Special features koko xtra 2.0, Operation with external air supply, Xtra heat storing technology – Austroflamm Koko Xtra 2.0 User Manual

Page 10: Problem possible reason solution

Koko Xtra 2.0

8

english

5. SPECIAL FEATURES KOKO Xtra 2.0

Xtra heat storing technology

The model KOKO Xtra 2.0 has been equipped with the unique Xtra heat storing technology. This technology is based on the

patented Heat Memory System, but also on the special flue gas guidance and the convection air which can be regulated or

shut off completely. Consequently a fast heating system is being combined with an extraordinarily efficient heat storing.

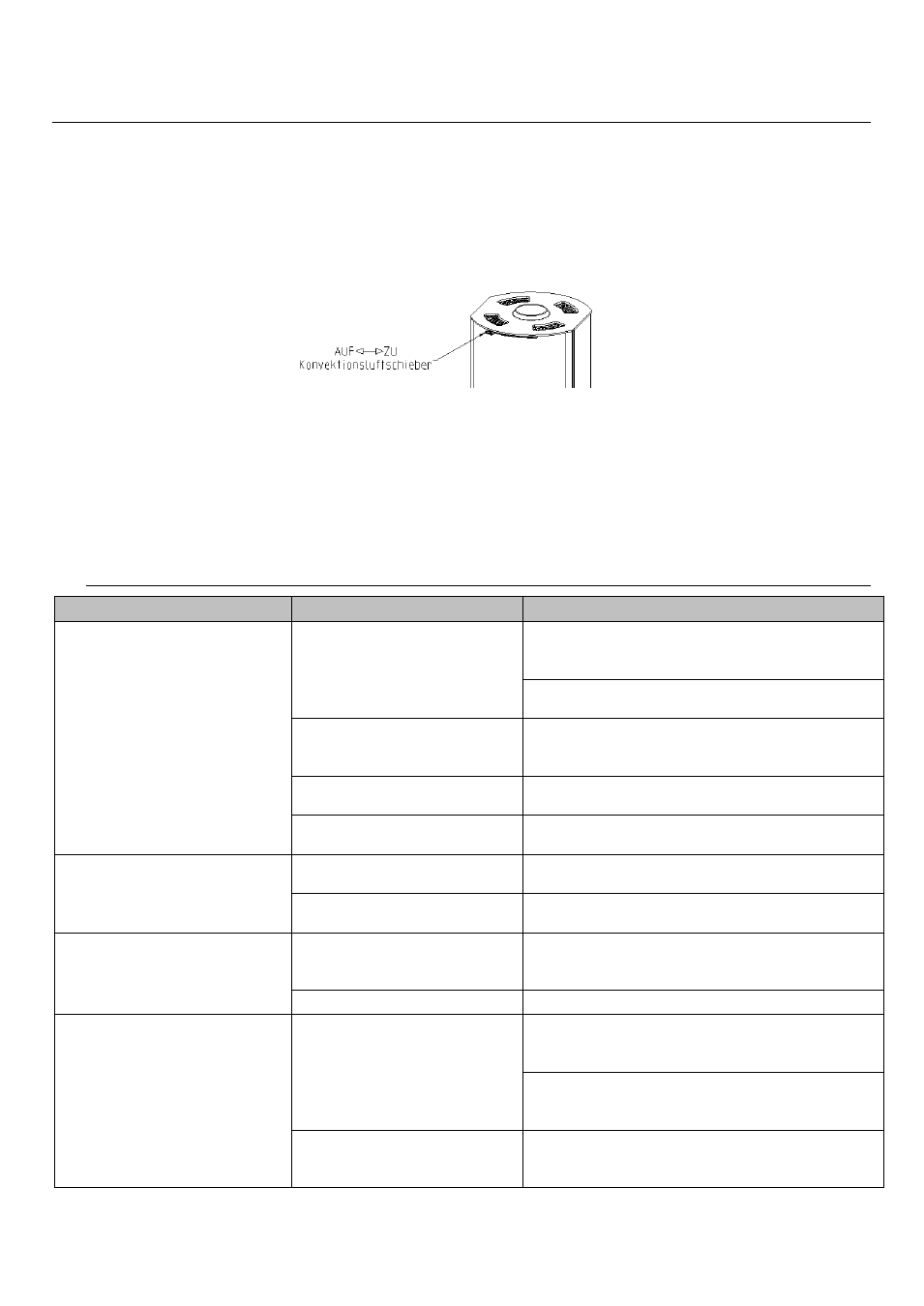

The convection air can be regulated according to demand with the attached lever (see picture). The more the convection air

outlets of the top plate are open, the faster heat but less heat storing can be reached. A closed top plate will however lead to

slow heat and longer heat storing.

Our hint: while the fire still burns let the convection air outlets open; close them after the fire has burnt down in order to

reach a steady heat emission.

Operation with external air supply

Koko Xtra 2.0 can be operated with an external air connection. If the combustion air is being supplied directly to the furnace

by an air-tight pipe including closing mechanism from the outside, then the stove may be used in residential property with

mechanical ventilation.

Attention – all gaskets must be inspected periodically for tightness and have to be replaced if necessary.

If the stove in being used like that, a multiple stove installation on the same chimney is forbidden.

This stove has been approved by the German DIBT

.

problem

possible reason

solution

door glass gets sooty too fast

generally: door glasses must be cleaned with

Austroflamm glass cleaner from time to time (depending

on the frequency of use)

bad chimney draught

contact your chimney sweep (elongate chimney/draught

metering)

incorrect use of the combustion air

supply lever

please operate air lever according to user's instructions

(if secondary air is closed, the door glass soots rather

fast)

wood logs are too large

keep to the max. fuel quantity according to user's

instruction

operating temperature was not

reached

more fuel, use dry wood (< 15 % residual moisture),

attend air regulation

stove does not get enough

combustion air

chimney draught not sufficient

contact your chimney sweep (elongate chimney/draught

metering)

stove is sooted inside

more fuel, use dry wood (< 15 % residual moisture),

attend air regulation

stove smells strongly and there is

smoke on the outside surface

baking phase of the varnish

there may be some odour development during the first

operations

stove is dusty/dirty

cleaning before the heating season starts!

exhaust gas emission while putting

more wood on the fire and during

operation

inspect joints and seal up again if necessary

chimney draught no sufficient, flue

pipe connection leaky

check chimney draught, examine operating - for info

video follow:

http://www.austroflamm.com/de/Video/index.html

the stove door was opened before

the wood has burnt down to

embers

put more fuel wood into the combustion chamber only if

there are only embers left (no more visible flame)