Troubleshooting – Ditch Witch FM13V User Manual

Page 41

FM13V - TROUBLESHOOTING

41

PUMP

FM13V - TROUBLESHOOTING

41

PUMP

TROUBLESHOOTING

The FM13V has a metering plate in the bottom of the dry

chemical hopper sized to match material flow to fluid volume

going through venturi. This plate helps each unit maintain the

approximate time required to feed 50 lb (22.7 kg) of material into

tank when engine is running at full speed. Changing material flow

rate by removing or resizing plate will affect mixing results.

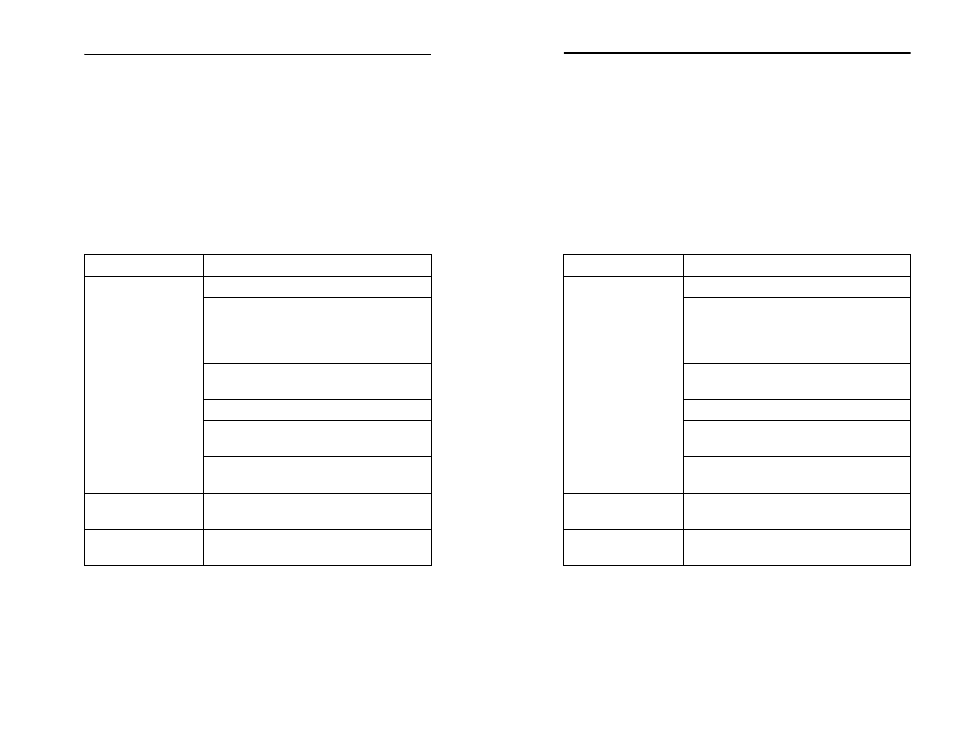

Problem

Possible solutions

Slow feed rate from

hopper

Run engine at full speed

Place control valves in recommended

mixing positions.

Clear obstructions from metering plate

and check that screen is in place.

Remove build-up from venturi chamber.

Clean plugged hoses and fittings. Repair

or replace damaged hoses and fittings.

See pump instructions for procedure on

checking flow.

Poor drilling fluid

mix characteristics

Test water pH and treat if necessary (see

PREPARATION for instructions).

Clumps in drilling

fluid tank

Check feed rate.

TROUBLESHOOTING

The FM13V has a metering plate in the bottom of the dry

chemical hopper sized to match material flow to fluid volume

going through venturi. This plate helps each unit maintain the

approximate time required to feed 50 lb (22.7 kg) of material into

tank when engine is running at full speed. Changing material flow

rate by removing or resizing plate will affect mixing results.

Problem

Possible solutions

Slow feed rate from

hopper

Run engine at full speed

Place control valves in recommended

mixing positions.

Clear obstructions from metering plate

and check that screen is in place.

Remove build-up from venturi chamber.

Clean plugged hoses and fittings. Repair

or replace damaged hoses and fittings.

See pump instructions for procedure on

checking flow.

Poor drilling fluid

mix characteristics

Test water pH and treat if necessary (see

PREPARATION for instructions).

Clumps in drilling

fluid tank

Check feed rate.