Minia ture radio transmitter, Circuit opera tion, High freq uency oscilla t o r – Elenco Whooper Alarm User Manual

Page 4: Constr uction, Figure 1 figure 2 figure 3

-4-

-3-

MINIA

TURE RADIO

TRANSMITTER

The

Whooper Alar

m puts out a w

a

v

e

ring sound that is sure to star

tle an

intr

uder

. It can be used independently or as an accessor

y

to the Burglar

Alar

m Kit K-23.

The

Whooper Alar

m circuit consists of tw

o oscillators

, a lo

w frequency

oscillator which dr

iv

es a higher frequency unit at a predeter

mined r

a

te

.

The high frequency oscillator dr

iv

es an output tr

ansistor which po

w

e

rs the

speak

er

.

CIRCUIT OPERA

TION

Figure 1 sho

w

s the circuits of the lo

w frequency oscillator

.

When the

po

w

e

r is first applied to this circuit, tr

ansistors Q1 and Q2 will not conduct.

This is because the base of tr

ansistor Q2 is about 5.4V while the emitter

is at z

e

ro v

olts

.

A current is flo

wing in resistor R2 charging capacitor C1.

When the v

oltage

across C1 reaches 6V

, tr

ansistor Q2 star

ts sending a current in the

collector of Q1.

The current in the collector of Q1 is m

ulitplied b

y

the gain

of tr

ansistor Q1 and this r

apidly tur

n

s on tr

ansistor Q2.

Capacitor C1

quic

kly discharges through resistor R8 as sho

wn in Figure 2.

Note that C1

charges through a 2200

Ω

resistor R2, b

u

t discharges through a 100

Ω

resistor R8.

Thus

, the charge to discharge r

a

tio is 22:1.

When C1 is

discharged, Q1 and Q2 tur

n

off and the whole cycle repeats itself

.

HIGH FREQ

UENCY OSCILLA

T

O

R

The circuit of the high frequency oscillator is sho

wn in Figure 3.

T

ransistors Q3 and Q4 are wired as amplifier stages

.

The bias f

o

r these

amplifiers are controlled b

y

the sa

wtooth of Figure 2.

These amplifiers

nor

mally w

ould amplify the lo

w frequency pulses

, e

xcept f

o

r the addition of

capacitor C3.

This capacitor tak

e

s the output of Q4 and f

eeds it in phase

to the input of Q3.

This causes the circuit to oscillate

.

The frequency of

oscillation is controlled b

y

the RC time constants of C3 and R6.

The

frequency of oscillation is about 1,000 cycles per second.

This frequency

is modulated with the lo

w frequency oscillations to produce the

Whooper

Alar

m sounds

.

T

ransistor Q5 fur

ther amplifies the signals and dr

iv

es the

speak

er

.

