12 servicing, Attention! 12. 6 combustion check – Glow-worm cxi and Gas Valve User Manual

Page 34

34

0020013349-02

Diagram 12.8

9183

DOMESTIC

COLD WATER

INLET FILTER

HOUSING

SECURING

CLIP

PUMP

12 Servicing

If a gas carrying component has been replaced, the combustion

of the appliance should be checked as follows. Once the

appliance has been re-assembled (apart from the front and

inner casing panels) connect a CO

2

combustion analyser to the

test

point on the flue adapter, see diagram 12.1.

Turn on the gas service cock, see diagram 7.1.

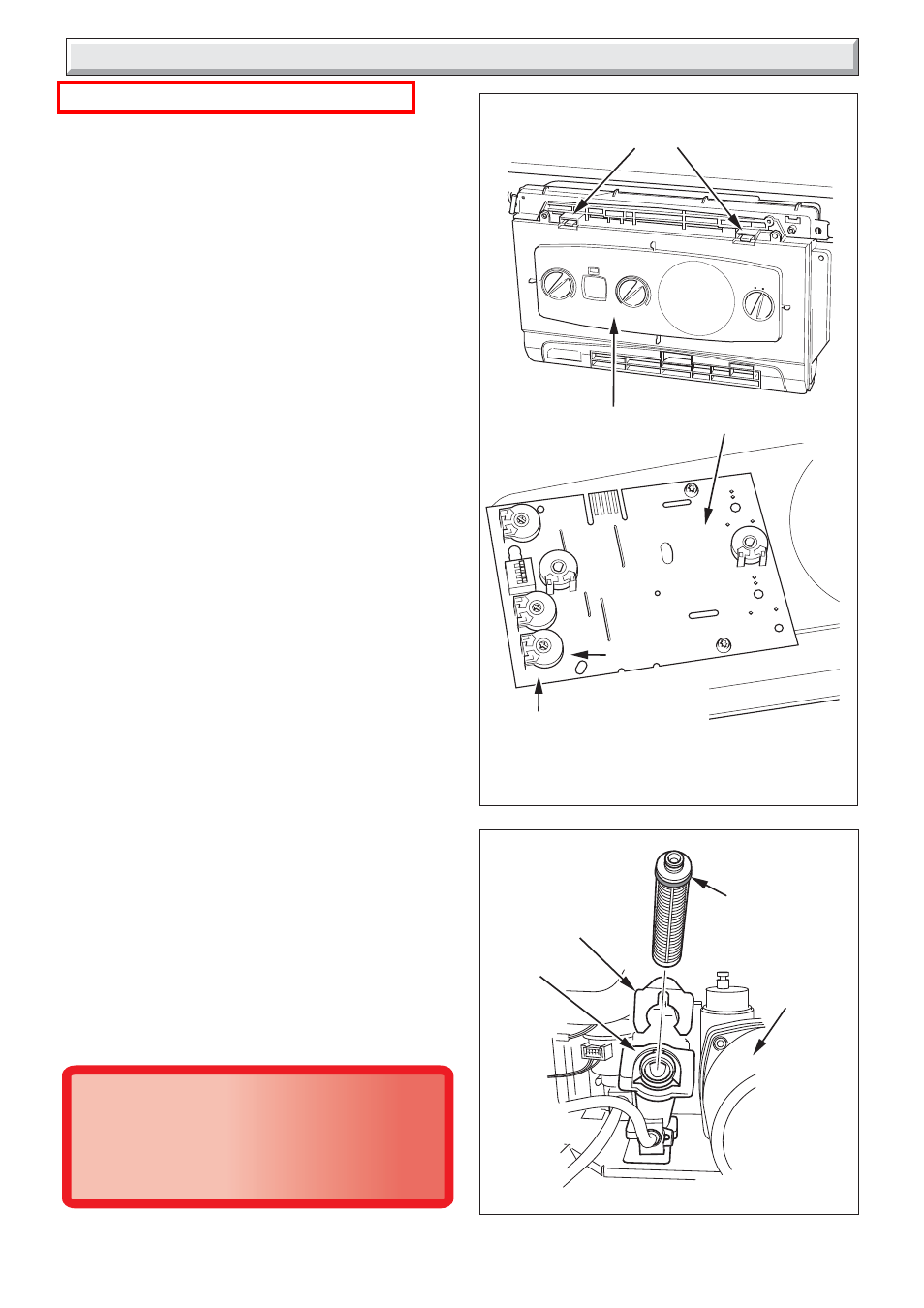

With the power off and the appliance cold, unclip the controls

fascia and hinge it down to reveal the potentiometers on the rear

of the User interface, see diagram 12.7. Take care not to allow

the fascia to drop down and damage the wiring.

Turn on the electrical supply.

Ensure external controls are calling for heat. The boiler should

fire automatically.

Allow the boiler to fire for a minimum of 60 seconds and then,

using an electrical screwdriver, rotate the service potentiometer

fully clockwise, see diagram 12.7. This will allow the digital

display to indicate the 'flashing' fan speed on the appliance

fascia.

In the fully clockwise position the display should be indicating

the maximum fan speed of the appliance, in central heating

mode this should be 39±1 for 24cxi, 45±1 for 30cxi and 45±1 for

38cxi. With domestic hot water max. demand this should be

51±1 for 24cxi, 57±1 for 30cxi and 57±1 for 38cxi. Check the

CO

2

value, which should be 9.1% +0.2 -0.5.

Note that with the inner casing panel fitted the combustion

readings will increase slightly to 9.3% +0.3 -0.5.

If adjustment proves necessary then proceed as follows.

Any adjustment to the gas valve should only be carried out by

a competent person.

Refer to diagram 11.4.

Adjust the maximum rate CO

2

with the throttle to 9.1%. (Rotate

anti-clockwise to increase).

Rotate the service potentiometer fully anti-clockwise. Hold it in

this position for about 5 seconds before rotating the service

potentiometer clockwise to the mid-point or 3 o'clock position.

The fan should reduce to 1200 ± 100 rpm which will flash '12' ±1

on the digital display.

Check the CO

2

value, which should be 9.1% +0.2 -0.5.

For Propane the CO

2

value, should be 10.5% +0.3 -0.7.

If adjustment proves necessary then proceed as follows.

Adjustment of the CO

2

at minimum rate is very coarse so

carefully adjust the CO

2

with the offset adjustment to 9.1%, see

diagram 11.4.

Rotate the service potentiometer fully clockwise, see diagram

12.7 and re-check the maximum rate combustion, which should

be 9.1% +0.2 -0.5.

After checking combustion rotate the service potentiometer

fully anti-clockwise so that the display indicates the water

temperature.

Replace the cap on the test point and refit the control cover rear

panel.

Diagram 12.7

MIN.

MAX.

POTENTIOMETERS

RETAINING

LATCHES

SERVICE

POTENTIOMETER

11472

11417

CONTROLS

FASCIA

USER INTERFACE