8 servicing – Glow-worm Micron 40FF User Manual

Page 20

20

221911E

Diagram 8.4

COMBUSTION

CHAMBER

COVER

7226

SCREW

BURNER

RETAINING

SCREW

BURNER

SCREW

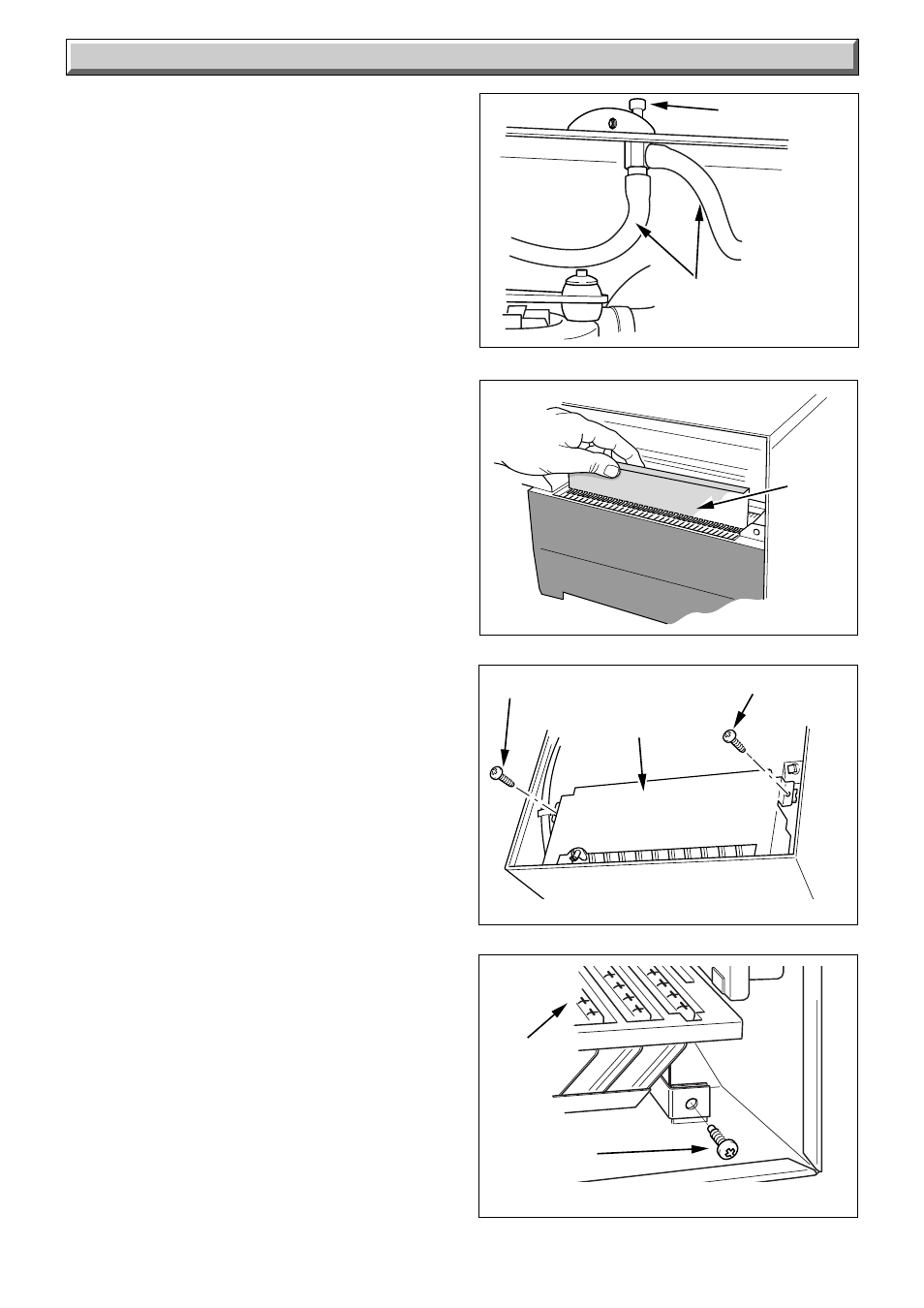

Diagram 8.3

6778

8 Servicing

Diagram 8.2

BAFFLE

(6 off)

6779

REMEMBER: When replacing a part on this appliance, use

only spare parts that you can be assured conform to the safety

and performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised

by Glow-worm.

Products of Combustion Check

NOTE: To obtain a products of combustion reading, remove the

cap from the sampling point, located on top of the inner casing,

see diagram 8.1.

Connect the analyser tube onto the nipple.

Switch on the electrical supply and gas supply then operate the

boiler.

On completion of the test switch off the electrical supply and the

gas supply, remove analyser tube and replace sampling point

cap.

Servicing

Before servicing turn off the gas and isolate the electrical supply

to the boiler.

After completing a service always test for gas soundness, make

electrical checks and carry out functional check on controls.

Unless stated otherwise all parts are replaced in the reverse

order to removal.

8.1 Access

Remove the boiler case, see diagram 5.1 and Section 5.2.

8.2 Burner

Remove front combustion chamber cover which is secured by

two screws, see diagram 8.3.

Pull back electrode protection sleeve and disconnect electrode

connection along with earth connection, see diagram 8.6.

Remove the burner retaining screw located at the right hand

side of the burner, see diagram 8.4.

When completed, take hold of burner and slide it to the left

clearing the injector and remove. Take care not to damage the

combustion chamber insulation

Use a vacuum cleaner or suitable stiff brush (not wire) to clean

the burner thoroughly, making sure that all the burner ports are

clear and unobstructed.

On refitting and after cleaning the heat exchanger make sure

the burner is fitted correctly, that is, located on the injector and

horizontal.

NOTE: It is advisable while servicing the burner to check the

combustion chamber insulation and replace if damaged, see

Section 10.10.

8.3 Cleaning Heat Exchanger Flueways

Disconnect the air pressure switch tube connection, both clear

tubes from test nipple, see diagram 8.1.

Remove the blue and purple electrical connections from the fan

see diagram 5.5.

If top outlet installation: Remove air deflector, or it may just be

swung back by loosening the wing-nuts, to enable fan assembly

to be removed, see diagram 8.7 and Section 5.3.

Remove the fan assembly complete with the flue elbow, see

diagram 5.5 and Section 5.3

Place a sheet of paper in the base of the combustion chamber

and over the injector to prevent particles entering.

Remove the baffles, see diagram 8.2.

Diagram 8.1

CLEAR AIR

PRESSURE TUBES

SAMPLING

POINT

7231