Hanna Instruments HI 96742 User Manual

Hanna Instruments Measuring instruments

INSTRUCTION MANUAL

HI 96742

HI 96742

HI 96742

HI 96742

HI 96742

Iron LR and

Manganese LR

ISM

w w w . h a n n a i n s t . c o m

Preliminary examination:

Please examine this product carefully. Make sure that the instrument is

not damaged. If any damage occured during shipment, please notify

your Dealer.

Each HI 96742 Ion Selective Meter is supplied complete with:

• Two Sample Cuvettes and Caps

• 9V Battery

• Instruction Manual

Note:

save all packing material until you are sure that the instrument

works correctly. Any defective item must be returned in its original

packing.

For more details about spare parts and accessories

see “Accessories”.

Dear Customer,

Thank you for choosing a Hanna product. This manual will provide you

with the necessary information for the correct use of the instrument. Please

read it carefully before using the meter. If you need additional technical

information, do not hesitate to e-mail us at [email protected].

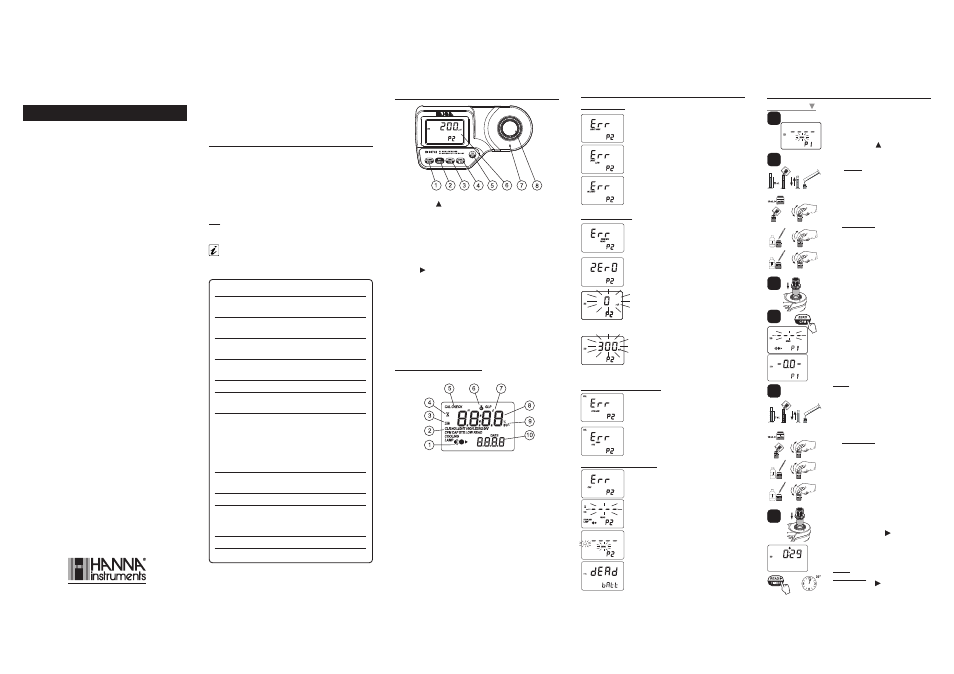

1. RANGE/GLP/ key: press to change the paramter, press and hold

for three seconds to enter

GLP mode. In calibration mode press to edit

the date and time.

2. CAL CHECK key: press to perform the validation of the meter, or

press and hold for three seconds to enter

calibration mode.

3. ZERO/CFM key: press to zero the meter prior to measurement, to

confirm edited values or to confirm factory calibration restore.

4. READ/ /TIMER key: In

measurement mode, press to make a

measurement, or press and hold for three seconds to start a

pre-programmed countdown prior to measurement. In

GLP mode

press to view the next screen.

5. ON/OFF key: to turn the meter on and off.

6. Liquid Crystal Display (LCD)

7. Cuvette alignment indicator

8. Cuvette holder

DISPLAY ELEMENTS DESCRIPTION:

Functional description:

1. The measuring scheme (lamp, cuvette, detector), appears during

different phases of zero or reading measurement

2. Error messages and warnings

3. The battery icon indicates the charge state of the battery

4. The hourglass appears when an internal check is in progress

5. Status messages

6. The chronometer appears when the reaction timer is running

7. The month, day and date icons appear when a date is displayed

8. Four digit main display

9. Measuring units

10. Four digit secondary display

Light High:

There is too much light to perform

a measurement. Please check the preparation of

the zero cuvette.

Light Low:

There is not enough light to perform

a measurement. Please check the preparation of

the zero cuvette.

No Light:

The instrument cannot adjust the

light level. Please check that the sample does

not contain any debris.

Errors and warnings:

ON ZERO READING:

ON SAMPLE READING:

DURING CALIBRATION PROCEDURE:

OTHER ERRORS AND WARNINGS:

Cap error:

Appears when external light enters

in the analysis cell. Assure that the cuvette cap

is present.