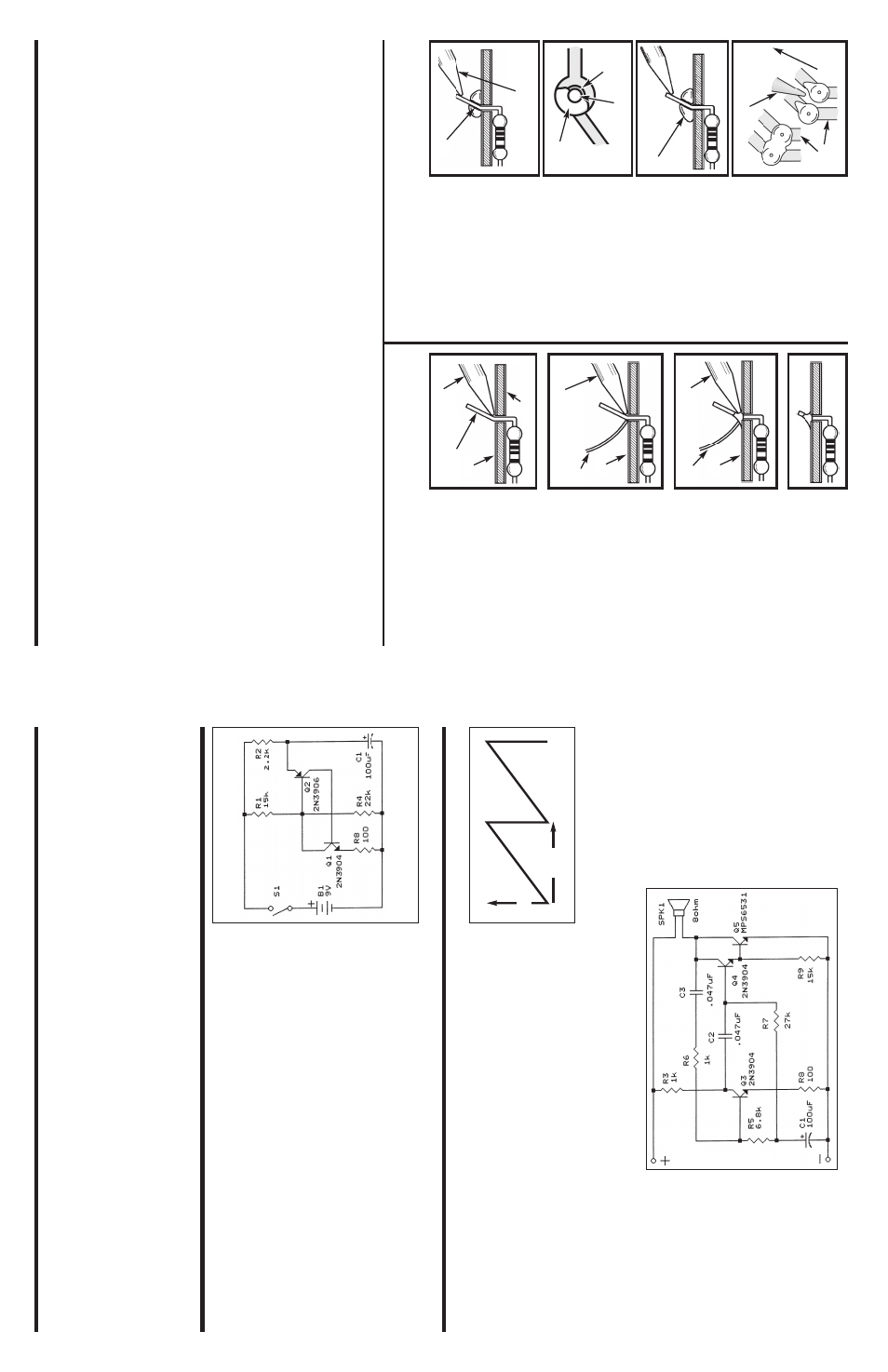

Figure 1

Figure 2

Figure 3

V

olts

Time

CONSTR

UCTION

Solder

Solder

ing Iron

F

oil

Solder

Solder

ing Iron

F

oil

Component Lead

Solder

ing Iron

Circuit Board

F

oil

Rosin

Solder

ing iron positioned

incorrectly

.

Solder

Gap

Component Lead

Solder

Solder

ing Iron

Dr

ag

F

oil

1.

Solder all components from the

copper f

oil side only

. Push the

solder

ing iron tip against both the

lead and the circuit board f

oil.

2.

Apply a small amount of solder to

the iron tip

. This allo

ws the heat to

lea

v

e

the iron and onto the f

oil.

Immediately apply solder to the

opposite side of the connection,

a

w

a

y

from the iron.

Allo

w the

heated component and the circuit

foil to melt the solder

.

1.

Insufficient heat

- the solder will

not flo

w

onto the lead as sho

wn.

3.

Allo

w the solder to flo

w

around

the connection.

Then, remo

v

e

the solder and the iron and let the

connection cool.

The solder

should ha

v

e

flo

w

ed smoothly and

not lump around the wire lead.

4.

Here is what a good solder

connection looks lik

e

.

2.

