English, Troubleshooting, Lens units – Clay Paky TIGER C.C. User Manual

Page 3: Maintenance

7

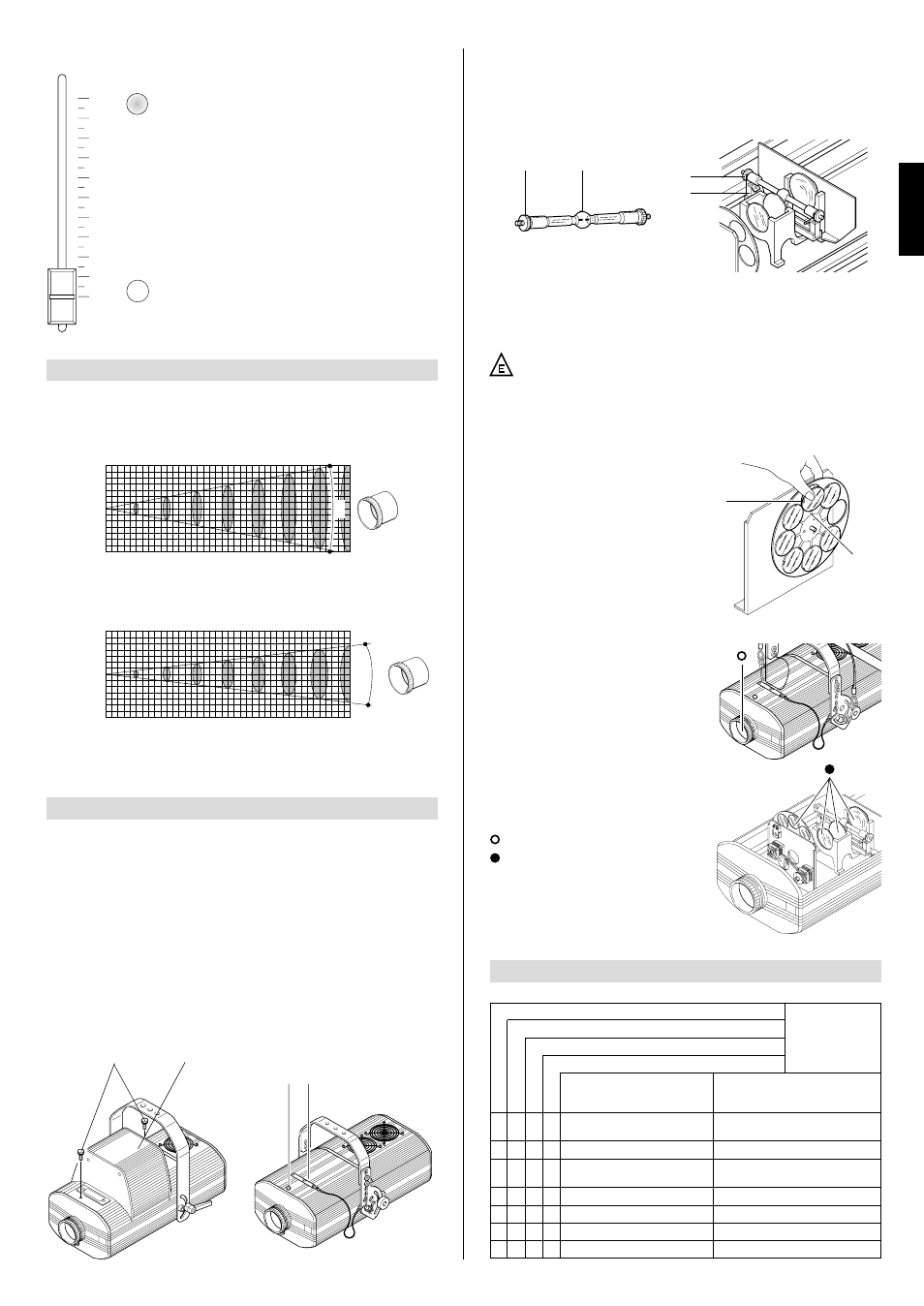

• Changing the colour filters

Having opened the projector, identify the fil-

ter to be changed, grip firmly between

thumb and forefinger and push against the

spring clip (23) until free of the fixed clips

(24). Bend the filter outwards and remove.

Offer the new filter to the spring clip (23)

and anchor behind the two fixed clips (24).

• Routine cleaning

To maintain the light output of the projec-

tor undiminished, parts that tend to accu-

mulate dust and grease must be cleaned

periodically.

