO THE FORK OR FRAME

4. CENTRALISE THE PADS OVER THE DISC

V-Twin X2/10.11/ISS1

3.2 MOUNTING THE CALIPER ON IS TYPE MOUNTS

=

=

pad

pad

rotor

WARRANTY

All Hope Technology disc brake systems are covered for one year from original

date of purchase against manufacturer defects in material and workmanship. Proof

of purchase is required. Products must be returned to the original place of purchase or

to Hope Technology to process any warranty claim.

This warranty does not cover any damage caused through mis-use or failing to

comply by the recommendations given in this manual.

This warranty does not affect your statutory rights.

3.1 MOUNTING THE CALIPER ON POSTMOUNT TYPE MOUNTS

a) Before attaching the caliper ensure that the brake pads are fully retracted in the

caliper. If not, gently push the piston back using a plastic tyre lever or

something similar. Beware not to damage the pads. Take them off if

necessary. Push on the left hand side pad backplate to push the right hand side

piston and vice versa.

b) Mount the wheel fitted with the rotor,

ensuring

correct

fitment

in

dropouts.

c) Position the caliper on the mount and slightly tighten the two M6 bolts.

d) At both front and rear of the caliper, adjust its position so it is central over

the rotor then tighten the two M6 bolts using a 5mm Allen key. Recommended

tightening torque 8-9 N.m.

Be careful not to get your fingers caught in the disc when following

these steps.

We do not recommend pumping the lever to push pads out to align

caliper at this point. See section 4 regarding the alignment of pistons.

a) Attach the disc rotor to the hub using the

bolts provided with your disc type (6, 4 or 3

bolts).

b) Make sure that the laser marked arrow on

the disc is pointing in the same direction as the

forward wheel rotation.

c) Depending on the bolt type, using a Torx 25

driver or 5mm Allen key, tighten the disc bolts in a

cross pattern. Recommended tightening torque :

5-6 N.m for M5 bolts, 11-12 N.m for M8 bolts.

Note : A mild engineering adhesive could be

used on disc bolts to prevent them unscrewing.

Do not use permanent adhesive.

1. Remove the existing brakes if present leaving handlebar levers and cables in place.

2. Cut a clean edge on both inner cables before removing it from existing outer cable

to make it easier for re-fitting.

3. Apply the brake lever to gain access to remove both inner cables from the lever

assembly.

4. Install the support plate on steerer tube making sure the master cylinder doesn’t

touch the stem when mounted. The plate mounts between the top headset cover

and the stem. You may need to use some provided headset spacers to achieve the

most suitable position for the master cylinder.

5. Remove the rear end cover and its gasket.

6. Install the V Twin master cylinder assembly under stem and fasten it to the support

plate using the M5 bolt and provided nut whilst the rear end cover is removed.

7. Nicely route the brake cable outer into the V-Twin master cylinder assembly and

cut it so the cable outer sits in the screw on cable tension adjusters. At this point pay

attention to which side of the V Twin master cylinder assembly the front and rear

calipers are attached. Depending if you want the front brake to be operated by the

RH or LH lever route the cable outer to the correct side of the master cylinder.

8. Now re-feed the brake cable inner through the cable outer and throughout the

piston.

9. When the brake cable is coming out of the rear of the V Twin master cylinder

assembly, slide the brass brake cable lock onto the inner brake cable.

10. Whilst pulling the inner brake cable out of the rear of the master cylinder push

the brake cable lock against the piston shoulder taking care NOT to push the piston

itself.

11. When the brass brake cable lock is sitting flush against the piston face gently

tighten the cable with the 2x M4 grub screws.

12. Make sure the brass brake cable lock is sitting against the piston face or very close

to it (1mm clearance maximum)

13. If you have achieved step 12 then proceed to tighten more firmly the brass cable

lock’s 2x M4 grub screw. If not go back to step 10.

14. The screw on cable tension adjuster would allow to take out any play if there is a

gap between the piston face and the brass brake cable lock. If you wish you can leave

the gap and this would result in more free brake lever stroke. But you must always

have a small amount of play or the pads may not self adjust and also pump up when

warm resulting in the brake locking on.

15. Repeat the operations 8 to 14 for the second brake cable.

16. When both brake cables are in place and firmly tightened cut the excess brake

cable. Leave a maximum of 2mm sticking out of the brake cable lock or it may

prevent the rear end cover sitting in place correctly.

17. Re install the rear end cover and its gasket and screw on the M3 torx screw.

18. Then finally bolt the V-Twin master cylinder assembly fitted with its end cover to

the support plate.

On IS mount you will have to use an adaptor bracket to be able to fit the brake

caliper.

a) According to the rotor size and type of mounts, attach the suitable adaptor

bracket onto the brake tabs and tighten the two M6 bolts using a 5mm Allen key.

Recommended tightening torque 8-9 N.m.

b) Follow the same instructions as fitting the brake onto a postmount (see

previous section).

This step is very important and mustn’t be

ignored.

Gently pump the lever in order to bring the

pads closer to the disc. One pad might enter in

contact with the disc before the other. If this

happens, hold the disc against the pad that is

already in contact with the disc to allow the

other one to move.

For an optimised lever feel, both pads must

enter in contact with the disc at the same time

and allow the same clearance (see arrows)

when retracted. The disc should not be flexing

at any time.

Only the brake cable tension is adjustable. The rear end cover must be removed to

proceed. See then step 14 of the master cylinder installation paragraph.

Please refer to the website videos and technical documents if you

require more information about setting up this brake system, servicing

and maintenance. www.hopetech.com / Tech support section

Before riding and before every ride, check the correct action of the brake and that

braking effort is applied as the lever is pulled.

To achieve the maximum braking performance, the new pads will need bedding in.

Please note that sintered pads take longer to bed in than organic pads.

To bed in the pads, ride a short distance whilst alternatively gently applying the

brake on and off without attempting to stop. This procedure will achieve good

braking performance but will reach its full potential after a few rides.

About maintenance tips refers to our “how to” videos on the website.

For brake bleeds use only dot 5.1 or dot 4 brake fluid from a clean container.

Avoid situations that could damage the brake hose and/or your bike frame

and components

Note: In the first instance it is recommended that you install your brake as supplied

without disconnecting and routing the hose through frame guide (if present) or

attempting to shorten the hose.

At a later date you can shorten the brake hose if required. For this operation,

follow the intructions in the how to videos of our website.

Route the hose and caliper down to the fork brake mount or along the frame to the

rear brake mount.

M3 screw

M3 screw

Gasket

Gasket

Brass brake

Brass brake

cable lock

cable lock

M4 grub screw (x2)

M4 grub screw (x2)

V-Twin MCyl

V-Twin MCyl

Assembly

Assembly

Rear

Rear

end cover

end cover

Piston

Piston

Brake cable

Brake cable

inner

inner

Brake cable

Brake cable

outer

outer

Cable outer stop

Cable outer stop

Screw on

Screw on

Cable tension adjuster

Cable tension adjuster

M5 x 16

M5 x 16

cap screw

cap screw