Insufficient solder

- let the

solder flo

w

o

v

er the connection

until it is co

v

e

red.

Use just enough solder to co

v

e

r

the connection.

3.

Excessive solder

- could mak

e

connections that y

ou did not

intend to betw

een adjacent f

oil

areas or ter

m

inals

.

4.

Solder bridg

e

s

- occur when

solder r

uns betw

een circuit paths

and creates a shor

t circuit.

This is

usually caused b

y

using too m

u

ch

solder

.

T

o

correct this

, simply dr

ag y

our

solder

ing iron across the solder

br

idge as sho

wn.

What Good Soldering Looks Like

A good solder connection should be br

ight, shin

y,

smooth, and unif

or

mly

flo

w

ed o

v

er all surf

aces

.

T

y

pes of P

oor Soldering Connections

Intr

oduction

The most impor

tant f

a

ctor in assemb

ling y

our K-24

Whooper Alar

m Kit

is good solder

ing techniques

. Using the proper solder

ing iron is of pr

ime

impor

tance

. A small pencil type solder

ing iron of 25 - 40 w

a

tts is

recommended.

The tip of the ir

on m

u

st be kept c

lean at all times and

well tinned.

Solder

F

o

r man

y

y

ears leaded solder w

a

s the most common type of solder

used b

y

the electronics industr

y,

b

u

t it is no

w being replaced b

y

lead-

free solder f

o

r health reasons

.

This kit contains lead-free solder

, which

contains 99.3% tin, 0.7% copper

, and has a rosin-flux core

.

Lead-free solder is diff

e

rent from lead solder

: It has a higher melting

point than lead solder

, so y

ou need higher temper

ature f

o

r the solder to

flo

w

proper

ly

. Recommended tip temper

ature is appro

x

imately 700

O

F;

higher temper

atures impro

v

e solder flo

w

b

u

t acceler

ate tip deca

y.

An

increase in solder

ing time ma

y be required to achie

v

e

good results

.

Solder

ing iron tips w

ear out f

a

ster since lead-free solders are more

corrosiv

e

and the higher solder

ing temper

atures acceler

ate corrosion,

so proper tip care is impor

tant.

The solder joint finish will look slightly

duller with lead-free solders

.

Use these procedures to increase the lif

e of y

our solder

ing iron tip when

using lead-free solder

:

•

K

eep the iron tinned at all times

.

•

U

se the correct tip siz

e

f

o

r best heat tr

ansf

e

r.

The conical tip is the

most commonly used.

•

T

ur

n off iron when not in use or reduce temper

ature setting when

using a solder

ing station.

•

Tips should be cleaned frequently to remo

ve

o

xidation bef

ore it becomes

impossib

le to remo

ve

. Use Dr

y

Tip Cleaner (Elenco

®

#SH-1025) or

Tip

Cleaner (Elenco

®

#TTC1).

If y

ou use a sponge to clean y

our tip

, then use

distilled w

a

ter (tap w

a

ter has impur

ities that acceler

ate corrosion).

Saf

e

ty Pr

ocedures

•

Al

wa

ys wear saf

ety glasses or saf

ety gog

gles to

pr

otect y

our e

y

es when w

orking with tools or

soldering ir

on,

and during all phases of testing.

•

B

e sure there is

adequate ventilation

when solder

ing.

•

Locate solder

ing iron in an area where y

ou do not ha

ve

to go around

it or reach o

ver it.

K

eep it in a saf

e

area a

w

a

y

from the reach of

children.

•

Do not hold solder in y

our mouth.

Solder is a to

xic substance

.

W

a

sh hands thoroughly after handling solder

.

Assemb

le Components

In all of the f

ollo

wing assemb

ly steps

, the components m

u

st be installed

on the top side of the PC board unless otherwise indicated.

The top

legend sho

w

s where each component goes

. The leads pass through the

corresponding holes in the board and are soldered on the f

oil side

.

Use onl

y r

o

sin core solder

.

DO NO

T USE A

C

ID CORE SOLDER!

'