1 general – Glow-worm Inset BBU50 User Manual

Page 5

5

221723B

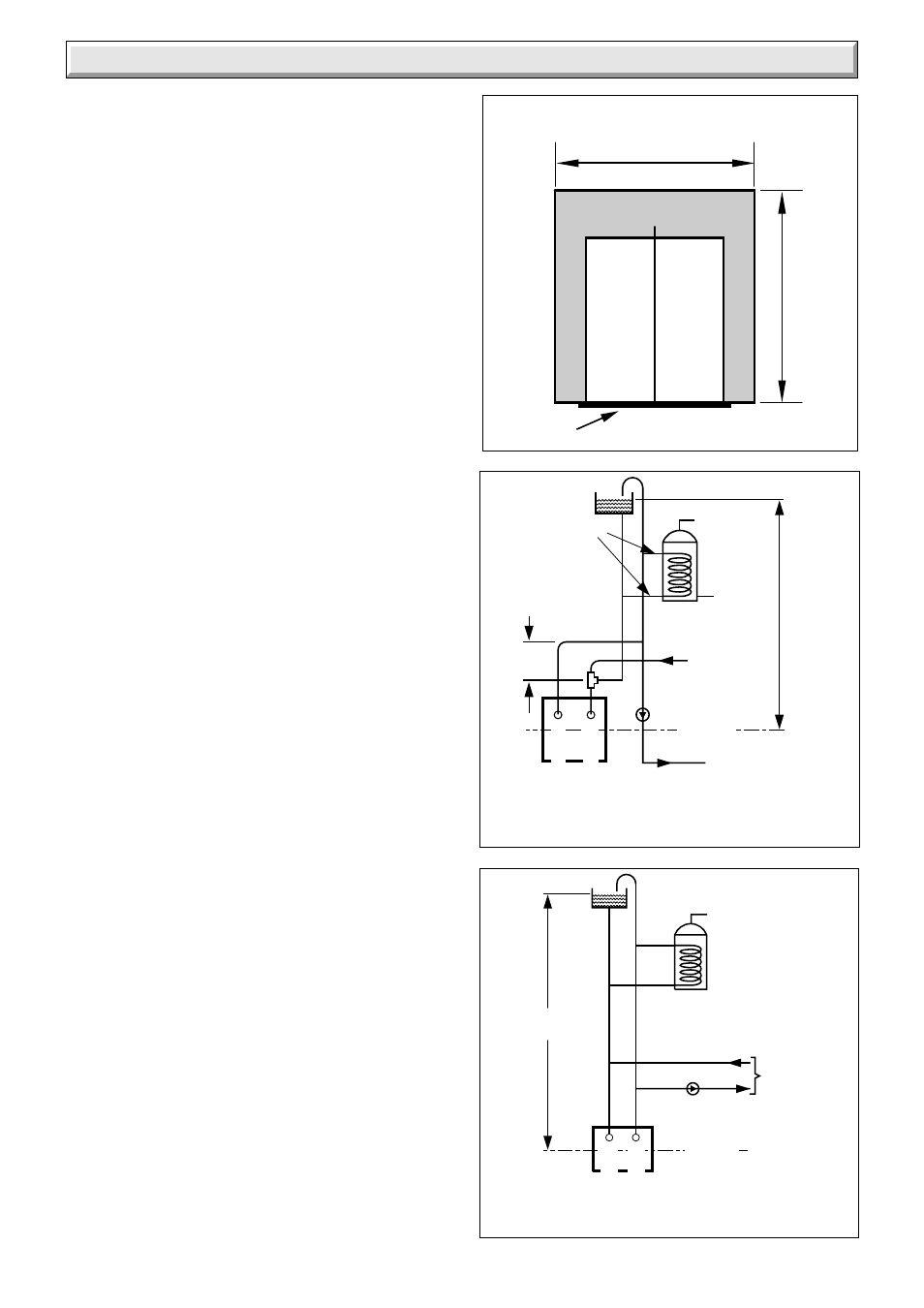

Diagram 1.4

Diagram 1.5

6242

6243

BOILER

22mm

CENTRAL

HEATING

RETURN

28mm

DISTRIBUTOR

TUBE IN RETURN

CONNECTION

22mm

CENTRAL

HEATING

FLOW

FLOW

RETURN

INDIRECT

CYLINDER

27 METRES

MAXIMUM

FIXED

DIMENSION

C

L

INDIRECT

CYLINDER

PUMP

TO HEATING

CIRCUIT

1 METRE MIN

27 METRE MAX

RETURN

FLO

W

BOILER

C

L

PUMPED HEATING & GRAVITY DOMESTIC HOT

WATER (DIAGRAMMATIC)

FULLY PUMPED SYSTEM

(DIAGRAMMATIC)

1.5 Contents of Packaging

The boiler is delivered in one pack which contains all the parts

required for installation.

1.6 Site Requirements

For all types of installation a standard 16inch builder’s opening

is required, see diagram 1.2.

Note: The depth of the fire opening is IMPORTANT, it MUST

therefore conform to the dimensions given in diagram 1.2.

Any larger opening will need to be reduced, with non-combustible

material to conform to this requirement.

It is important that the opening is cleared of debris and mortar

etc.

The prepared base for the back boiler must be level.

Refer to diagram 1.3 for dimensions of the fire fixing wall face

which MUST be true.

1.7 Water System - Open Vented

This boiler can be used on an unrestricted open vented system

with the water supply taken from a feed and expansion cistern,

having a head between 1m (3ft 3in) minimum and 27m (90ft)

maximum.

Diagrammatic layouts of systems are shown in diagram 1.4 and

1.5.

Sealed Water System

A Kit and instructions, Part No. 459033, is available to enable

the back boiler to be used on a sealed water system.

Please give the serial number of the back boiler unit when

ordering the kit.

1.8 Hot Water Cylinder

The back boiler is suitable for open vented systems using an

indirect cylinder (including single feed self priming type). The

cylinder must be fitted to the manufacturer’s recommendations

and the system must conform to the requirements of the current

issue of BS5449.

It is recommended that the cylinder be fitted with some form of

temperature control.

1.9 Frost Protection

If the position of the boiler is such that it may be vulnerable to

freezing it should be protected as specified in the current issue

of BS5422.

It is also recommended that a frost thermostat is fitted.

1.10 Draining Tap

A draining tap must be provided at the lowest point of the system

which will allow the entire system, the boiler and hot water

cylinder to be drained.

Draining taps shall be to the current issue of BS2879.

1.11 Safety Valve

A safety valve need not be fitted to an open vented system.

1.12 Boiler Location

This back boiler unit MUST NOT be installed in a private garage

or in a room containing a bath or shower or a room used or

intended to be used as sleeping accommodation.

1 General

Diagram 1.3

C

L

5506

690

Minimum flat area and fixture or

surround protection clearance

PREPARED BASE

800 MIN WIDE FRAME

780 MIN STANDARD FRAME