0 maintenance – ENMET Formaldemeter htV User Manual

Page 8

ENMET Corporation

Formaldemeter htV

6

5.0 Maintenance

W

ARNING

:

Please read this section thoroughly before attempting to check or adjust calibration. Users are strongly advised to

familiarize themselves with the instrument before attempting to adjust the calibration and should follow the instructions

carefully.

5.1 General Information

Check calibration regularly

Sensor sensitivity can change very gradually with time, periodic recalibration may be required. It is advisable to check

calibration regularly to ensure that the instrument is functioning correctly.

A quick calibration check can be carried out by drawing a formaldehyde vapor sample of known concentration into the

instrument’s sensor and noting whether the displayed reading agrees with the expected concentration value.

The

Formaldemeter

™

htV is supplied complete with a formaldehyde calibration standard and a thermometer, which are

essential components for checking and adjusting calibration.

5.2 The Formaldemeter

™

htV

Calibration Standard

The

Formaldemeter

™

htV Formaldehyde Calibration Standard consists of formaldehyde absorbed on a solid substrate in a

glass tube from which a headspace

vapor sample can be drawn. Each standard is carefully manufactured to a high tolerance.

5.2.1 Effect of temperature

The concentration of formaldehyde vapor generated in the calibration tube varies with temperature and for this reason, a

thermometer and temperature/concentration table is supplied.

Handle the calibration standard as little as possible, and only by the yellow end caps to avoid heating the

tube.

5.2.2 Temperature equilibration

Before using the standards, they should always be allowed to stabilize within the recommended temperature range of 15 – 29°C

for at least 1 hour.

5.2.3 Standard life

Each standard has a capacity for 100 samples or a life of six months (whichever occurs sooner) and it must not be used after the

indicated expiry date. New calibration standards can be ordered from your local distributor.

5.3 Calibration Check Procedure

5.3.1 Temperature equilibration

Place the instrument, thermometer and calibration standard together in a place where the temperature is stable for at least one

hour before commencing the calibration check procedure to allow thermal equilibration.

5.3.2 Sensor check

Before carrying out a calibration check, the sensor must be clear of formaldehyde vapor from any previous samples. When the

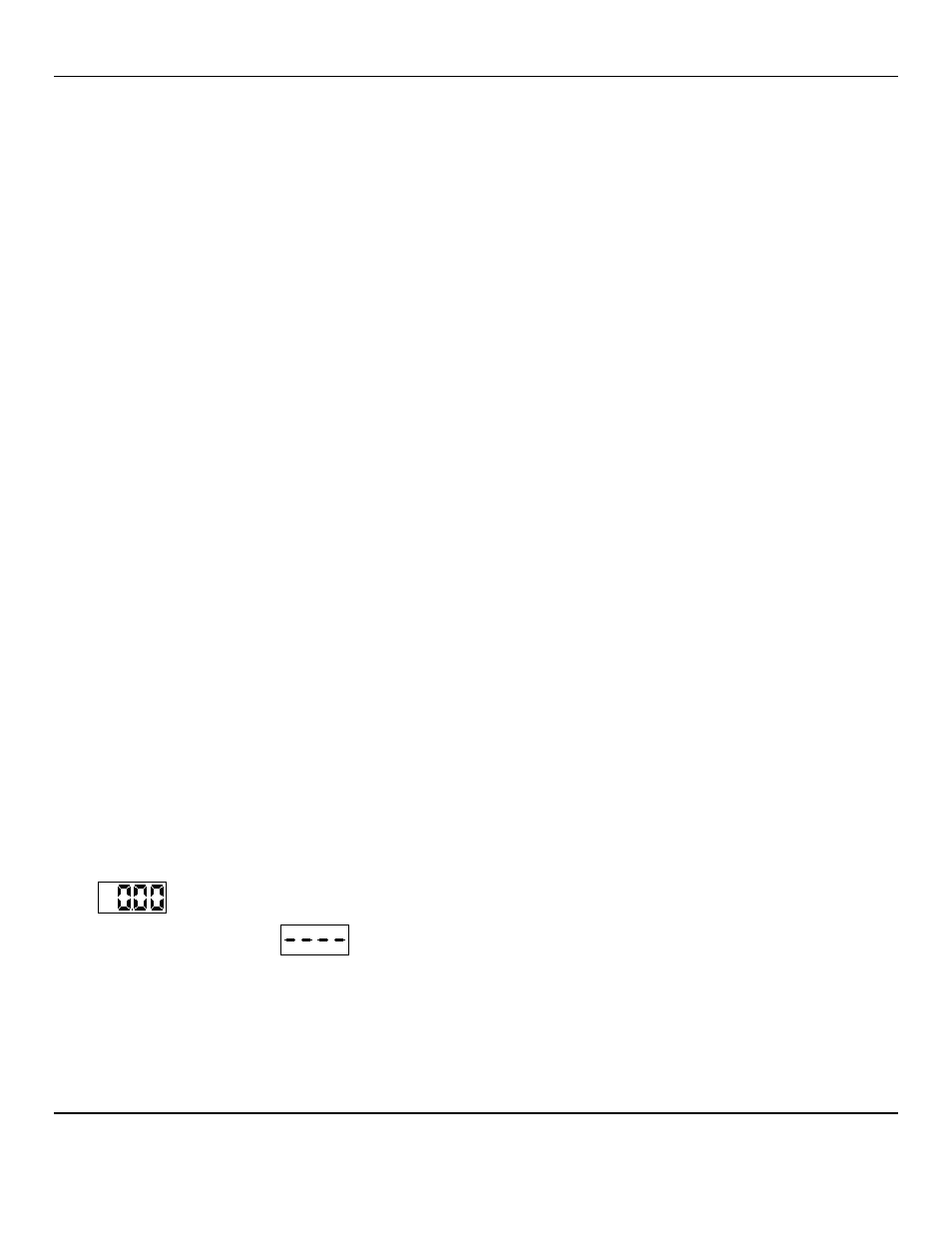

sensor is clear, the display will show:

3 seconds after power on.

If the display shows flashing

for longer than 5 seconds, then the sensor is not ready to take a sample. Switch the

instrument off and allow it to recover for a few minutes.