1 general, 9 safety valve, 4 gas supply – Glow-worm Micron 40FF User Manual

Page 5: 5 electrical supply, 6 contents of packaging, 8 water system, 8 draining tap

5

221911E

1.9 Safety Valve

A safety valve need not be fitted to an open vented system.

1 General

1.4 Gas Supply

The gas installation shall be in accordance with the relevant

standards.

In GB this is BS6891.

In IE this is the current edition of I.S.813 "Domestic Gas

Installations".

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg)

at the boiler.

On completion test the gas installation for soundness using the

pressure drop method, purge in accordance with the above

standard.

1.5 Electrical Supply

WARNING: This boiler must be earthed.

All system components shall be of an approved type and shall

be connected in accordance with the current issue of BS7671

and any applicable local regulations.

External wiring must be correctly earthed, polarised and in

accordance with the relevant standards.

In GB this is BS 6891.

In IE this is the current edition of I.S.813 "Domestic Gas

Installations".

Connection of the boiler and system controls to the mains

supply must be through a common isolator and must be fused

3A, maximum. This method of connection must be by a fused

double pole isolating switch, with a minimum contact separation

of 3mm on both poles. The switch should be readily accessible

and preferably adjacent to the appliance. It should supply the

appliance only and be easily identifiable as so doing.

Alternatively, an unswitched shuttered socket outlet and 3A

fused 3 pin plug, both to the current issue of BS1363 may be

used provided that they are not used in a room containing a bath

or shower.

Wiring to the boiler must be PVC 85

0

C insulated cable, not less

than 0.75mm

2

(24/0.20mm).

1.6 Contents of Packaging

The boiler is delivered in one pack with the flue system packed

separately.

1.8 Water System

This boiler may be fitted to an open vented or a sealed water

system.

1.8 Draining Tap

System

A draining tap must be provided at the lowest points of the

system which will allow the entire system and hot water cylinder

to be drained.

Draining taps should be to the current issue of BS2879.

Boiler

A draining point is fitted at the bottom right hand side of the heat

exchanger.

When draining is required cover the controls to avoid water

damage.

If required remove the combustion chamber front cover to

improve access.

9441

PMS = 3.0 bar, is: Maximum water-side operating pressure.

The appliance flue type is a C

12

, C

22

, C

32

and C

52

. This refers to a

concentric or twin flue where the fan is downstream of the heat

exchanger. The C

12

is a horizontal flue termination, the C

22

is a

shared duct system (Seduct), the C

32

is a vertical flue termination and

the C

52

has separate ducts to two terminals that may terminate in

zones of different pressure.

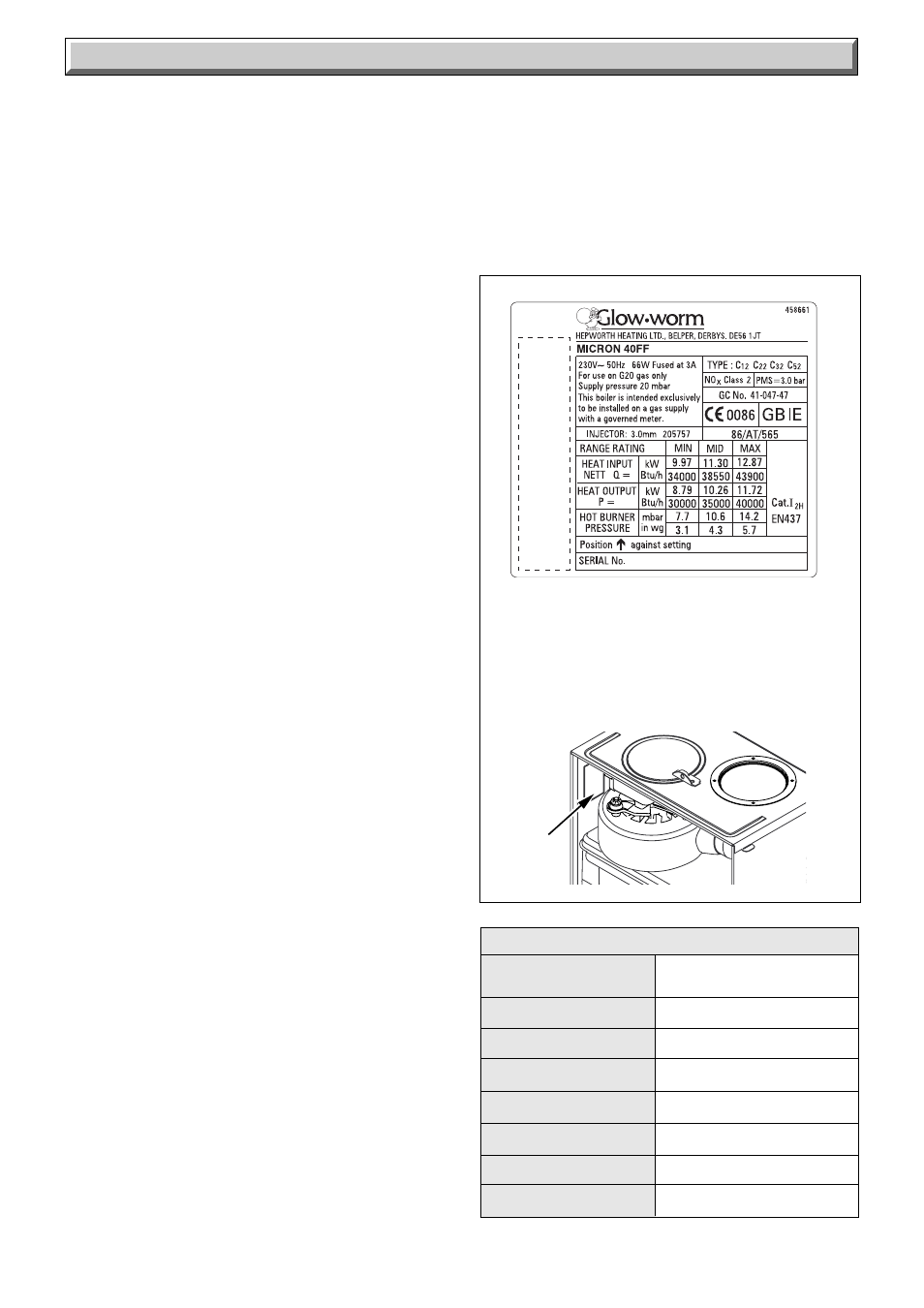

DATA

LABEL

7316

Diagram 1.2

TABLE 1.

TOTAL DRY WEIGHT

(Including Terminal)

LIFT WEIGHT

WATER CONTENT

GAS CONNECTION

ELECTRICITY RATING

WATER CONNECTION

ELECTRICITY SUPPLY

DATA LABEL

36.4 kg (80lb)

29.7 kg (65.34lb)

2.2 litre (0.48 gallon)

66W Internal fuse Type T3.15A

2x22mm copper pipes from

back of case

230V~50Hz,fused 3A

Top left hand inside of case

Rc

1

/

2

in.