1 general – Glow-worm 45/2 Back Boiler User Manual

Page 3

3

221780A

1 General

RANGE RATING

NOMINAL

kW

HEAT INPUT

(GROSS)

Btu/h

NOMINAL

kW

HEAT

OUTPUT

Btu/h

BURNER

mbar

SETTING

PRESSURE

in.w.g

12.9

15.4

17.8

44,100

52,500

60,900

3.3 FF2022

9.5

11.7

13.7

32,450

39,800

46,750

8

11.4

15.2

3.21

4.54

6.10

INJECTOR

MARKING

Minimum Medium

Maximum

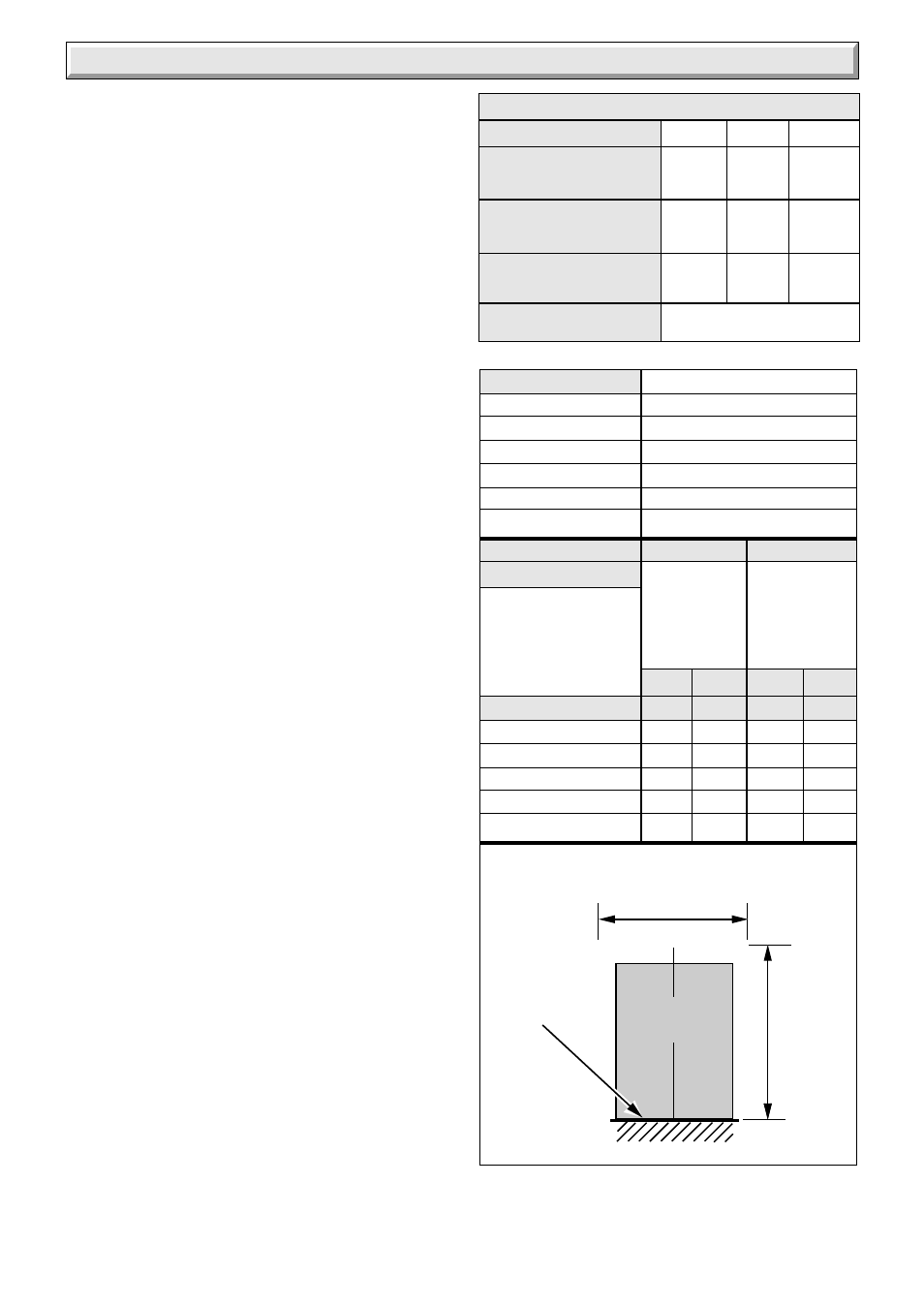

RANGE RATING TABLE

1.2 Data

Gas connection

Rc

1

/

2

(

1

/

2

inBSPT)

Water connection

Rc1 (1inBSPT)

Electrical supply

230V~50Hz fused 3A

Weight, about

42.5kg (93.7lb)

Water content

5.6Litres (1.23gall)

Injector

3.3mm

Dimensions are given in millimetres (except as noted).

Data Label: Bottom left of control tray.

1.3 Gas Supply

The gas installation shall be in accordance with the current issue

of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the back boiler.

On completion test the gas installation using the pressure drop

method and suitable leak detection fluid, purge in accordance

with the current issue of BS6891.

1.4 Electrical Supply

WARNING. This back boiler must be earthed.

All system components shall be of an approved type and shall

be connected in accordance with the current issue of BS7671

and any applicable local regulations.

Connection of the back boiler and system controls to the mains

supply should be through a double pole isolating switch, fused

3A having a minimum contact separation of 3mm in both poles.

Alternatively, a fused 3A 3 pin plug and unswitched socket outlet

to the current issue of BS1363 may be used.

Wiring to the back boiler must be PVC (85

o

C) insulated type to

the current issue of BS6500 Table 16, not less than 0.75mm

2

(24/0.20mm).

1.5 Site Requirements

Refer to diagram 1.1 for dimensions appropriate to the back

boiler.

For all types of installation a standard sized builder’s opening is

required, see diagram 1.2.

It is important that the opening is cleared of debris and mortar.

It is recommended that the access hole for pipework into the

fireplace or builder’s opening is either at the left hand or right

hand side of the chimney breast. If access is required at both

sides then it may be necessary to prepare some of the

connections before fitting the back boiler into the builder’s

opening.

The prepared base for the back boiler must be level.

Refer to Table 2 for dimensions of fire front fixing wall face which

must be true.

1.6 Water System - Open Vented

This back boiler can be used on an unrestricted open vented

system with the water supply taken from a feed and expansion

cistern, having a head between 1m (3ft3in) minimum and 27m

(90ft) maximum.

Diagrammatic layouts of systems are shown in diagram 1.3 and

1.4.

Dimensions

for

minimum

flat area

(no fixtures)

Dimensions

for fixture or

surround

protection

clearance

3013

FRONT

OPENING

CL

ALL DIMENSIONS IN MM

PREPARED

BASE

Y

X

G.C No.

Teak

Mahogany

T a b l e 1

FIRE TYPE

Miami 3 BBU

37-047-04A 37-047-07A

Melody 3 BBU

37-047-06A

Black Ash 3

37-047-08

Saxony 3

37-047-09

Brown Ember 3

37-047-02

T a b l e 2

FIRE

TYPE

X

Y

X

Y

Miami 3 BBU

642

698

750

836

Melody 3 BBU

642

698

750

836

Black Ash 3

700

660

840

890

Brown Ember 3

795

707

905

892

Saxony 3

700

625

840

860