Curved multi format imager assembly – Da-Lite Curved Multi Format Imager User Manual

Page 5

5

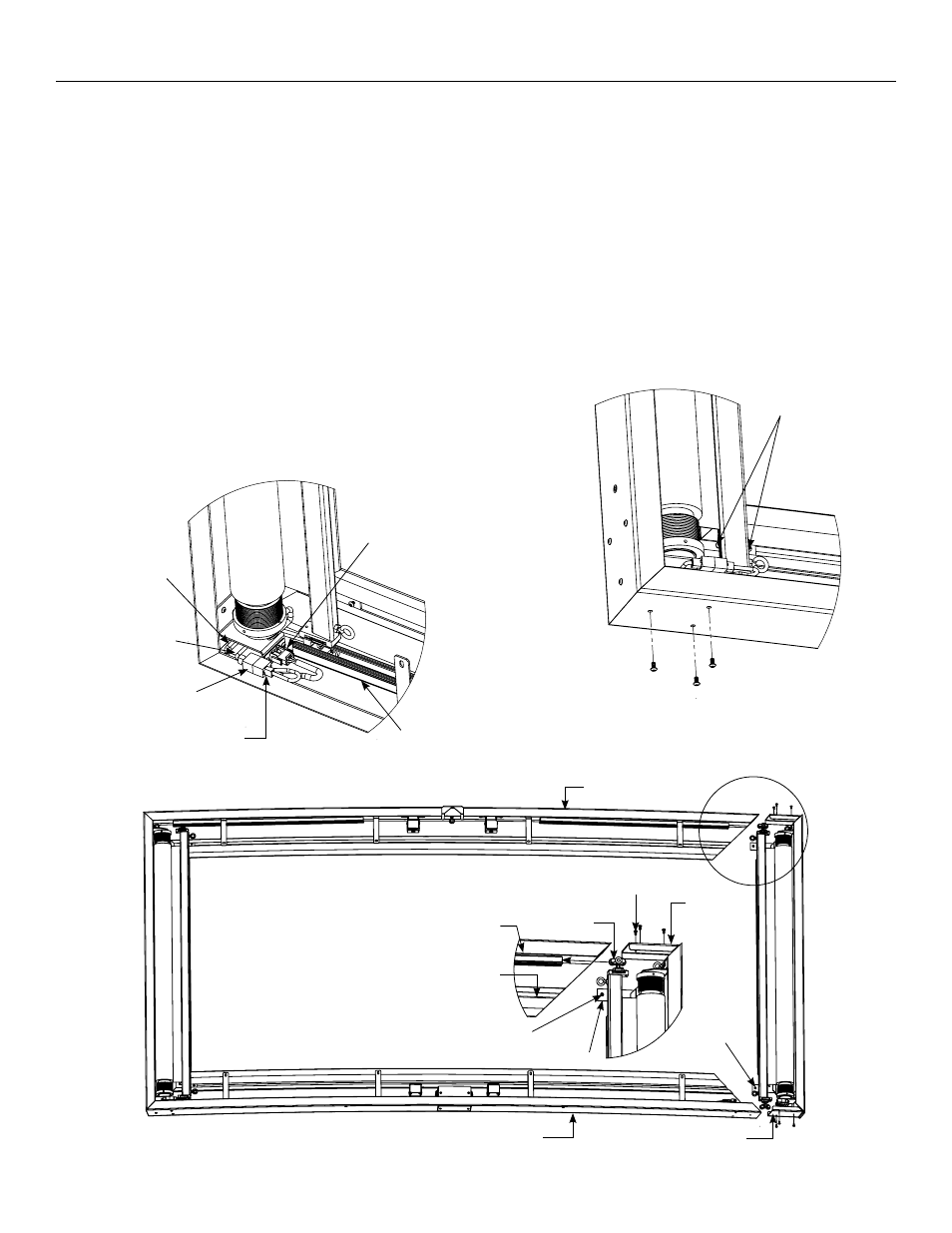

4. Assemble bottom end of left frame assembly to end of

bottom frame assembly. The large L-bracket will slide into the

aluminum extrusion while the small L-bracket will slide into

the frame channel. When sliding the bracket into the bottom

frame assembly, guide the slat roller carriage into the bottom

aluminum guide track. See Figure 5.

5. Route the two cable assemblies around motor bracket and

plug the 3 wire male connector into the 3 wire female

connector on the motor bracket. The motor will have a gray

data cable with and RJ-45 connector and RJ-45 coupler on

the end coming out of the head of the motor. Plug the

connector of the cable assembly into the RJ-coupler. Tuck the

RJ- coupler underneath motor bracket securely to prevent

entanglement as shown in Figure 5.

6. Fasten (3) #10 x 3/8” button head screws through bottom of

frame into the large L-bracket. Tighten two screws on flat

small L-bracket to line up the front surfaces. See Figure 6.

7. Assemble right side of frame to top and bottom frame

assemblies. The two large L-brackets will slide into top and

bottom aluminum extrusion while the two small L-brackets

will slide into the frame channel. When sliding the right side

assembly into the aluminum extrusion, guide the slat roller

carriage into the top and bottom aluminum guide tracks as

shown in Figure 7.

8. Fasten (3) #10 x 3/8” button head screws through top and

bottom of frames into the large L-brackets. Tighten two

screws on each flat small L-bracket to line up the front

surfaces.

Curved Multi Format Imager Assembly

Large

L-Bracket

Large

L-Bracket

Small

L-Bracket

Small L-Bracket

Aluminum

Guide Track

Frame Channel

Bottom Frame Assembly

Make Sure Carriage

Rollers Are Seated

Properly in Guide Track

Fasten Screws Through Top Frame

Assembly Into Large L-Bracket

Tighten Screws Until

Front Surfaces Are Flush

Slat Roller

Carriage

Top Frame

Assembly

Figure 7

Aluminum

Guide Track

Plug Motor

Power In

Tuck Excess Wire

Underneath

Motor Bracket

Data Cable From

Motor Head

Tuck RJ-45 Coupler

Underneath

Motor Bracket

Plug Connector

Into Coupler

Figure 5

Fasten Screws

Through Bottom

Frame Assembly

Into Large L-Bracket

Tighten Screws

Until Front

Surfaces Are

Flush

Figure 6