Install drive side outer seal ring – Hope Tech Press-Fit PF46 Bottom Bracket User Manual

Page 2

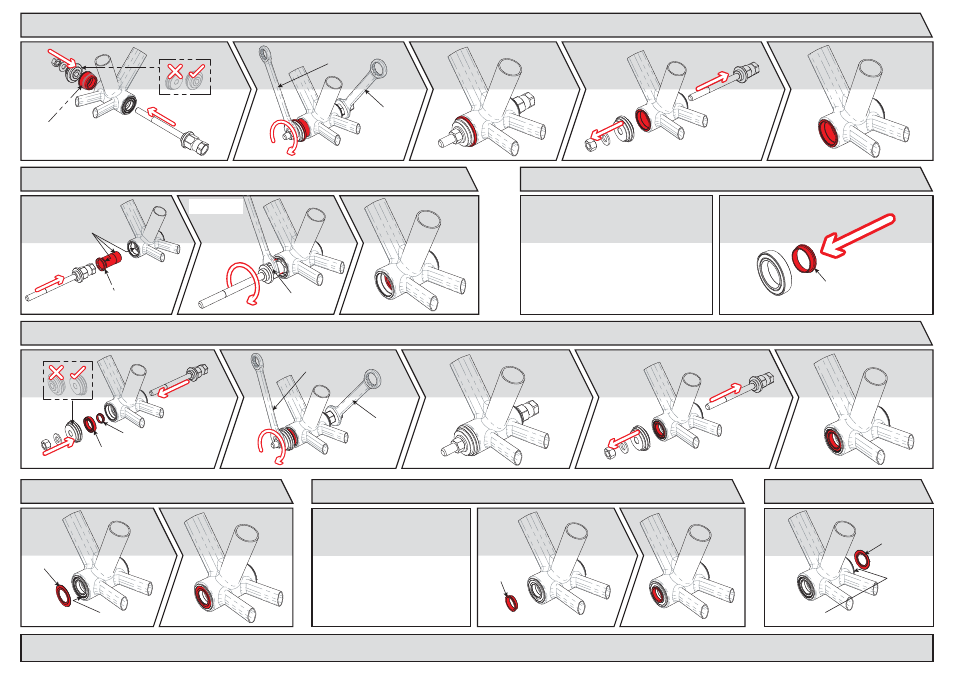

2. Install the non-drive side cup (without bearing fitted).

5. Install the non-drive side bearing.

3. Install the centre tube.

4. GXP conversion only.

If using a GXP style crank set, press one half of

the GXP conversion (BBSP109 - available

separately) into the INNER face of the non-drive

side bearing (alternatively, gently tap into place

with a rubber mallet). Do not install the other

half of the GXP conversion at this stage.

*Only install BBSP109 if using a GXP crank set

Hold this end stationary

using a 27mm spanner

Tighten the nut using a 19mm spanner

until the non-drive side cup is pulled fully

flush with the bottom bracket shell

Tighten the centre tube

using a 27mm spanner.

Tightening torque 27-34 Nm

Bolt-in Centre Tube

BBSP111

GXP Conversion

BBSP109*

GXP Conversion

BBSP109*

Non-drive side cup

(Item No. 4)

Bottom Bracket Bearing

BBSP108

Apply grease to the threads of

the centre tube and the mating

faces of the centre tube and cup

Apply grease to the internal

surface of the B.B. shell

8. Install drive side outer seal ring.

Outer Seal Ring

BBSP104

Apply grease to the external faces of the

bearings before installing the outer seal rings

6. Install non-drive side outer seal ring.

7. GXP conversion only.

If using a GXP style crankset, press the

second half of the GXP conversion

(BBSP109 - available separately) into

the OUTER face of the non-drive side

bearing, trapping the outer seal.

Hope Bottom Bracket Tool (HTTPFA)

can be used to install this outer GXP

conversion, but it must be done

before installing the drive side outer

seal ring.

Your bottom bracket is now fully installed and ready for the continued installation of your crank set.

*Only install BBSP109 if using a GXP crank set

Issue 01 - 03/2014

Outer Seal Ring

BBSP104

GXP Conversion

BBSP109*

Apply grease to the external faces of the bearing

before installing the outer seal ring

Hold this end stationary

using a 27mm spanner

Tighten the nut using a 19mm

spanner until the non-drive side

bearing is pulled fully into position

Non-drive side cup is installed

Centre tube is installed

Unscrew the nut and remove the tool

Non-drive side cup is now

fully flush with the BB shell

Non-drive side bearing is installed

Unscrew the nut and remove the tool

Non-drive side bearing is now fully

pressed into the non-drive side cup

Tightening torque:

27-34 Nm ( 20-25 ft. lbs. )