Warning – EarthQuake W1265V User Manual

Page 21

Operator's Manual

Trail Warrior Quick Split 12-Ton Log Splitters

Check for parts online at www.getearthquake.com or call 800-345-6007 M-F 8-5

21

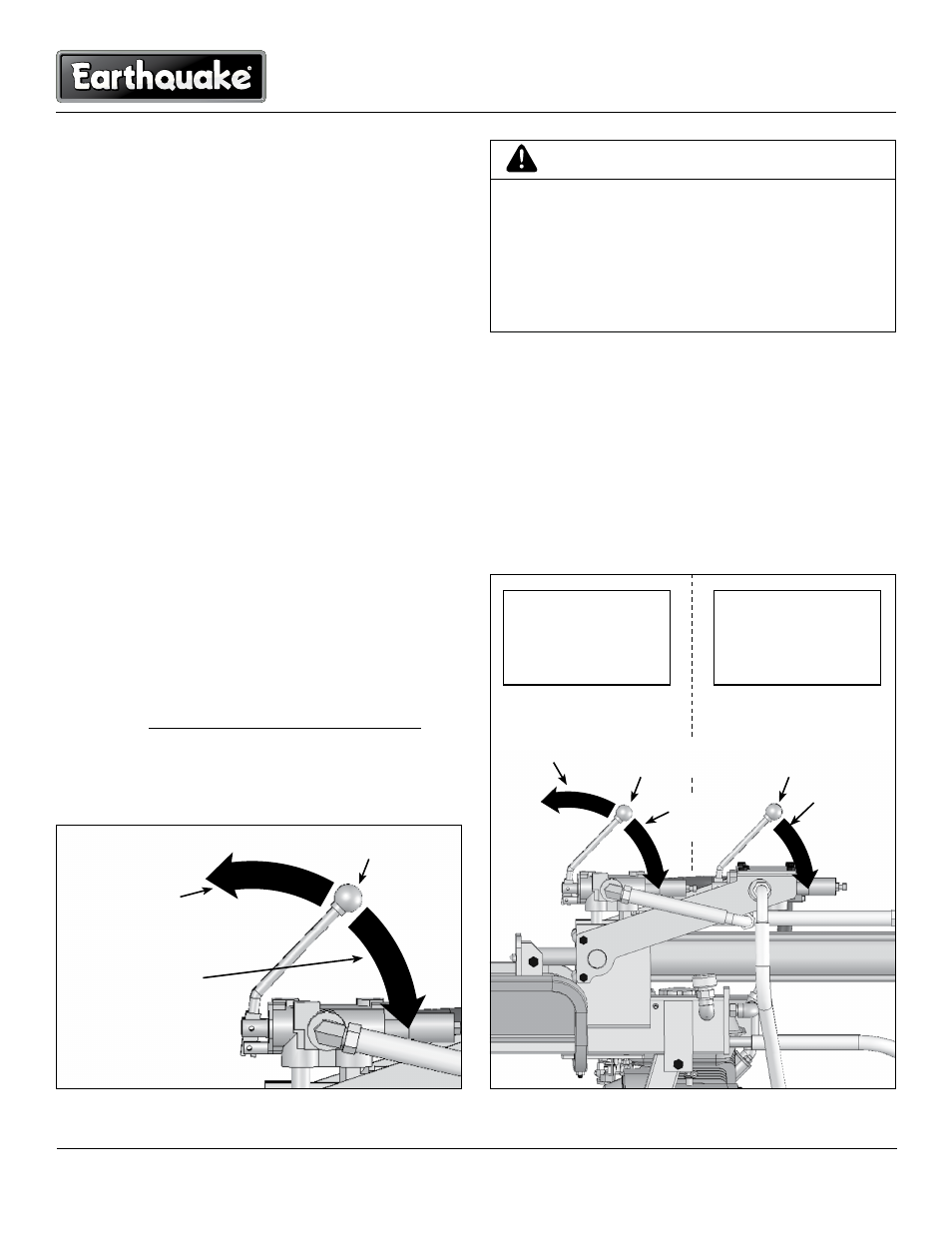

5. Move control lever forward to extend the hydraulic cylinder all

the way. (It is normal for the cylinder to not move smoothly as it

purges the air from the system.) SEE FIGURE 25. For European

models with two valves, while holding the (rear) Flow Control

valve lever in the rearward position with one hand, use the other

hand to move the (front) Direction Control valve lever forward

to extend the hydraulic cylinder all the way. SEE FIGURE 26.

6. Move control lever to the return position until ram is retracted

fully. On European log splitter models with two valves, the

(rear) Flow valve lever must be held in the rearward position

in order for the (front) Direction Control valve lever to retract

the ram when moved rearward.

7. Turn off engine.

8. With cylinder in the return position with the air bleeder valve

still in the open position, open the filler cap very slowly to

allow any air to escape that may have been trapped in the

reservoir during the initial filling procedure.

9. Top off the reservoir by adding up to 3 more quarts of hydraulic fluid.

NOTE: Some units may not take the complete 3 quarts as

they were filled and tested at the factory prior to shipment

and some residual fluid still remains in the hydraulic system.

Your Trail Warrior is now properly filled and ready for use. You

have the correct amount of fluid in the reservoir when you can

see the fluid inside the fill spout. Some fill caps are equipped

with dipstick for checking fluid level.

Once the log splitter is filled with fluid you can close the air

bleeder valve by turning it all the way clockwise.

TIp: If your ram still does not travel smoothly, there may still be

air in the hydraulic system or your fluid level is too low. If this is

the case, with the engine turned off and the filler cap on, open

your air bleeder valve and move the hydraulic control valve

from the forward to return position a few times to purge any

air that may be trapped in the hydraulic system.

NOTE: Doing this procedure with the filler cap removed will

cause any air that is in the system to expel through the filler

spout. Check for proper fluid level.

SySTEM CHECk:

With the correct amount of hydraulic fluid in the system, oper-

ate the cylinder ram all the way into the forward direction and

all the way in the return direction. Check that the ram moves

smoothly without jerking. Check that there is no leaking of fluids

at component ports, fittings, or hoses. If leaking is found, tighten

fittings or clamps until leaking goes away. If leaking doesn't go

away, contact Ardisam Customer Service (800-345-6007 M-F

8:00-5:00 PM CST, or e-mail [email protected]).

Figure 25: US Version

FORWaRD

(Splitting Direction)

REaRWaRD

(Return Direction)

NEUTRaL

POSITION

Figure 26 European Version

FORWaRD

(Splitting Direction)

REaRWaRD

(Return Direction)

DIRECTION

CONTROL VaLVE

(FRONT VaLVE)

W1265V0700ACE

NEUTRaL

POSITION

REaRWaRD

ONLy

(Flow On)

NEUTRaL

POSITION

FLOW

CONTROL VaLVE

(REaR VaLVE)

W1265V0700BCE

WaRNING

FLUID ESCaPING FROM a VERy SMaLL HOLE CaN BE

VERy DIFFICULT TO SEE. DO NOT CHECk FOR LEakS

WITH yOUR HaND. ESCaPING FLUID UNDER PRES-

SURE CaN HaVE SUFFICIENT FORCE TO PENETRaTE

SkIN, CaUSING SERIOUS PERSONaL INJURy OR EVEN

DEaTH. LEakS CaN BE LOCaTED By PaSSING a PIECE

OF CaRDBOaRD OR WOOD OVER THE SUSPECTED

LEak. LOOk FOR DISCOLORaTION.