Dillon Precision Square Deal 'B' User Manual

Page 11

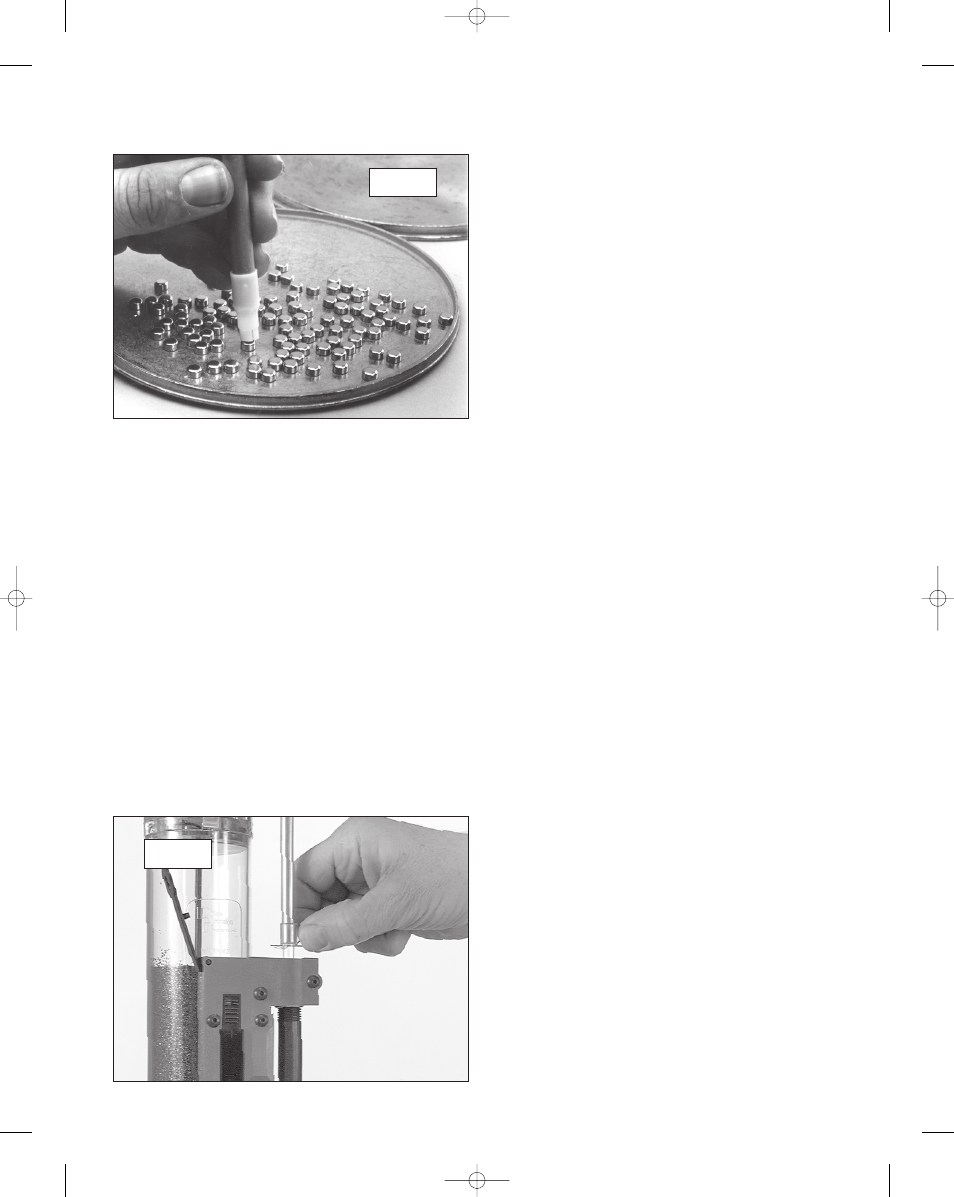

pick up the primers, shiny side up as shown in Fig. 16.

This tube will hold approximately 100 primers.

You will notice that the primer magazines and primer

pick-up tubes have different colored tips. They have been

color coded to help you identify size more easily.

The color code is as follows:

Blue

Small Primer Magazine Orifice

Red

Large Primer Magazine Orifice

Yellow

Small Primer Pick-up Tube

Green

Large Primer Pick-up Tube

Primers are much easier to pick up if you use a primer

flip tray. A quality metal tray is available from Dillon

Precision.

Never forget that primers are potentially dangerous.

Never hit them or attempt to force them.

Primer Early Warning System Installation

(See page 4 for assistance.) Install the battery and the

battery cover (#13857) in the system’s main body. Slide

the Early Warning System Assembly down over the

knurled cap on your primer magazine and lightly tighten

the clamp screw.

Pivot the switch lever (#13864) away from the Early

Warning System housing to fill the primer magazine with

primers.

Invert the primer pick up tube over the knurled cap

and pull the primer retaining clip (#14040 – See Fig. 17.)

The primers should now fall smoothly into the magazine.

Pivot the switch lever back over the Early Warning System

housing. Gently slide the follower rod (#13707) down

through the switch lever, the knurled cap and into the

primer magazine tube until the follower rod touches the

primers.

You are now ready to reload. When you are nearly out

of primers (approximately three remaining) the follower

rod will activate the buzzer. Never attempt to remove the

primer magazine shield, it is there for your protection.

Your primer system should now be ready. Let’s move on to

Station 3.

Station 3: This is an easy one. All we do is seat the

bullet to its proper depth in the cartridge case. This depth

was adjusted at the factory for the bullet type on the

sample cartridge.

We give you a choice of bullet seating stems, use the

one closest to the type of bullet you are using.

The depth of bullet seating may be adjusted simply by

screwing the seating stem in or out. The adjustment is

held in place by a layer of Delrin beneath the toolhead.

Station 4: Another easy one. This station removes the

bell and crimps the bullet in place. Once again this

adjustment has been performed by Dillon.

More or less crimp can be achieved simply by

screwing the crimp adjustment screw (#13908) in or out.

Check your reloading manual for crimp dimensions.

Load ‘em up

Okay now that you understand the purpose of all of

the Square Deal “B” stations, we are ready to reload.

Begin as follows:

1.) Place a clean, empty case in Station 1 and cycle

the handle, don’t forget to press forward firmly to seat the

primer in Station 2. Work slowly.

2.) Place another empty case in Station 1, cycle the

handle. Work slowly and carefully, watch the powder bar

function and be sure it travels fully to the left each time. If

it doesn’t, turn the powder die (#13865) 1/8 turn

clockwise and try again.

3.) Carefully place a bullet on top of the cartridge case

at Station 3. Insert a new empty case at Station 1, cycle

the handle.

4.) From this point on, place a bullet on the case at

Station 3 with your left hand. Insert a case at Station 1

with your right hand and cycle the handle. Each time you

cycle the machine a finished round will be ejected into

the cartridge collection bin. (See Fig. 18 next page)

Fig. 17

Fig. 16

11

May 2007 Square Deal B Manual 5/17/07 2:23 PM Page 11