Dillon Precision RL 550B User Manual

Page 12

Note: If you screw the die down too far the case will look

like example “C” FIG 22. You must then discard this case,

back the powder die off, by turning it counter-clockwise,

and continue with a new sized case.

You’ll soon learn to judge the correct amount of bell by

simply looking at it. In the meantime, you might want to use

your dial calipers to check it. Twenty thousandths of an inch

greater (at the mouth of the case) than its original diameter,

should about do it.

Once you’ve achieved the desired amount of bell – with

the case in Station 2, raise the platform. Turn the die lockring

down hand tight.

Be aware that new brass will often “stick” on the powder

funnel or cause resistance on the upstroke. Cleaning the

brass in a tumbler should help.

Next, attach the powder measure fail safe rod assembly

to the bellcrank (#17839).

Using your thumb and index

finger of your right hand, move the lock-link down to

align the hole with the slot on the Powder Measure

bellcrank (#17839). Then insert the rod (#97000) through

the two holes, Fig. 20. Next,

lower the operating handle

(#20636). Insert the powder measure rod into the slot in the

return bracket (#13885) press the shoulder washer into the

slot from the bottom. Move the operating handle to the

priming position, press the operating handle firmly forward.

Tighten the blue wingnut (#13799) until the top of the spring

(#14033) just touches the underside of the return bracket

(#13885). Release the operating handle to the up/rest

position. Now, tighten the screws on the body collar clamp

(#13939).

We’ll come back to filling the measure with powder and

adjusting the bar. The purpose of the powder measure

failsafe rod (#97000) is to return the powder bar to its closed

position.

Station Three

In this station the bullet is seated to its proper depth. You

need to refer to a loading manual for overall length of the

completed round. Overall length (OAL) may vary up to

.016”, and this is normal.

Put a case into the shellplate at Station Three. Raise the

platform up and screw the die down until it just touches the

shellplate and back it out two turns. Now, back your seating

stem out.

Place a bullet on the case and operate the handle. Using

a dial caliper or case gage, check for overall length. Keep

screwing the seating stem down in small increments until the

correct overall length is achieved. Once you are satisfied

with the overall length, tighten the lock ring.

Station Four

The crimping operation is performed at this station.

Insert the crimp die and place an empty case in Station

Four. Raise the platform and screw the crimping die down

until it touches the rim of the case. Now lower the platform

and screw the die down an additional one-quarter of a turn.

Place a round in Station Four with a seated bullet and cycle

the operating handle.

You will need to refer to a loading manual to get proper

crimp dimensions for the caliber you are loading. A dial

caliper is required to take accurate measurements from your

crimped round.

If more crimp is needed, screw the crimp die down in

small increments until you get the desired crimp, now

tighten the lock ring.

* Indicates a caliber specific part. See the caliber conversion

chart on page 16 for the caliber you are loading for.

12

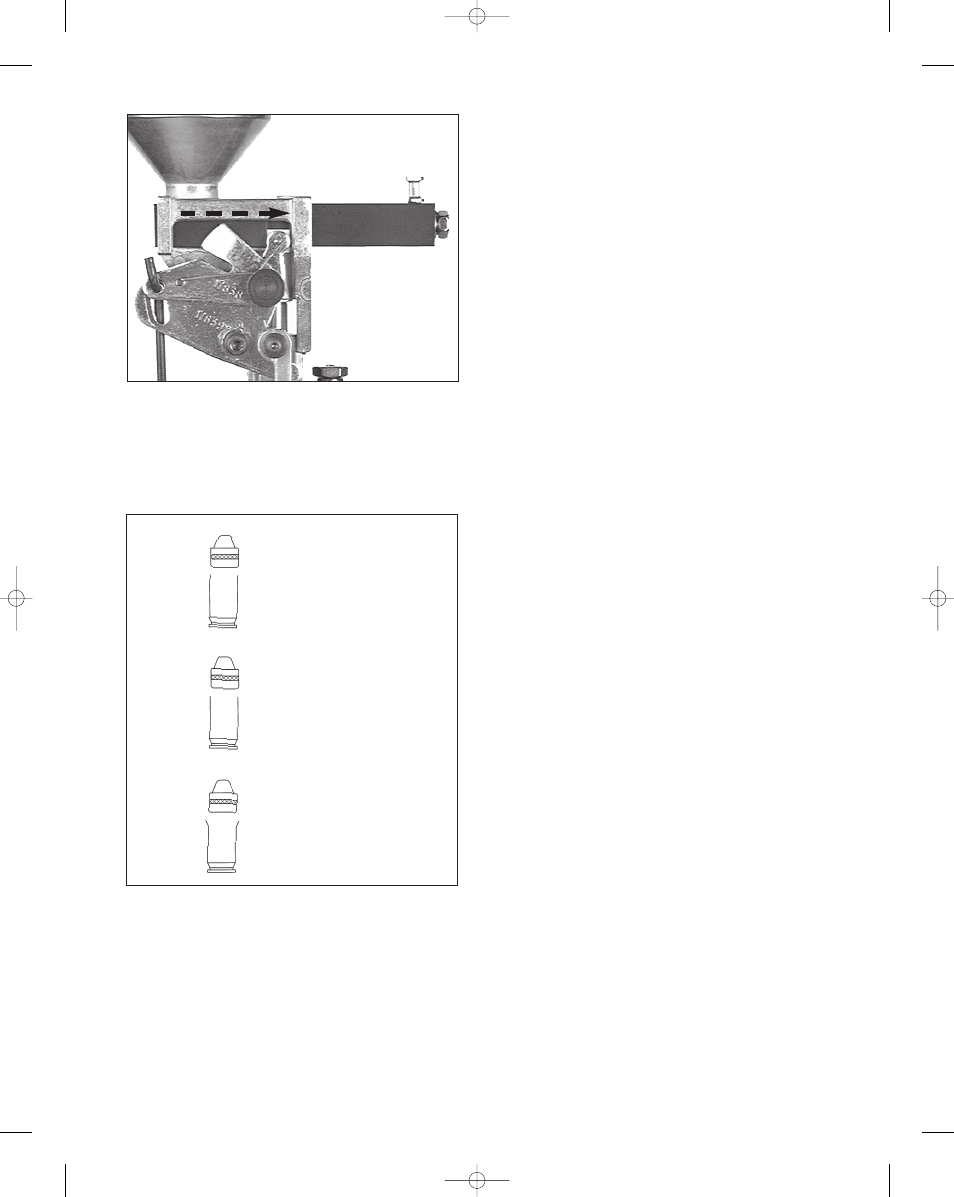

A

Correct amount of

bell.

B

Not enough bell.

C

Too much bell.

Fig. 22

Fig. 21 - This photo shows the large powder bar in its fully

open (rearward) position. Note the position of the white

bellcrank cube. (Primer system removed for clarity.)

RL 550B, May 2007 5/17/07 2:21 PM Page 12