Cooling lamp:

The instrument waits for the

lamp to cool down.

Battery low:

The battery must be replaced

soon.

Dead battery:

This indicates that the battery

is dead and must be replaced. Once this

indication is displayed, normal operation of the

instrument will be interrupted. Change the

battery and restart the meter.

Standard Low:

The standard reading is less

than expected.

Standard High:

The standard reading is higher

than expected.

Inverted cuvettes:

The sample and the zero

cuvette are inverted.

Zero:

A zero reading was not taken. Follow the

instructions of the measurement procedure for

zeroing the meter.

Under range:

A blinking “0.00” indicates that

the sample absorbs less light than the zero

reference. Check the procedure and make sure

you use the same cuvette for reference (zero)

and measurement.

Over Range:

A flashing value of the maximum

concentration indicates an over range condition.

The concentration of the sample is beyond the

programmed range: dilute the sample and

re-run the test.

1• Turn the meter on by pressing ON/OFF.

2• When the beeper sounds briefly and the LCD

displays dashes and “P1” (Iron LR) and “P2”

(Manganese LR) the meter is ready. The code

that appears on the secondary display is the

one of the last selected parameter. If necessary,

press RANGE/GLP/ to change parameter.

The blinking “ZERO” indicates that the

instrument needs to be zeroed first.

3• For Iron LR: Fill one graduated mixing

cylinder up to the 25 mL mark with

deionized water. Add the content of one

packet of HI 93746-0 reagent, close the

cylinder and shake well for 30 seconds. This

is the blank.

Fill a cuvette with 10 mL of the blank up to

the mark and replace the cap.

For Manganese LR: Fill one cuvette with 10

mL of deionized water up to the mark. Add

the content of one packet of HI 93748A-0

Ascorbic acid, replace the cap and shake

gently until completely dissolved. Add 0.2

mL of the HI 93748B-0 Alkaline-cyanide

reagent solution, replace the cap and invert

gently to mix for about 30 seconds. Add 1

mL of the HI 93748C-0 0.1% PAN indicator

solution, replace the cap and shake gently.

4• Place the cuvette into the holder and ensure

that the notch on the cap is positioned

securely into the groove.

5• Press ZERO/CFM and the lamp, cuvette and

detector icons will appear on the display,

depending on the measurement phase.

6• After a few seconds the display will show “-

0.0-”

. The meter is now zeroed and ready

for measurement.

7• Remove the cuvette.

8• Add the specific test reagent for each

parameter:

Iron LR: Fill one graduated mixing cylinder

up to the 25 mL mark with the sample.

Add the content of one packet of HI 93746-0

reagent, close the cylinder and shake well

for 30 seconds.

Fill a cuvette with 10 mL of the reacted

sample up to the mark and replace the

cap.

For Manganese LR: Fill one cuvette with 10

mL of sample up to the mark. Add the

content of one packet of HI 93748A-0

Ascorbic acid, replace the cap and shake

gently until completely dissolved. Add 0.2

mL of the HI 93748B-0 Alkaline-cyanide

reagent solution, replace the cap and invert

gently to mix for about 30 seconds. Add 1

mL of the HI 93748C-0 0.1% PAN indicator

solution, replace the cap and shake gently.

9• Replace the cuvette into the holder and

ensure that the notch on the cap is

positioned securely into the groove.

10•Press and hold READ/ /TIMER for three

seconds

.

The display will show the countdown

prior to measurement. The beeper is playing

a beep at the end of countdown period.

Alternatively, wait for:

Iron LR:

30 seconds

Manganese LR: 2 minutes

Then press READ/ /TIMER.

9-10

Measurement procedure:

Measurement

2

5-6

or

3

Technical specifications:

Range

Iron LR

0.00 to 1.60 mg/L

Manganese LR

0 to 300 µ/L

Resolution

0.01 mg/L Iron LR

1 µg/L Manganese LR

Accuracy

Iron LR

±0.01 mg/L ±8% of reading @ 25°C

Manganese LR ±2 µg/L ±3% of reading @ 25°C

Typical EMC Dev.

±0.01 mg/L Iron LR

±1 µg/L Manganese LR

Light Source

Tungsten lamp

Light Detector

Silicon Photocell with narrow band interference

filter @ 525 nm

Method

For Iron LR: Adaptation of the TPTZ method. The reaction

between iron and the reagent causes a violet tint in the

sample.

For Manganese LR: Adaptation of the PAN Method. The

reaction between manganese and the reagents causes an

orange tint in the sample.

Environment

0 to 50°C (32 to 122°F);

max 95% RH non-condensing

Battery Type

1 x 9 volt

Auto-Shut off

After 10' of non-use in measurement mode;

after 1 hour of non-use in calibration mode;

with last reading reminder.

Dimensions

192 x 104 x 69 mm (7.6 x 4.1 x 2.7”)

Weight

360 g (12.7 oz.).

4

5-6

8