2 water systems – Glow-worm Hideaway 80CFF User Manual

Page 8

8

2000225006B

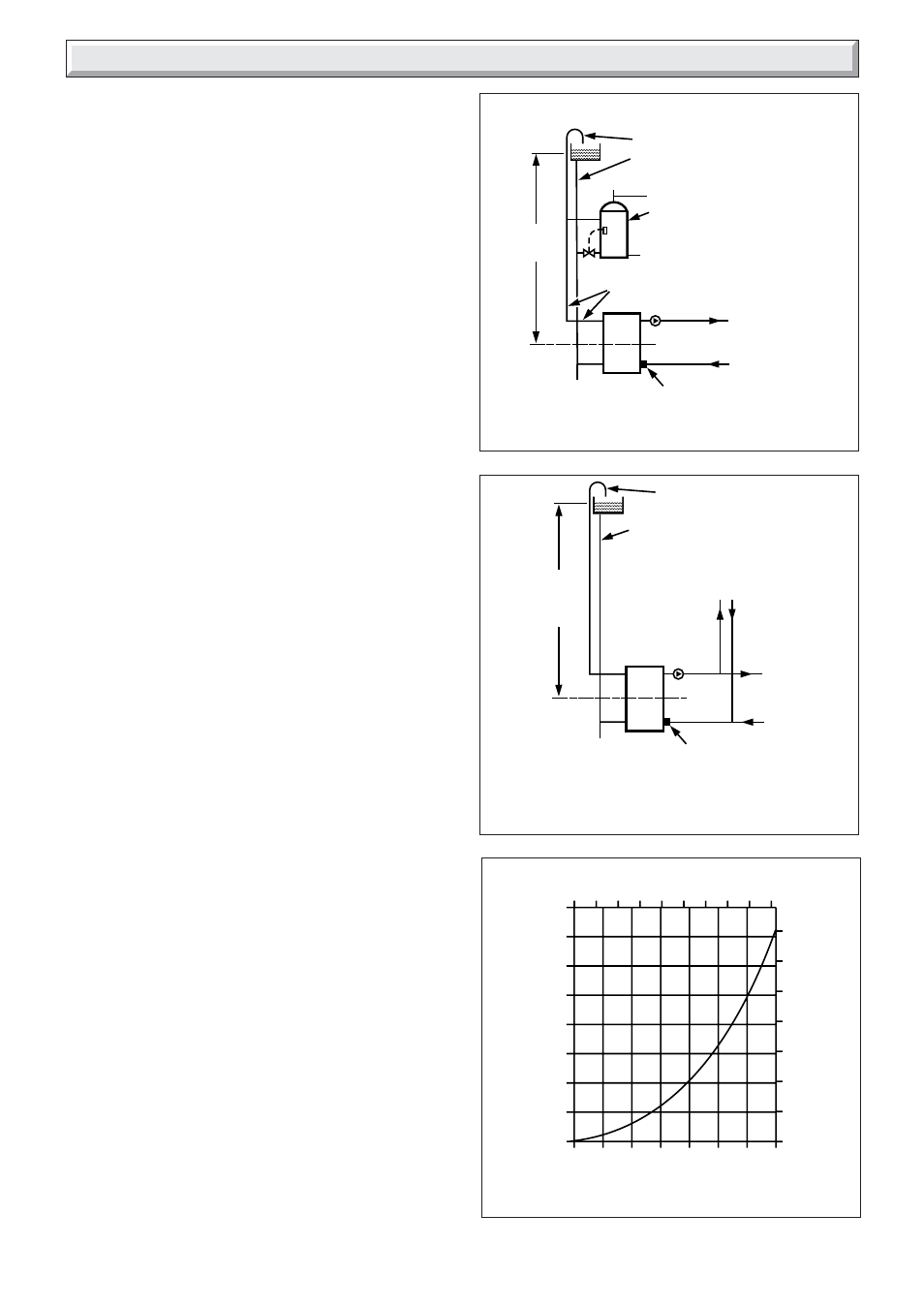

Diagram 2.2

FULLY PUMPED SYSTEM

(DIAGRAMMATIC)

2 Water Systems

0870

1 metre

MIN.

27metres

MAX.

PUMP

Heating

Circuit

TO INDIRECT

CYLINDER

22mm VENT

15mm

COLD FEED

Distributor tube in

pumped return

connection

BOILER

CL

DRAIN OFF

COCK

2.1 Water Pressure Head

The boiler shall only be connected to a cistern water supply with

a minimum head of 1metre (3ft3in) and a maximum head of

27metres (90ft) which has an open vent in the system.

The working pressure must be within the range 0.1bar to 2.7bar

(1.3 to 39lbftin

2

).

The boiler MUST NOT be connected to a sealed water system.

2.2 Inhibitor

Attention is drawn to the current issue of BS5449 and BS7593

on the use of inhibitors in central heating systems.

If an inhibitor is to be used in the system, contact should be

made with the inhibitor manufacturers so that they can

recommend their most suitable product.

When using in an existing system take special care to drain the

entire system, including the radiators, then thoroughly clean out

before fitting the boiler whether or not adding an inhibitor.

2.3 Gravity Domestic and Pumped Heating

It is recommended that a cylinder thermostat is used to prevent

the stored water temperature becoming unnecessarily high

when the central heating pump is off.

The domestic primary flow and return must be 28mm o.d. The

installation must comply with the current issue of BS5546 and

BS6700, see diagram 2.1.

If the above conditions cannot be met, it is suggested that a fully

pumped system be used.

2.4 Pumped Heating and Hot Water

Where a single flow and return is taken from the boiler, a

minimum static head of 1metre (3ft3in) must be provided

between the water line of the feed tank and the centre of the

waterway, see diagram 2.2.

2.5 Circulation Pump

Normally the pump should be set to give a temperature difference

of 11

o

C (20

o

F) across the boiler. At the appropriate pumped flow

rate the pressure loss through the boiler can be found from the

graph, diagram 2.3.

Use a pump with integral valves or fit isolating valves as close

to the pump as possible.

2.6. Cylinder

For all systems supplying domestic hot water the cylinder must

be indirect.

2.7 Safety Valve

A safety valve need not be fitted to an open vented system.

2.8 Draining Tap

A draining tap must be provided at the lowest points of the

system which will allow the draining of the entire system,

including the boiler and hot water cylinder.

Draining taps should be to the current issue of BS2879.

2.9 Thermostatic Radiator Valves

If thermostatic radiator valves are fitted care must be taken to

ensure that there is an adequate flow rate through the boiler

when they close, refer to the current issue of BS7478 for

guidance. If fitted to all radiators ensure a bypass is fitted and

adjust to achieve a temperature difference no greater than 20

o

C

between flow and return with the thermostatic valves closed.

Diagram 2.3

1.50

1.25

1.00

0.75

0.50

0.25

0

30

20

10

0

0

6

12

18

24

30

36

42

FLOW RATE (LITRES/MINUTE)

WATER PRESSURE LOSS

(metre HEAD OF WATER)

WATER PRESSURE LOSS

(INCHES HEAD OF WATER)

60

40

2.00

70

50

1.75

0

1

2

3

4

5

6

7

8

9

FLOW RATE (GALLON/MINUTE)

1074

Diagram 2.1

0869

27metres

Max.

PUMP

Heating

Circuit

INDIRECT

CYLINDER

(Shown with

recommended

thermostat and valve).

22mm VENT

15mm COLD FEED

REFER TO BS 5546

28mm

Distributor tube in

pumped return

connection

ILER

CL

DRAIN OFF

COCK