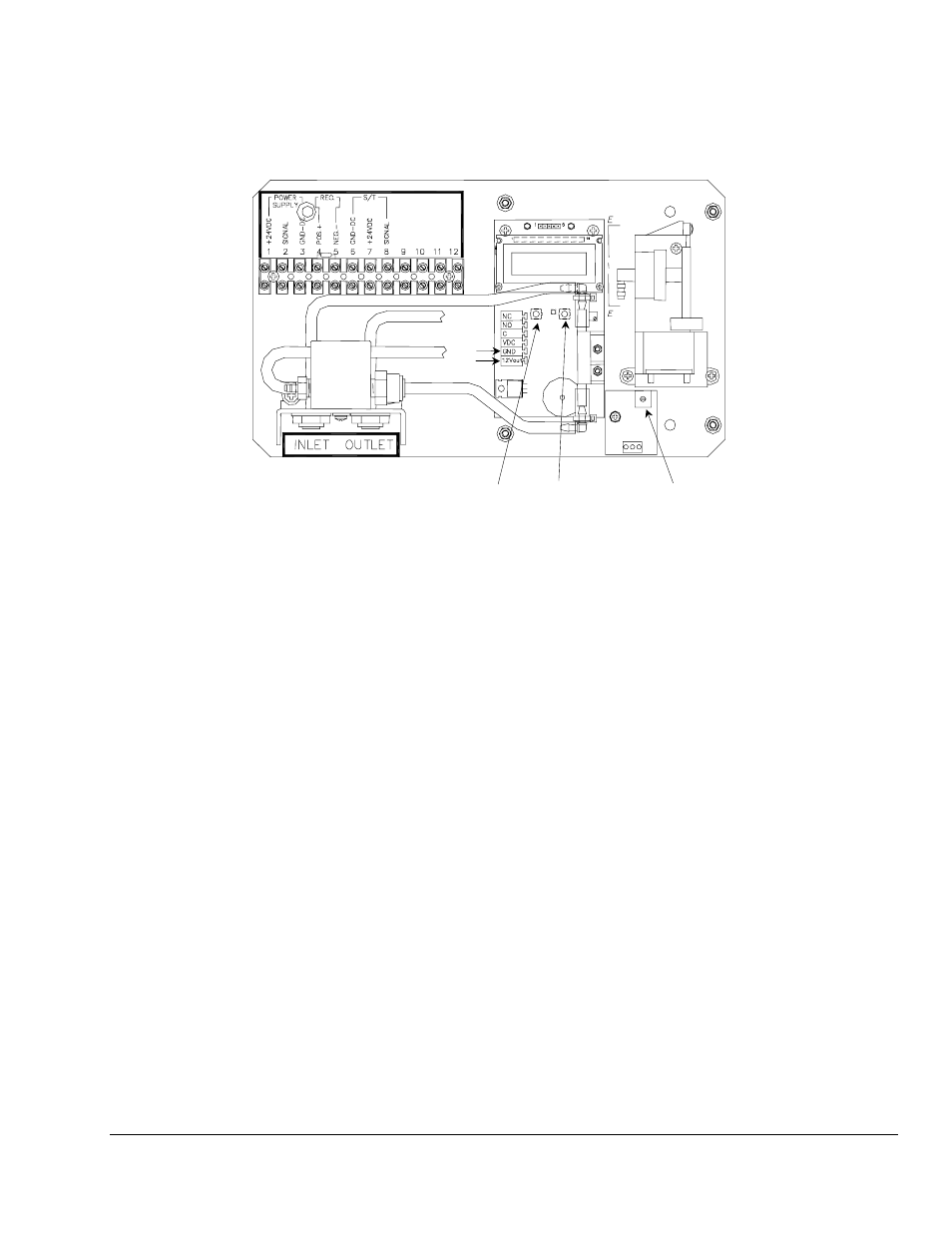

0 installation, Figure 2: interior view – ENMET GS-24-DF Gas Sampler User Manual

Page 7

3

Figure 2: Interior View

3.0 Installation

The GS-24-DF needs to be level and as close to the area to be monitored as possible, to reduce transport time to

the sensor/transmitter.

• Sensor/Transmitters can be located within the GS-24-DF or remotely.

• Inlet tubing must be compatible with the target gas.

Non reactive gases Standard vinyl or tygon tubing, ENMET part number 73073-001

Reactive gases

Teflon lined vinyl or tygon tubing, ENMET part number 73073-029

• Caution should be used to insure that fluids do not enter the inlet tubing.

• Some types of gases require that the sample gas be removed from the area.

This is accomplished with the outlet port.

• Power is supplied from an external source.

Connect 24 V

DC

to terminal block positions 1 and 3.

• Note 12Vdc output is available on the pump module.

• After installing all the tubing and the sensor/transmitter, verify that there are no leaks in the system.

Verification should be done by plugging the inlet tube.

If the system is correct the flow meter reads zero and the flow alarm activates.

If this does not happen, check all fittings and seals.

Display

Pump

Gas

Sensing

Chamber

SW1

M

ENU

Switch

SW2

S

ELECT

Switch

POT

Flow Adjust

Output