In most circumstances, the projector will

give long and trouble-free service if these

simple guidelines are followed.

To remove dirt from the lenses and filters,

use a soft cloth moistened with any liquid

detergent suitable for cleaning glass.

IMPORTANT: do not use solvents or alcohol

Parts that need cleaning frequently.

Parts that need cleaning monthly.

Internal components should also be given

a general clean once a year, dislodging

dust and dirt with a brush and removing it

simultaneously with a vacuum cleaner.

TROUBLESHOOTING

7

0

1

2

3

4

5

6

7

8

9

10

• FROST - channel 3

The frost filter is inserted gradually as

the slider is advanced.

LENS UNITS

5

GRAPHS SHOWING BEAM DATA AND ILLUMINATION VALUES

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

BEAM OPENING m

0

5

10

15

20

25

30

35

40

DISTANCE m

0

1,87

3,74

5,61

7,48

9,35

11,2

13,10

14,96 DIAMETER m

HMI 575

3.600

HMI 1200 8.600

900

2.150

400

955

225

537

144

100

73

56

LUX

344

238

175

135

Objective 1:1,8 / 170 - Standard

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

BEAM OPENING m

0

5

10

15

20

25

30

35

40

DISTANCE m

0

1,16

2,32

3,48

4,64

5,80

6,96

8,12

9,28 DIAMETER m

HMI 575

8.200

HMI 1200 19.800

2.050

911

512

328

227

167

128

Objective 1:2,5 / 250

LUX

4.950

2.200

1.237

792

550

404

309

13

°

21

°

0”

6’ 2”

DIAMETER ft in

12’ 3”

18’ 5”

24’ 6”

30’ 8”

36’ 9”

43’

49’ 1”

0”

16’ 5”

DISTANCE ft in

32’ 10”

49’ 3”

65’ 7”

82’

98’ 5”

114’ 10”

131’ 3”

0”

16’ 5”

DISTANCE ft in

32’ 10”

49’ 3”

65’ 7”

82’

98’ 5”

114’ 10”

131’ 3”

0”

3’ 10”

DIAMETER ft in

7’ 7”

11’ 5”

15’ 3”

19’

22’ 10”

26’ 8”

30’ 5”

MAINTENANCE

6

IMPORTANT: isolate the projector from the electrical power supply before com-

mencing maintenance work of any description. The maximum temperature on the

outer surface of the projector under normal operating conditions is shown on the lamp

change label. After switching off, do not remove any part of the projector for at least

2 minutes, as indicated on the lamp change label (1).

Once this time has elapsed, the risk of a lamp exploding is practically zero. If the lamp

needs changing, wait a further 20 minutes to avoid the risk of burns.

In the event of a lamp exploding, the appliance is designed to prevent fragments of

glass from being scattered. The lenses supplied with the appliance must be fitted at

all times, and if visibly damaged, must be replaced with genuine spares.

• Opening the projector

Loosen the knobs (19) and remove the lamp access cover (13). Once the necessary

work has been completed, refit the cover and tighten the knobs.

19

13

19 13

• Changing the lamp

Open the projector, loosen the two side nuts (20) of the lamp to be changed and

remove it from the supports (21).

Remove the new lamp from its box, loosen the two side nuts (20) and locate the lamp

in the supports (21). Finally, retighten the nuts.

IMPORTANT: for uniform distribution of the light beam, the lamp must be posi-

tioned so that the glass pip (22) on the bulb does not coincide with the optical axis

of the projector. With this in mind, locate the pip as high up as possible.

CAUTION: The projector uses a high pressure lamp with external starter.

- When fitting a new lamp, read the manufacturer's instructions carefully.

- The lamp must always be changed without delay if damaged or deformed

by heat.

20

21

20

22

24

23

ENGLISH

No electrical power supply.

Check that power is available at the mains

socket.

Signal transmission cable short-cir-

cuiting or disconnected.

Change cables.

PROJECTOR DOES NOT LIGHT UP

ELECTRONICS NOT WORKING

FAULTS

PROJECTION FAULTY

REDUCED BRIGHTNESS

POSSIBLE CAUSES

CHECKS AND REMEDIES

•

•

•

•

•

•

• •

•

Lamp expended or faulty.

Change lamp (see instructions).

Address codes incorrect.

Defect in electronic circuits.

Lenses broken.

See projector coding instructions.

Contact an authorized technician.

Contact an authorized technician.

Dust or grease deposit.

Clean (see instruct ions).